In the world of CNC machining, precision is the key to success, and this precision is closely related to the selection and setting of tools. The right tool is like a perfect key that unlocks the door to efficient machining, enhancing not only machining accuracy but also significantly improving the quality of the final product. Compared to traditional machine processing, CNC machining allows programmers to simply set parameters through human-machine interaction, automatically generating programs and transmitting them to the machine. This shift makes the entire machining process more intelligent, but it also presents new challenges for programmers.

In this process, programmers need a deep understanding of tool selection and cutting parameters to fully leverage the advantages of CNC machining. Have you ever felt confused about tool selection or unsure about how to set cutting parameters? These are common issues that every practitioner may encounter in their daily work. This article will provide you with practical principles and suggestions to help you better address these challenges in programming and operation.

What Is Tool Setting In CNC?

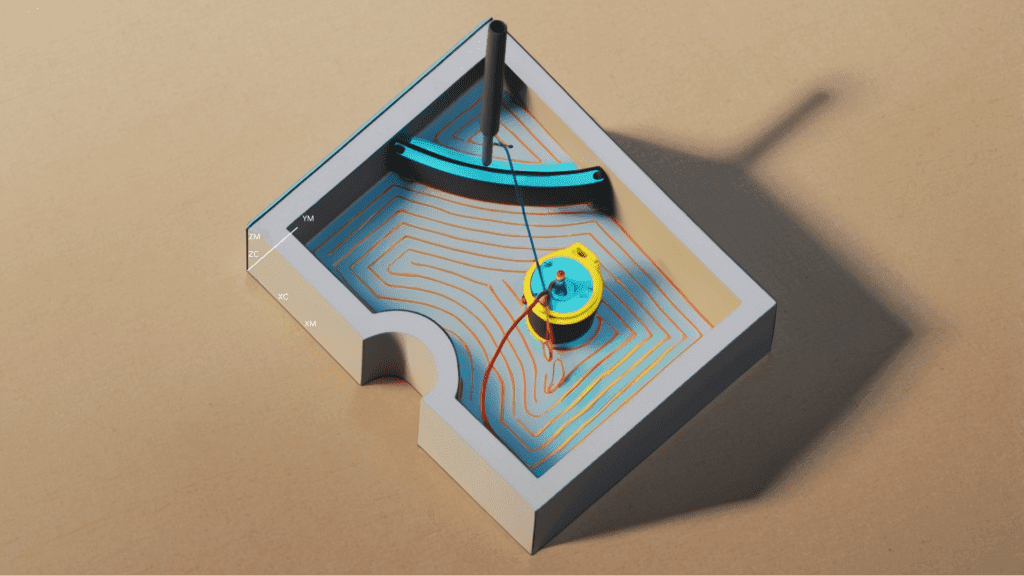

CNC tool setting is a crucial step in ensuring maximum accuracy during the machining process, involving the coordination of positions between the workbench, tools, and workpieces. Each component must maintain an exact dimensional relationship, which not only affects machining efficiency but also directly impacts the quality of the final product. Therefore, a well-structured CNC tool setting procedure is particularly important. These procedures typically include detailed alignment and calibration steps to ensure that the tools and workpieces are in optimal condition before machining begins. During this process, even the slightest error can lead to deviations in the machining results, so operators must strictly adhere to the established procedures to ensure that all components are perfectly aligned and positioned.

What Are The Methods For Tool Setting?

The usual tool setting methods in CNC machining are essential for achieving precise and efficient machining results.

Trial Cutting And Tool Alignment: This basic method involves making a small cut on the workpiece to establish the tool’s position. After adjusting the tool settings on the X and Y axes, the workpiece is installed, and the center is located. The operator makes a slow cut into the side of the workpiece and records the X and Y coordinates. This method can also be adapted to obtain the Z-axis coordinate by using an end mill for trial cutting.

Feeler Gauge Tool Alignment: This method involves placing a feeler gauge between the tool and the workpiece without rotating the tool, thus leaving no marks on the workpiece. When calculating coordinates, it’s essential to subtract the thickness of the feeler gauge. While this method is straightforward, it may not provide high precision.

