What is a CNC Machine?

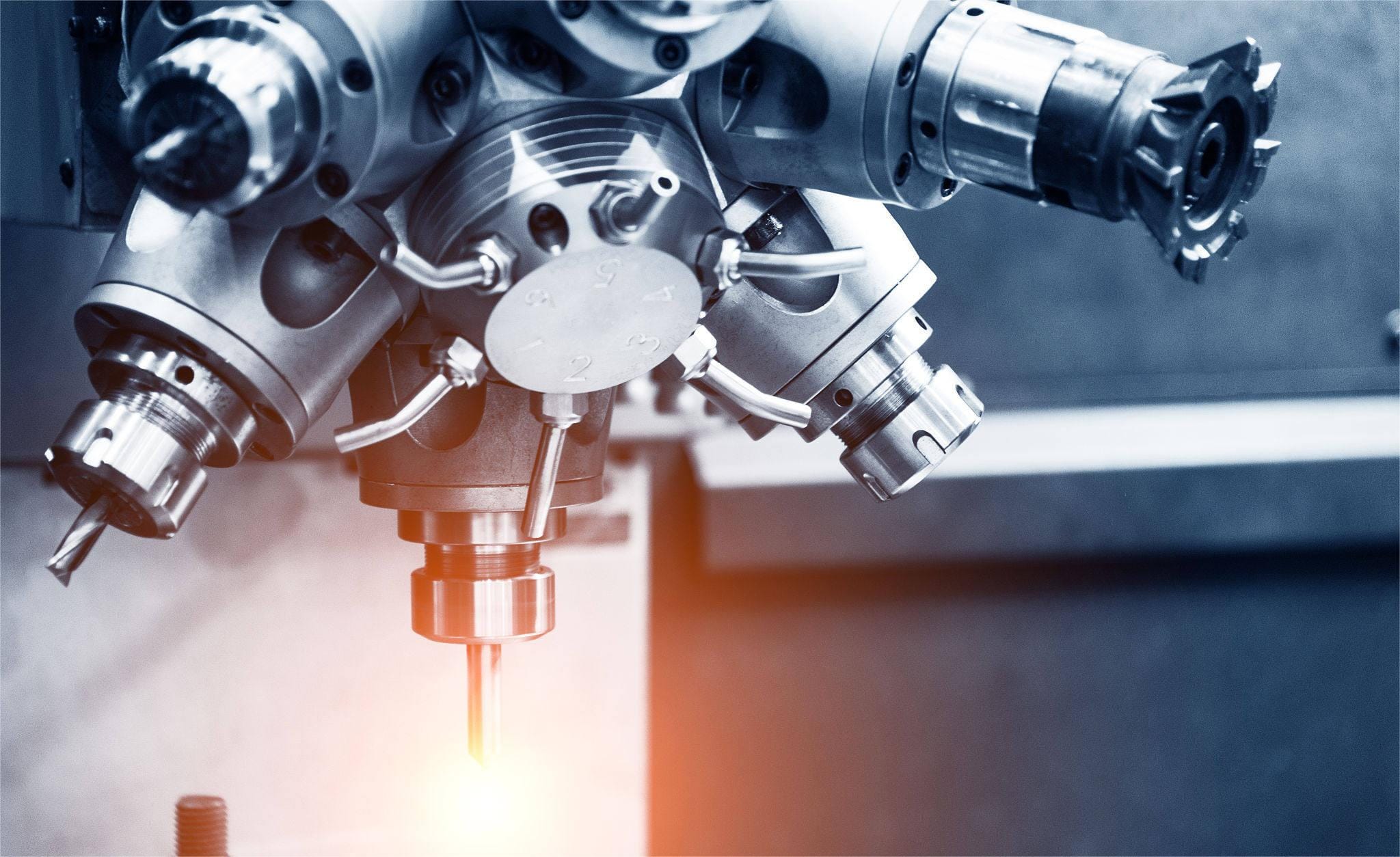

CNC or Computer Numerical Control, refers to an automated machine tool equipped with a program control system. This system logically processes predefined control codes or symbolic instructions, decoding them into numerical signals for the control device. Once processed, the numerical control device generates various control signals to direct the machine’s movements, allowing it to automatically shape parts according to specified designs.

CNC machines execute a wide range of manufacturing tasks, including cutting, drilling, milling, and grinding, with high precision and speed. They facilitate the creation and modification of parts from materials like metal, wood, and plastic, serving diverse industries and offering manufacturers a variety of functions.

The CNC system consists of three primary components: a drive/motion system, a feedback system, and a command function. Overall, the automation provided by CNC machines typically results in faster and more accurate part production compared to manual methods.

How Does a CNC Machine Work?

A CNC (Computer Numerical Control) machine tool is an automated processing device widely utilized in modern manufacturing. Its operation involves several key steps:

1.Programming: The first step is to translate the designed part drawings into a format the CNC machine can understand, typically using CAD (Computer-Aided Design) or CAM (Computer-Aided Manufacturing) software. Users create a 3D model and define cutting paths and tool parameters within this software.

2.Generating G-code: The CAD/CAM software converts the model into G-code, a standard set of instructions that the CNC system recognizes. This code specifies how to move the tool, adjust speeds, and rotate it.

