Cast impellers are vital components in pumps, fans, and compressors, directly impacting equipment efficiency and durability. This article provides an in-depth analysis of the impeller casting process, covering material selection, casting techniques, machining, and quality control, unlocking the secrets of precision impeller manufacturing.

Overview Of The Cast Impeller Manufacturing Process

The production of cast impellers involves multiple complex steps, from raw material to finished product, requiring scientific design and precise machining. This section details the cast impeller manufacturing process and compares it with traditional forging, highlighting its cost and performance advantages.

Cast Impeller Manufacturing Process

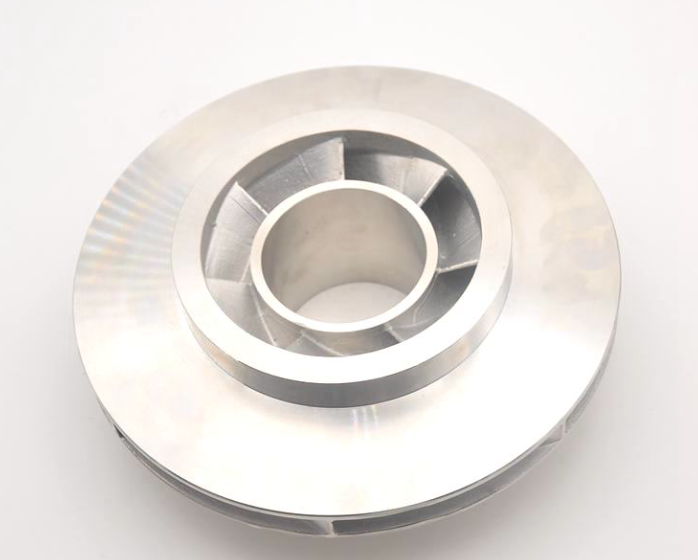

The typical process for cast impellers includes mold design → casting → rough machining → precision machining → dynamic balancing → surface treatment.

- Mold Design: Create sand, metal, or lost-foam molds based on impeller geometry for casting accuracy.

- Casting: Pour molten metal into the mold to form the impeller blank.

- Rough Machining: Remove excess material via turning or milling to achieve preliminary shape.

- Precision Machining: Use five-axis CNC machines to refine flow passages for optimal dimensions and surface finish.

- Dynamic Balancing: Correct imbalances per ISO 1940 standards to minimize operational vibration.

- Surface Treatment: Apply polishing or coatings to enhance corrosion resistance and fluid efficiency.

Comparison with Forged Impellers

| Feature | Cast Impeller | Forged Impeller |

| Cost | Lower, suitable for small/medium batches | Higher, due to mold and processing costs |

| Performance | Ideal for complex shapes, slightly lower strength | Superior mechanical strength for high-stress applications |

| Applications | Pumps, fans, compressors | Aerospace, high-pressure equipment |

| Production Cycle | Shorter, flexible mold design | Longer, requires multiple forging and heat treatment steps |

Cast impellers are preferred for cost-effectiveness and adaptability in small to medium-scale production, while forged impellers excel in high-strength, high-reliability applications.

Five Common Materials For Cast Impellers And Selection Criteria

Material choice significantly impacts impeller performance and lifespan. This section explores five common materials, their properties, and selection criteria to help you choose the best material for specific operating conditions.

Cast Iron Impeller (HT250, QT400)

Features: Low cost, good castability, moderate strength, and wear resistance.

Applications: Water pumps, general-purpose fans in low-corrosion environments.

Selection Criteria: Ideal for budget-conscious projects with minimal corrosion requirements.

Stainless Steel Impeller (304, 316L)

Features: High corrosion resistance, smooth surface, suitable for harsh environments.

Applications: Food processing, chemical pumps, wastewater treatment.

Selection Criteria: Preferred for acid/alkali resistance or hygiene-compliant applications.

Aluminum Alloy Impeller

Features: Low density, lightweight, good thermal conductivity, moderate corrosion resistance.

Applications: Low-density fluid systems like ventilation or small pumps.

Selection Criteria: Best for lightweight designs or low-pressure fluid transfer.

Copper Alloy Impeller (Bronze, Brass)

Features: Excellent seawater corrosion resistance, good wear resistance, and machinability.

