Have you ever wondered how those perfectly shaped components in machines and everyday products are made? CNC turning plays a crucial role in this process, transforming raw materials into precision parts used across various industries. In this article, we’ll explore the ins and outs of CNC turning tools—what they are, their types, advantages, disadvantages, and performance factors. So, let’s dive in and uncover the essentials together!

What Is CNC Turning Tools?

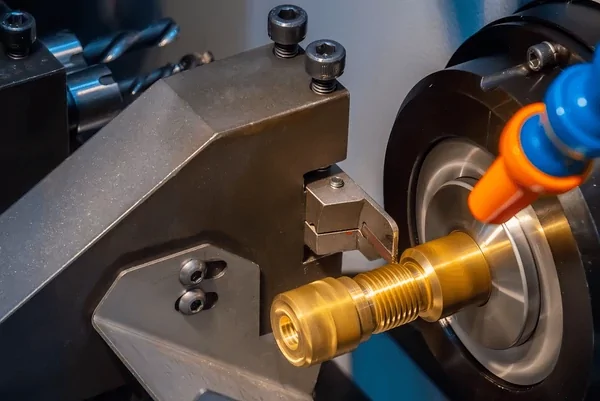

CNC turning tools are specialized cutting tools used in CNC turning machines, primarily for shaping workpieces (usually metals) by removing excess material. These tools include several key components. First, turning inserts are small, replaceable cutting edges that attach to a tool holder, available in various geometries and coatings to optimize performance for different materials and cutting conditions. Second, tool holders securely hold the inserts in place and can be adjusted for cutting depth, typically made from durable materials to withstand machining stresses.

Additionally, live tools in CNC lathes can rotate independently, allowing for milling operations alongside turning, which is useful for creating complex geometries. Boring bars are used to enlarge existing holes and achieve precise internal diameters, while parting tools are designed to cut finished parts from the main workpiece, usually with a flat, wedge-shaped design. Grooving tools are used to create grooves or channels in the material, and threading tools are specifically designed for producing internal or external threads.

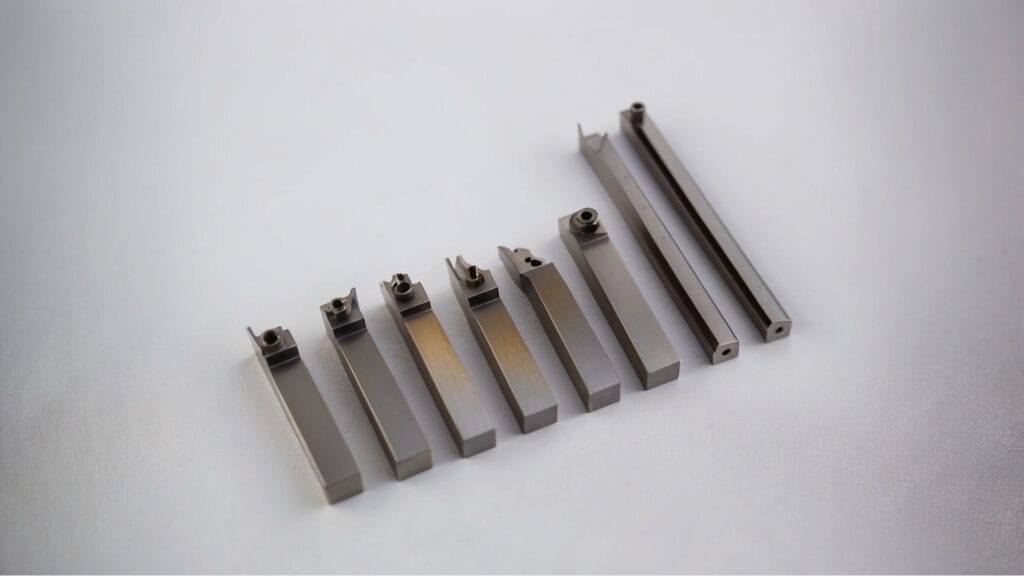

Main Types Of CNC Turning Tools

CNC turning tools come in various types, each designed for specific functions. You might be surprised to learn that each tool has its own unique purpose. Let’s take a closer look at these tools to see how they contribute to the CNC turning process!

- Turning Tools: Primarily used for shaping the outer diameter of a workpiece. They come in various geometries, including flat and round, allowing for different cutting profiles and applications.

- Drill Bits: Designed for creating holes in the workpiece, drill bits can vary in size and type (such as twist or spade bits) to accommodate different materials and hole specifications.