Using Edge Detectors Or Eccentric Rods: A popular and accurate method for CNC tool setting is using edge detectors or eccentric rods instead of trial cutting. The steel ball part of the tool should make slight contact with the workpiece. It’s important to use conductive materials for the workpiece and ensure the reference surface is rough for better accuracy.

Top Tool Setting Method: Similar to the trial cutting method, this technique involves cutting into the top of the workpiece instead of the side. The tool settings on the X and Y axes are adjusted, the workpiece is installed, and the center is located. A slow cut is made into the top of the workpiece, and the X and Y coordinates are recorded.

Indirect Tool Alignment: This method is used when multiple tools are involved in CNC machining, especially when the length of the second tool differs from the first. It requires resetting the original tool’s offset for the additional tool without damaging the workpiece surface.

Using Dedicated Tool Aligners: Traditional tool alignment methods can be time-consuming and prone to error, which may disrupt the machining process. Dedicated tool alignment devices enhance safety and efficiency, simplifying the process and improving overall accuracy.

Dial Indicator Tool Setting: This method involves using a dial indicator mounted on the tool spindle. The worktable is moved to position the spindle’s centerline near the workpiece center, and adjustments are made. The spindle is rotated slowly, allowing the indicator’s probe to trace the circumference of the workpiece, providing precise coordinates for tool setting.

Principles Of Tool Selection

The general principles for tool selection are: easy installation and adjustment, strong rigidity, high durability, and high precision. While meeting processing requirements, the length of the tool holder and other parameters can be appropriately selected.

- Material Compatibility: Choose tools that are appropriate for the material being machined.

- Tool Geometry: Consider the geometry of the tool, including cutting edge design, rake angle, and flute shape. These factors influence cutting performance, chip evacuation, and surface finish.

- Cutting Conditions: Evaluate the cutting parameters such as speed, feed rate, and depth of cut. The selected tool should be capable of operating effectively within these parameters.

- Tool Life: Assess the expected tool life based on wear resistance and durability. Longer tool life reduces downtime and overall production costs.

- Application Requirements: Match the tool to the specific machining operation (e.g., milling, turning, drilling) to achieve the best results for that process.

- Cost-Effectiveness: Consider the balance between tool performance and cost. Sometimes investing in higher-quality tools can lead to better efficiency and lower long-term costs.

- Availability: Ensure that the selected tools are readily available. Delays in sourcing tools can impact production schedules.

- Safety Considerations: Choose tools designed with safety features to minimize the risk of accidents during operation.

During milling, choosing climb milling over conventional milling can reduce tool stress and vibration, ensuring better surface finish and extending tool life. In the drilling process, promptly clearing drill chips can prevent accumulation on the tool, which may affect cutting performance. For example, regularly pausing the machining process to use an air gun to clean debris from the workbench and around the tool is advisable.Throughout the machining process, it’s important to record tool usage and machining parameters, followed by a summary analysis post-processing to determine which adjustments yield the best results for future optimizations.

The positioning relationship of tool setting is crucial; the tool tip must maintain a known precise relationship with the part’s reference datum to ensure machining accuracy. In cases where high precision is required, it’s advisable to select an appropriate tool tip based on design or technical foundations. For hole-shaped parts, the center of the hole can serve as a tool tip, providing precise positional reference. Additionally, the tool tip must align with the tool position to serve as a reference point for determining the tool’s location. Different tools have varying tip positions; for instance, the tip of a flat end mill is located at the center of the cutting plane, while the tip of a ball end mill is at the center of the sphere, and the tip of a drill bit is at its pointed end.

The configuration of tool change points should be based on the process content, fixed in a position away from the workpiece, without necessarily adhering to the principles of the workpiece, fixture, or machine tool. Since the precision of the tool directly impacts machining accuracy, careful attention must be given to the tool’s movement, and the tool-setting method must meet the accuracy requirements of the part being processed. When handling high-precision parts, using a dial indicator can help accurately find the tool path, though this method is relatively inefficient. To improve machining efficiency and accuracy, some factories have begun adopting new technologies such as optical and electronic instruments to reduce processing time and enhance overall machining quality.

