In the relentless pursuit of efficiency and innovation, CNC machining has emerged as a game-changer in manufacturing. By automating the cutting, shaping, and finishing of materials, it unlocks new levels of productivity and opens doors to designs previously deemed impossible.But do you know how it works? This article explains in depth the working principle behind this technology. Let’s read on.

Basic Concepts Of CNC Machining

What is CNC machining?Computer Numerical Control (CNC) machining is a manufacturing process where computerized controls and machine tools remove layers of material from a workpiece to produce custom-designed parts. At its core, CNC machining utilizes pre-programmed software and code to dictate the movement of factory tools and machinery. This control allows for precision, consistency, and complexity that manual machining cannot achieve.

Central to CNC machining is the translation of design information from Computer-Aided Design (CAD) software into numerical data that the machines can interpret. This data dictates the cutting paths and tooling operations, enabling the machine to produce intricate parts with high accuracy. The use of G-code and M-code in programming provides specific instructions on movements, speeds, tooling, and other operational parameters.

Automation is a fundamental concept in CNC machining, reducing the need for manual intervention and minimizing human error. Machines can operate continuously once programmed, leading to increased efficiency and throughput. This automation also allows for repeatability in production, ensuring that each part produced meets the exact specifications required. CNC machining has thus become essential in modern manufacturing, offering a combination of precision and efficiency that forms the backbone of mass production in various industries.

What Are The Components Of CNC Machining System?

A CNC (Computer Numerical Control) machining system is a complex assembly of various components that work together to automate the manufacturing process. Each component plays a crucial role in ensuring precision, efficiency, and reliability in the production of parts. The CNC Control Unit serves as the “brain” of the CNC machining system, interpreting programmed instructions and directing machine actions. It includes input devices like keyboards, mice, or code readers used to load programs and commands. The processor, or CNC controller, decodes these instructions and sends signals to the machine tool. Output devices then transmit signals to control the machine’s motors, actuators, and other components.

The Machine Tool is the physical apparatus that performs the machining operations. Examples include lathes for turning cylindrical parts, milling machines for creating complex shapes, drilling machines for producing holes, grinding machines for precision finishing, and specialized machines like EDM (Electrical Discharge Machining), laser cutters, and waterjet cutters. The Drive System provides power and motion control, typically comprising motors—often precise and controllable servo motors—and amplifiers that boost signals from the CNC control unit. The Transmission System converts the motors’ rotary motion into linear motion along the machine axes, using components like ball screws for precise movement, lead screws as a simpler option, or rack and pinion systems for longer travel distances. The Mechanical Structure, consisting of a rigid frame and supporting components, ensures stability and accuracy during operation.

Auxiliary Equipment supports the machining process. The tooling system holds and positions cutting tools using tool holders, collets, and automatic tool changers (ATCs). The cooling system lubricates and cools the cutting zone to extend tool life and improve surface finish, employing coolants, air blasts, or through-tool coolant delivery. Chip removal systems, such as conveyors, augers, or vacuum systems, remove chips or swarf generated during machining to prevent interference and enhance safety. Workholding devices like vises, clamps, and fixtures securely hold the workpiece in place. Lastly, the inspection system measures and verifies the accuracy of machined parts, either integrated into the machine or as separate equipment, using probes, lasers, or other metrology tools.

What Is The Working Principle Of CNC Machining?

The working principle of CNC machining revolves around the automated control of machine tools through pre-programmed instructions.CNC machining, driven by pre-programmed software, automates the control of factory tools and machinery, enabling precise and complex part production. The process begins with a CAD model, a detailed 2D or 3D representation of the desired part, containing all necessary geometrical and dimensional information. This digital blueprint is then translated into a CNC program using CAM software. This involves planning the machining operations, selecting tools, defining toolpaths, and setting cutting parameters like feed rate and spindle speed. The CAM software then generates G-code and M-code, the language understood by the CNC machine.