- Milling Cutters: While typically associated with milling operations, some CNC turning machines can utilize milling cutters for specific tasks, such as creating complex shapes or grooves on the workpiece.

- Boring Tools: These tools are used to enlarge existing holes or create precise internal cylindrical surfaces. Boring tools provide high accuracy and are essential for achieving tight tolerances.

- Threading Tools: Specifically designed for cutting threads on the exterior or interior surfaces of a workpiece, these tools ensure that threaded components meet precise specifications for functionality.

What Are The Advantages Of CNC Turning Tools?

CNC turning tools offer numerous benefits that make them a preferred choice in manufacturing. Are you ready to discover why so many industries rely on these tools? Let’s explore their key advantages!

High Precision

CNC turning tools are engineered to deliver exceptional accuracy, enabling the production of components with intricate designs and tight tolerances. The computerized control systems ensure consistent cutting paths, which minimizes errors and enhances the overall dimensional accuracy of parts. This level of precision is critical in industries such as aerospace and medical devices, where even minor deviations can lead to significant issues.

High Efficiency

The automation of CNC turning processes significantly increases production speeds compared to traditional machining methods. These tools can operate continuously with minimal downtime, allowing for faster cycle times and higher output. Additionally, CNC systems optimize cutting parameters in real-time, further enhancing efficiency and reducing waste, which translates to cost savings for manufacturers.

Reliability

CNC turning tools are built for durability and consistent performance. The automation of machining processes reduces human error, leading to fewer defects and rework. This reliability ensures that production runs are predictable and that quality standards are consistently met, making it easier for companies to maintain their reputations and meet customer demands.

Flexibility

One of the standout features of CNC turning is its adaptability. These machines can be easily reprogrammed to accommodate different part designs and production runs, making them ideal for both mass production and custom projects. This flexibility allows manufacturers to respond quickly to market changes, fulfill varying customer requirements, and efficiently manage a diverse product portfolio without significant setup times.

What Are The Disadvantages Of CNC Turning Tools?

While CNC turning tools have many advantages, they also come with some drawbacks. It’s important to be aware of these as you consider your options. Let’s take a look at a few limitations!

High Cost

CNC turning tools often come with a significant initial investment. The cost of the machines themselves can be substantial, along with the necessary software and training for operators. For smaller businesses, this high entry cost can be prohibitive. Additionally, ongoing expenses, such as maintenance, tooling, and operational costs, can further strain budgets. It is crucial for companies to carefully evaluate their return on investment (ROI) to justify these expenses.

Complex Operation

Operating CNC turning machines requires specialized knowledge and skills. While automation reduces the need for manual labor, it also necessitates trained personnel who can program and manage the machines effectively. Understanding complex software, interpreting G-code, and troubleshooting issues can be a barrier for some operators. If staff training is inadequate, it can lead to potential delays in production, resulting in lost time and increased costs.

Difficult Maintenance

CNC turning tools require regular maintenance to ensure optimal performance and longevity. However, diagnosing and fixing issues can be challenging due to the intricate nature of these machines. Specialized technicians may be needed for repairs, and sourcing spare parts can sometimes lead to longer downtimes. This downtime not only impacts overall production efficiency but can also increase costs, as production delays may result in unmet customer demands and potential loss of business.

Basic Functions Of CNC Turning Tools

Now that we’ve discussed advantages and disadvantages, let’s get into the heart of CNC turning tools: their functions! Understanding what these tools can do is essential for maximizing their benefits. Ready to learn more?

Cutting:The primary function of CNC turning tools is cutting, which involves removing material from the workpiece to create desired shapes and dimensions. The CNC system controls the tool’s movement along predetermined paths, ensuring precise cuts that meet specific tolerances. This capability allows for the production of complex geometries and fine finishes essential in many industries.

Shaping:CNC turning tools are adept at shaping the workpiece into various forms, including cylindrical, conical, and spherical profiles. By adjusting the cutting parameters and tool path, operators can create intricate designs and profiles that are difficult to achieve with manual machining. This shaping capability enhances design flexibility and expands the range of components that can be produced.

Facing:Facing is a crucial function of CNC turning tools, where the tool is used to create a flat surface on the end of the workpiece. This operation is essential for ensuring proper fitment and assembly of components. CNC machines can achieve a high degree of flatness and smoothness, which is critical in applications requiring tight tolerances and accurate mating surfaces.

Drilling:Although primarily associated with turning, CNC machines can also perform drilling operations. This involves creating holes in the workpiece, either through the use of specialized drilling tools or by employing the lathe’s cutting tools. The ability to drill accurately and efficiently in conjunction with turning operations streamlines the manufacturing process, reducing the need for multiple setups and enhancing overall productivity.