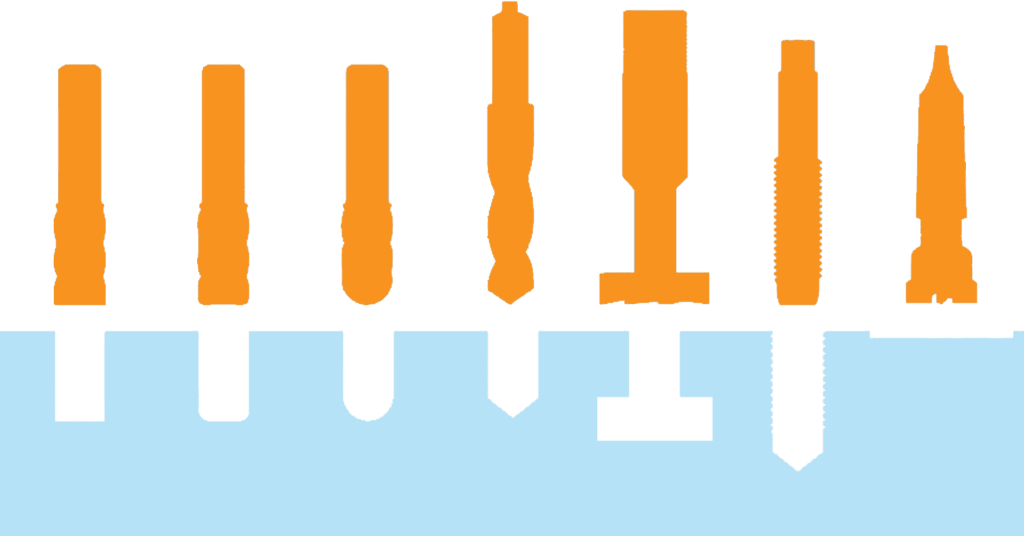

Types And Characteristics Of Commonly Used Tools For CNC Machining

Choosing the right tool for CNC machining depends on the specific operation, material, and desired outcome. Understanding the types and characteristics of commonly used tools is essential for optimizing machining processes, improving efficiency, and ensuring high-quality results.

End Mills:

- Versatile with multiple cutting edges.

- Available in various shapes (flat, ball, chamfer).

- Can be used for both roughing and finishing operations.

Mainly used for milling, contouring, slotting, and drilling.

Drills:

- Typically have a pointed tip for initiating holes.

- Available in various diameters and lengths.

- Can be straight or tapered.

Mainly used for drilling holes in various materials, often used in combination with reamers for finishing.

Reamers:

- Designed to enlarge and improve the accuracy of existing holes.

- Typically have a smooth finish and tighter tolerances.

Used after drilling to achieve precise hole dimensions and smooth finishes.

Taps:

- Used for cutting internal threads in holes.

- Available in various sizes and thread types (metric, imperial).

Essential for creating threaded holes for screws or bolts.

- Large diameter tools with multiple inserts.

- Designed for face milling operations, providing a flat surface finish.

Used for machining flat surfaces and achieving high material removal rates.

Ball Nose End Mills:

- Rounded cutting edge, ideal for complex shapes and contours.

- Good for 3D machining and finishing applications.

Often used in mold making, die making, and sculpting.

CNC Lathe Tools:

- Includes various types such as turning tools, parting tools, and grooving tools.

- Designed specifically for turning operations on a CNC lathe.

Used for shaping cylindrical parts, creating threads, and parting off.