Before machining begins, the machine is set up. Appropriate cutting tools are installed, the workpiece is securely clamped, and the machine’s zero point is calibrated. The CNC program is then loaded into the control unit via various methods, and a simulation or dry run may be performed to verify the program and prevent errors. The CNC control unit then takes over, reading and interpreting the program line by line, sending commands to the drive system to move the tools and workpiece.

The machine executes the programmed movements along its axes, with the control unit calculating intermediate points for smooth and precise toolpaths. Cutting tools engage the workpiece, removing material through operations like milling, turning, drilling, or grinding. Cutting parameters are precisely controlled to optimize tool life and surface finish. Crucially, feedback systems employing sensors and encoders provide real-time data, allowing for closed-loop control. The control unit continuously adjusts movements based on this feedback, maintaining accuracy and correcting any deviations.

Finally, after the program completes, the finished part is unloaded and inspected for quality. Secondary operations like deburring or polishing might be necessary. CNC machining’s strength lies in its automation, precision, and programmability. This allows for high efficiency, consistent results, minimal waste, and the ability to create highly complex parts. It has become a cornerstone of modern manufacturing, bridging the gap between digital design and physical product.

G-Code Vs M-Code

G-code and M-code are the two main programming languages used in CNC machining. They work together to control the machine’s movements and actions, but they serve distinct purposes.

G-Code (Preparatory Codes)

These codes primarily control the geometry of the machining process. They tell the machine where to move and how to move.

Movement Commands: Specify the movement of the machine’s axes (X, Y, Z) to specific coordinates. This includes linear movements (G01), rapid traverses (G00), and circular interpolation (G02/G03).

Coordinate System: Define the coordinate system used for positioning (G54-G59).

Plane Selection: Select the working plane (G17-G19) for operations like milling.

Units: Set the units for measurements (G20 for inches, G21 for millimeters).

Canned Cycles: Define pre-programmed routines for common machining operations like drilling or pocketing.

M-Code (Miscellaneous Codes)

These codes control machine functions that are not related to movement. They tell the machine what to do.

Spindle Control: Start (M03), stop (M05), and control the speed (M04) of the spindle.

Coolant Control: Turn coolant on (M08) and off (M09).

Tool Changes: Initiate automatic tool changes (M06).

Program Control: Stop the program (M00), optional stop (M01), end the program (M30), and rewind the program (M02).

Other Functions: Control a variety of other machine-specific functions, such as pallet changes or activating auxiliary equipment.

Key Differences Summarized:

| Feature | G-Code | M-Code |

| Primary Role | Geometric control (movement) | Machine function control (actions) |

| Examples | G00, G01, G02, G03, G20, G21, G90 | M03, M05, M06, M08, M09, M30 |

| Focus | Positioning, toolpaths, interpolation | Spindle, coolant, tools, program flow |

G-code and M-code work in tandem within a CNC program. G-codes define the tool’s path, while M-codes control the supporting functions necessary for the machining process. For example, a program might use G01 to move the tool to a specific location, then M03 to start the spindle and begin cutting. The coordinated execution of these codes enables the automated and precise fabrication of parts.

Working Principles Of Different CNC Machine Tools

While all CNC machines share the fundamental principle of computer-controlled movement, different machine tools are designed for specific machining operations.

CNC Milling Machine: A rotating cutting tool removes material from a stationary or moving workpiece. The tool can move along multiple axes (X, Y, Z, and sometimes additional rotational axes) to create complex shapes and features.

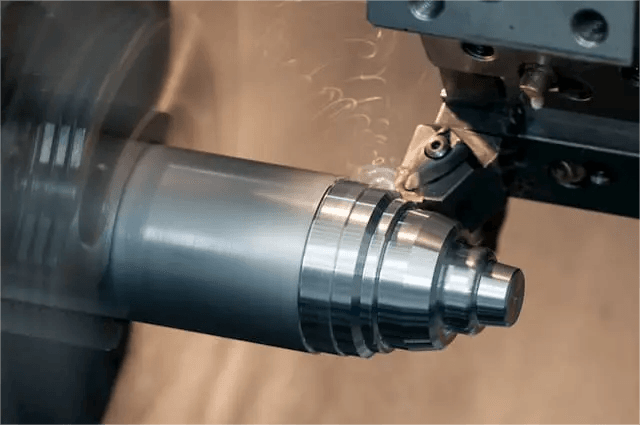

CNC Lathe: A rotating workpiece is shaped by a stationary or moving cutting tool. The tool typically moves along two axes (X and Z) to create cylindrical or conical shapes.