What Factors Affect The Performance Of CNC Tools?

Several factors influence the effectiveness of CNC tools. Have you ever considered what might affect their performance?

Tool Material:The material from which CNC tools are made significantly impacts their performance. Common materials include high-speed steel (HSS), carbide, and ceramic. Carbide tools, for example, offer higher hardness and wear resistance, making them suitable for machining harder materials and maintaining cutting edges for longer periods. The choice of tool material also affects the tool’s ability to withstand heat generated during machining, influencing overall cutting efficiency.

Geometry:The geometry of CNC tools, including factors such as cutting edge angles, tool shape, and flute design, plays a crucial role in their performance. Well-designed geometry can enhance cutting efficiency, reduce cutting forces, and improve chip removal. For instance, a sharp cutting edge reduces friction and wear, leading to smoother cuts and better surface finishes. Optimizing tool geometry for specific machining tasks can result in significant gains in productivity and tool life.

Cutting Speed:Cutting speed, defined as the speed at which the cutting tool engages the material, is a critical factor in CNC machining. Higher cutting speeds can lead to increased productivity but may also generate excessive heat, risking tool wear or damage. Conversely, lower cutting speeds can prolong tool life but may reduce production efficiency. Finding the optimal cutting speed for a specific material and tool combination is essential for maximizing performance while ensuring quality.

Feed Rate:The feed rate refers to the distance the tool advances during each revolution of the workpiece. An appropriate feed rate is vital for achieving the desired surface finish and dimensional accuracy. Too high a feed rate can lead to tool wear, poor surface quality, and potential tool failure, while too low a feed rate may result in inefficient machining and longer cycle times. Balancing the feed rate with other parameters is essential for effective machining.

Coolant Usage:The use of coolant during CNC machining significantly influences tool performance and longevity. Coolants help reduce friction and dissipate heat generated during the cutting process, preventing tool overheating and wear. They also assist in chip removal, which can otherwise obstruct cutting paths and affect the quality of the workpiece. Selecting the right coolant type and application method can enhance machining efficiency and improve overall tool life.

Conclusion

CNC turning tools are essential in modern manufacturing, offering high precision and efficiency. By understanding their types, advantages, disadvantages, basic functions, and performance factors, manufacturers can optimize their operations and maintain a competitive edge in today’s fast-paced market. Embracing CNC turning technology not only enhances production capabilities but also opens up new possibilities in design and functionality.

In summary, we can see that CNC Turning is a highly efficient machining technology that uses computer numerical control systems to control lathe movements, achieving precise material processing. CNC Turning tools have advantages such as high precision, high efficiency, reliability, and flexibility, but also have disadvantages such as high cost, complex operation, and difficult maintenance. Understanding the basic functions of CNC Turning tools and the factors affecting their performance can help us better use and maintain CNC tools.

Final Thoughts

CNC turning tools play a pivotal role in modern machining processes, offering precision and efficiency that are critical for high-quality production. With 15 years of experience in the CNC machining service industry, I have witnessed the significant advantages these tools bring. For example, at Ultirapid, we have utilized high-quality carbide tools that have markedly improved our production output while minimizing downtime.

However, it is essential to acknowledge the drawbacks, including the high costs and complexity of maintenance associated with CNC turning tools. At Ultirapid, we address these challenges by investing in advanced tooling and providing comprehensive training for our team, ensuring we maintain optimal performance and quality.

The selection of the right CNC turning tools is vital for enhancing production capabilities. I recommend considering Ultirapid for your machining needs, where our expertise and state-of-the-art technology can help you achieve your production goals efficiently.

Faqs

What Are CNC Turning Tools, And How Do They Differ From Traditional Tools?

CNC turning tools are automated cutting tools used in CNC lathes to shape materials by removing material from a rotating workpiece. They differ from traditional tools in that CNC tools are controlled by computer programs, allowing for higher precision, repeatability, and the ability to produce complex geometries, while traditional tools often rely on manual operation and settings.

What Types Of Materials Can Be Machined Using CNC Turning Tools?

CNC turning tools can machine a variety of materials, including metals such as aluminum, steel, brass, and titanium, as well as plastics, composites, and some ceramics, depending on the tool specifications and machining requirements.

How Do CNC Lathe Tools Differ From General Lathe Tools?

CNC lathe tools are automated and controlled by computer programs, allowing for precise and repeatable machining, while general lathe tools are typically operated manually, requiring the machinist to set parameters and control movements directly.