Applications: Marine engineering, ship pumps.

Selection Criteria: Optimal for seawater or high-salinity environments.

High-Temperature Alloy Impeller (Inconel)

Features: High-temperature and corrosion resistance, excellent mechanical properties for extreme conditions.

Applications: Aero-engines, gas turbines, energy equipment.

Selection Criteria: Essential for high-temperature, high-pressure, or corrosive applications.

Choose materials based on fluid properties (corrosiveness, temperature), operating pressure, and budget. For example, 316L stainless steel suits chemical industries, while Inconel is ideal for aerospace.

Comparison Of Four Mainstream Impeller Casting Techniques

The choice of casting technique directly affects impeller quality, cost, and production efficiency. This section compares sand casting, precision casting, metal mold casting, and lost-foam casting to guide optimal process selection.

| Technique | Advantages | Disadvantages | Applications |

| Sand Casting | Low cost, highly adaptable | Lower precision, rough surface | Single-piece/small-batch production |

| Precision Casting | High precision, complex shapes | Higher cost, longer cycle | High-precision complex impellers |

| Metal Mold Casting | Smooth surface, high-volume production | High mold cost, shape limitations | Mass-produced standardized impellers |

| Lost-Foam Casting | Reduced machining allowance, eco-friendly | Complex process, high mold requirements | Medium/small-batch complex impellers |

Sand Casting

- Features: Uses sand molds, low mold cost, suitable for single or small-batch production.

- Applications: Large, simple-structured impellers, e.g., water pump impellers.

Precision Casting (Investment Casting)

- Features: Uses wax patterns and ceramic shells for high precision and smooth surfaces.

- Applications: Complex, high-precision impellers, e.g., aero-engine impellers.

Metal Mold Casting (Die Casting)

- Features: Reusable metal molds, high efficiency, ideal for mass production.

- Applications: Standardized impellers, e.g., automotive water pump impellers.

Lost-Foam Casting

- Features: Uses foam patterns, reduces machining allowance, environmentally friendly.

- Applications: Medium/small-batch production of complex impellers.

Detailed Analysis Of Core Impeller Machining Processes

The machining processes for cast impellers directly determine their performance and durability. This section examines rough machining, precision machining, dynamic balancing, and surface treatment, revealing how to produce high-performance impellers.

Rough Machining

Rough machining is the initial stage of impeller processing, aimed at removing excess material to form the basic shape. This is typically done using standard CNC lathes or vertical milling machines. During this step, controlling the cutting speed is crucial to prevent stress concentrations within the material, which could lead to structural weaknesses later in the process. The focus is on shaping without compromising the integrity of the impeller.

Flow Passage Precision Machining

Once the basic shape is formed, flow passage precision machining is performed using advanced five-axis CNC machines, such as those manufactured by DMG MORI or Mazak. This stage is essential for refining the internal flow passages of the impeller to optimize fluid dynamics and efficiency. The process requires tight tolerances, typically ±0.05 mm, and a high surface finish quality with roughness values of Ra ≤ 1.6 μm. Precision at this stage directly impacts the impeller’s hydraulic performance.

Dynamic Balancing

After machining, dynamic balancing is conducted to ensure the impeller rotates smoothly without causing vibrations. Balancing machines are used to detect any mass imbalances, following standards such as ISO 1940. Depending on the application, different balance grades are targeted—G6.3 for general industrial equipment and G2.5 for high-precision systems. Corrections are made by drilling material from specific locations or adding counterweights to restore balance and operational stability.

Surface Treatment

The final step involves surface treatment, which may include polishing, sandblasting, or applying specialized coatings like ceramic or PTFE. This process serves multiple purposes: improving surface smoothness, enhancing corrosion resistance, and extending the impeller’s service life. The choice of treatment depends on the application environment and performance requirements, ensuring the impeller can withstand wear, chemical exposure, and prolonged use.

Five Critical Quality Control Points In Impeller Machining

Quality control is the cornerstone of cast impeller manufacturing, ensuring performance and reliability. This section details control methods for dimensional accuracy, defect detection, dynamic balancing, surface roughness, and material properties.