CNC Drilling Machine: A rotating drill bit creates holes in a stationary workpiece. The machine primarily controls the Z-axis movement for drilling depth.

CNC Grinding Machine: An abrasive grinding wheel removes material from a workpiece to achieve a precise surface finish.

CNC Router: Similar to a milling machine, a CNC router uses a rotating cutting tool to remove material from a workpiece, often sheet materials like wood, plastic, or composites.

CNC Electrical Discharge Machining (EDM): Material is removed by a series of electrical sparks between an electrode and the workpiece, typically in a dielectric fluid.

CNC Laser Cutting Machine: A high-powered laser beam cuts or engraves materials by melting, burning, or vaporizing them.

CNC Waterjet Cutting Machine: A high-pressure jet of water, often mixed with an abrasive substance, cuts through materials.

Each machine is designed for specific applications and materials, but they all share the common principle of using computer control to achieve precise and automated machining.

Conclusion

As an important equipment in modern manufacturing industry, the working principle of CNC machine tools involves many aspects of knowledge and technology. By continuously optimizing process design principles, improving tool use efficiency, mastering programming skills, and realizing process standardization, the processing efficiency and quality of CNC machine tools can be significantly improved. With the continuous development of technology, CNC machine tools will play an important role in a wider range of fields in the future.

Contact DONGGUAN KESU HARDWARE CO., LTD. if you want the best in CNC manufacturing.

Final Thoughts

As a professional with 15 years of experience in CNC machining service, I’ve witnessed the industry’s transformation from manual operations to highly automated, precision-based manufacturing. CNC machines operate by following precise computer-controlled instructions, guiding cutting tools to efficiently shape materials, ensuring consistency and accuracy for complex parts. The key advantages lie in its repeatability and high production efficiency, making it indispensable in high-demand sectors like aerospace. Ultirapid, with its advanced technology and excellent customer support, stands out as a reliable partner in this field, meeting the growing needs for precision machining.

Faqs

How Does CNC Operate?

The operation of CNC (computer numerical control) machine tools is mainly achieved through programming.The operator or process personnel compiles a reasonable CNC processing program based on these factors, and then inputs the program into the CNC system. The CNC system will interpret these program codes and generate executable machine codes to control the moving parts and tools of the machine tool to perform processing according to the predetermined trajectory. During the processing process, the CNC system can also automatically generate CNC codes according to the processing task indicator, and complete the idle operation and trial cutting of the processing process.

What Is The Function Of CNC Machining?

The function of CNC machining is to utilize computer numerical control technology to automatically control machine tools for high-precision and high-efficiency machining of workpieces. It precisely controls the relative movements between cutting tools and workpieces according to pre-programmed instructions, enabling the manufacture of complex shapes and precise components. Through CNC machining, production efficiency and product quality are improved, manual intervention and human errors are reduced, and it meets the demands of modern manufacturing for complex and diversified products.

What Are The Principal Machining Processes?

The principal machining processes include milling, turning, drilling, grinding, and various other specialized techniques like electrical discharge machining (EDM) and laser cutting.

What Is A CNC Process?

A CNC process is a subtractive manufacturing method that uses computer-controlled tools to remove material from a workpiece, creating a desired shape or feature.

What Are The Basic Steps In CNC Machining?

The basic steps in CNC machining are designing the part (CAD), generating the toolpath (CAM), setting up the machine and workpiece, loading the CNC program, executing the machining operation, and inspecting the finished part.