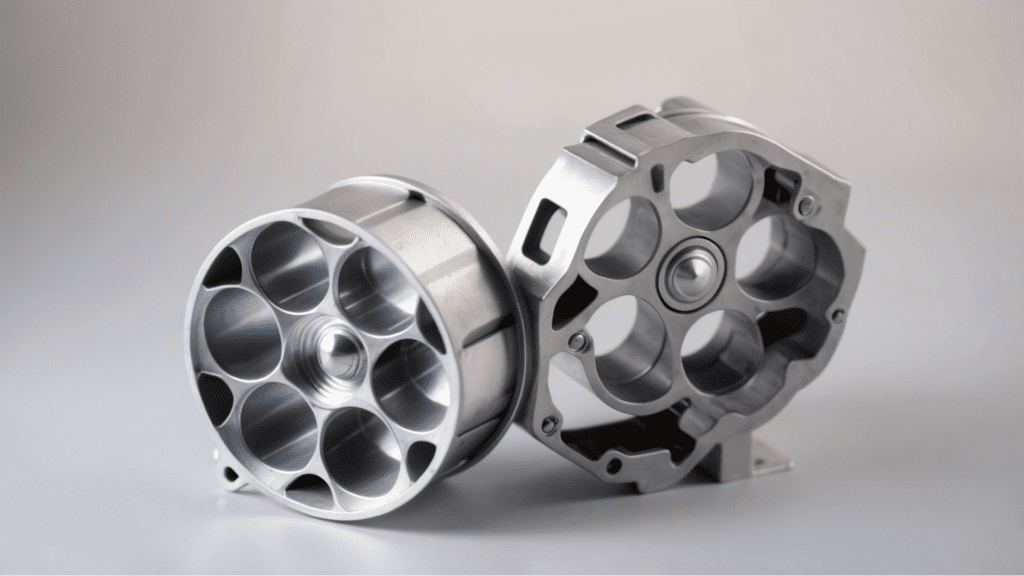

Boring Bars:

- Used for enlarging existing holes with high precision.

- Can be adjusted for different diameters.

Commonly used in CNC machining for achieving tight tolerances.

Insert Tools:

- Tools that use replaceable cutting inserts.

- Economical and versatile, allowing for quick changes.

Suitable for various machining operations, including turning, milling, and drilling.

Specialty Tools:

- Customized tools designed for specific applications or geometries.

- Can include profile tools, contour tools, or tools with unique features.

Used for specialized tasks that standard tools cannot perform efficiently.

Conclusion

Effective tool selection and setting are critical components of the CNC machining process that directly influence efficiency, precision, and product quality. By carefully considering factors such as material compatibility, tool geometry, cutting conditions, and application requirements, manufacturers can optimize their operations and achieve superior results. Additionally, maintaining a systematic approach to tool setting ensures that machines operate smoothly, reducing the risk of errors and enhancing tool life. As industries continue to evolve, staying informed about advancements in tool technology and best practices will empower CNC operators to meet the challenges of modern machining with confidence.

Final Thoughts

As a professional with 15 years of experience in CNC machining services, I understand the critical importance of tool selection and setting. The right tools not only enhance machining precision but also significantly improve efficiency. In a recent aerospace component project, we chose carbide tools specifically designed for aluminum alloys, which successfully reduced cutting forces and improved surface finish. This choice allowed us to complete the project ahead of schedule while minimizing tool wear. If you’re looking for a partner that offers precise and efficient machining services, I highly recommend Ultirapid. We have the expertise and knowledge to meet all your CNC machining needs.

Faqs

How To Select CNC Tools?

To select CNC tools, first consider the material compatibility to ensure the tool is suitable for the workpiece material, such as metal or plastic. Next, match the tool to the specific machining operation, whether it be milling, turning, or drilling, to guarantee effectiveness. Evaluate the cutting parameters, including cutting speed, feed rate, and depth of cut, to choose tools that can perform well under those conditions. Additionally, pay attention to the tool geometry, selecting shapes and cutting edges that align with the desired finish and precision. It’s also important to opt for tools that offer durability and longevity, minimizing the need for replacements. Finally, balance initial costs with performance and ensure that the tools are readily available and compatible with your existing CNC machines.

What is A CNC Tool Setter?

A CNC tool setter is a device used to accurately measure and set the position of cutting tools on a CNC machine. It ensures that the tool height and offset are correctly established, allowing for precise machining operations. Tool setters can improve efficiency by reducing setup time and minimizing errors during the machining process. They often come in various types, including mechanical, electronic, and optical models, to suit different machining needs.