Dimensional Accuracy Control

To ensure optimal performance and assembly compatibility, dimensional accuracy is tightly controlled during impeller manufacturing. Industry standards typically allow a general tolerance of ±0.05 mm, while more complex internal flow passages require a stricter tolerance of ±0.02 mm. Coordinate measuring machines (CMMs) are employed to perform precise inspections on critical dimensions, ensuring that components meet design specifications and maintain aerodynamic or hydraulic efficiency.

Porosity And Sand Inclusion Detection

Internal defects such as porosity or sand inclusions can significantly weaken the impeller and compromise its performance. Non-destructive testing methods, including X-ray and ultrasonic inspection, are used to detect these flaws. The standard threshold for acceptability is that no pores or inclusions exceed 0.5 mm in diameter. Identifying and addressing such defects early ensures structural integrity and prolongs the impeller’s lifespan under stress.

Dynamic Balancing Grades

Dynamic balancing is crucial for reducing vibration and ensuring stable operation at high rotational speeds. The ISO 1940 standard categorizes balance quality into different grades—G6.3 for standard industrial pumps and G2.5 for high-speed applications such as fans or precision machinery. Balancing machines from manufacturers like Schenck or Hofmann are used to measure and adjust mass distribution, typically by drilling or adding counterweights.

Surface Roughness Requirements

Surface roughness has a direct impact on fluid efficiency and wear resistance. For impellers, the internal flow passages must achieve a roughness of Ra ≤ 1.6 μm, while the outer surfaces should be no rougher than Ra ≤ 3.2 μm. Failing to meet these standards can reduce fluid efficiency by 5% to 10%, due to increased turbulence and friction. Achieving the right finish is therefore essential for both performance and energy efficiency.

Material Mechanical Property Testing

To validate the mechanical strength and durability of impeller materials, mechanical property testing is conducted. Key tests include tensile strength, hardness, and ductility evaluations. These are typically performed using tensile testing machines and Brinell hardness testers. Ensuring materials meet required mechanical standards helps prevent failure under pressure, heat, or corrosive conditions, especially in critical applications.

Common Issues In Impeller Machining And Solutions

Casting and machining impellers often encounter defects or deformation, affecting quality. This section analyzes three common issues and their solutions to optimize production and improve yield rates.

Casting Defects (Shrinkage, Cracks)

Causes: Shrinkage and cracks often arise from uneven cooling rates, improper mold filling, or inadequate mold design. Shrinkage cavities form when there’s insufficient molten metal to compensate for volume reduction during solidification. Cracks may occur due to thermal stress concentration, especially in sharp corners or thick cross-sections.

Solutions: To reduce shrinkage, gating and riser systems should be optimized to ensure a smooth and continuous flow of molten metal. The use of chills—metal inserts that absorb heat rapidly—helps promote directional solidification and reduce internal voids. Proper mold preheating and controlled cooling rates further minimize thermal stress and cracking. Simulations (e.g., CFD, solidification modeling) can assist in refining mold design.

Machining Deformation

Causes: Deformation during or after machining can be caused by residual stress in the cast part, incorrect clamping methods, or aggressive cutting parameters. Internal stresses are often locked into the material during casting or heat treatment and may be released unevenly when material is removed.

Solutions: Performing stress-relief annealing before machining helps release internal tensions uniformly. Fixtures should be designed to provide stable and balanced support without over-constraining the part, reducing the risk of warping. Machining in multiple light passes instead of heavy cuts, especially on thin or complex sections, can also reduce distortion. Precision CNC programs should be used to control tool paths and minimize heat buildup.

Excessive Imbalance

Causes: Imbalance results from asymmetrical mass distribution due to casting irregularities, uneven machining, or material density variation. Even minor inconsistencies in vane thickness or hub geometry can shift the center of mass, leading to vibrations at high rotational speeds.

Solutions: Use dynamic balancing machines to detect imbalance accurately—typically following ISO 1940 standards. Corrections involve drilling small material amounts from heavier areas or adding calibrated counterweights to lighter sections. If imbalances are caused by machining errors, selective re-machining may be required. Maintaining tight tolerances in casting and consistent toolpaths during machining helps prevent imbalance from the outset.

Conclusion

Selecting a reliable cast impeller machining service requires evaluating the supplier’s expertise, equipment, and quality control capabilities. Prioritize providers with precision casting experience, advanced testing equipment, and simulation design capabilities to ensure impeller performance and longevity.