3.Inputting the program: The generated G-code is entered into the CNC machine’s control system, either manually or via a dedicated programmer.

4.Starting and initialization: After powering on the CNC machine, it performs initialization tasks, such as returning to a reference point, to ensure all axes are accurately positioned.

5.Executing the program: Once the program is loaded, the operator can select automatic mode and start the machine. It will then follow the G-code instructions to control the tool’s movements and process the workpiece accurately.

6.Monitoring and adjustment: During machining, operators can monitor the machine’s status in real time. They can make adjustments as needed and stop the process immediately if any issues arise.

This streamlined process allows for precise and efficient manufacturing in various industries.

Basic Elements of CNC Machine System

The basic elements of a CNC (Computer Numerical Control) machine system include:

Input and Output Devices

These serve as the data entry and exit points for the CNC system, facilitating communication. They encompass the devices used for input and output, along with the processing and control data, machine parameters, and specified axis positions.

Machine Tool

The machine tool is essential for precise motion control, managing tool movement along the machine shaft through a servo motor, ball screw, and linear guide rail. The servo system ensures accurate positioning of the spindle and bed, allowing for real-time adjustments via the feedback system. This category includes lathes, milling machines, routers, and other machines designed for cutting and shaping materials. Typically, CNC machine tools have a sliding table and a spindle, with the table moving along the X and Y axes and the spindle operating on the Z axis.

MCU (Machine Control Unit)

Known as the “brain” of the system, the MCU interprets and executes instructions from the input device, usually in G-code format, translating them into precise movements for the machine tool. It comprises key hardware components like the central processing unit (CPU), memory (ROM/RAM), an operation panel, display, and keyboard, along with control software such as a programmable logic controller (PLC). The MCU manages motion control, spindle speed, tool changes, and other vital machining parameters.

Mechanical Structure

This includes components like the machine tool base, workbench, gears, spindle, and others, forming the physical foundation of the CNC machine tool. These elements provide critical support and positioning for movement.

Feedback System

The feedback system measures position and speed for closed-loop control, integrating position sensors, speed sensors, and amplification circuits. Devices such as encoders and linear scales work with servo motors to deliver positional feedback to the MCU, allowing it to monitor and adjust the machine tool’s position during operations, ensuring accuracy and precision.

Workholding Devices

Workholding devices are crucial for securing the workpiece during machining. These may include vises, clamps, chucks, fixtures, and specialized tools. Effective workholding is essential for maintaining the stability and accuracy of the workpiece throughout the machining process.

Operator Interface

The operator interface facilitates interaction between the machine operator and the CNC system. This can be a control panel, a computer screen, or a combination of both. Through this interface, operators can input commands, monitor machining progress, and adjust parameters as necessary.

In summary, the CNC system consists of seven key components: input and output devices, machine tool, MCU, mechanical structure, feedback system, workholding devices, and operator interface. Together, these elements enable CNC machines to accurately execute preset procedures.

Different Types of CNC Machines

CNC machines can be categorized in various ways, but the most fundamental classification is based on their design and function. This approach divides CNC machines into the following types:

Types of CNC Machines According to the Number of Axes

The types of CNC machines can be further segmented according to the number of axes. Here are some common types:

- 2-Axis CNC Machine

2-axis CNC machines represent the most basic type of CNC system, featuring two movement axes: the X-axis (vertical) and the Y-axis (horizontal). These machines control the movement of the tool or workpiece, allowing for straightforward operations. According to the classification of digital machine tools, 2-axis CNC machines fall under the category of inductive control, which is defined by the number of linked axes.

These machines primarily perform basic straight-line cuts or drill holes in materials, typically processing one surface of a workpiece without needing to relocate it. They are among the simplest CNC systems, ideal for precision machining applications that demand high accuracy and consistency.

Key Advantages of 2-Axis CNC Machines:

High Precision: Computer-controlled motion eliminates human error, ensuring consistency and high precision throughout the process. This is vital in industries like aerospace, healthcare, and automotive, where even minor deviations can lead to serious issues.

Cost-Effectiveness: 2-axis machines are generally less expensive than multi-axis options, making them an attractive choice for small to medium businesses or newcomers to the market.

Extensive Applications: These machines are widely utilized across various industries, including aerospace, automotive, medical, and architecture, and are likely to maintain a significant presence in manufacturing for the foreseeable future.

However, 2-axis CNC machines do have limitations. They can only machine parts in the X and Z axes, preventing them from performing complex 3D machining tasks. For applications requiring intricate geometries, it may be necessary to consider CNC machines with three or more axes.

- 3-Axis CNC Machine

The most common type of CNC machine is the 3-axis CNC machine, capable of manufacturing parts in 2.5 dimensions. It features three axes of movement: the X, Y, and Z axes (depth). However, the two rotating axes are used between machining operations rather than simultaneously.

This machine can operate on all six surfaces of a standard square or rectangular block, though the block must be repositioned for each surface. Typically, the workpiece remains fixed during operation. If the machine allows for rotation around an axis, it is classified as 3 + 1 machining, which includes three linear axes and one rotating axis.

Advantages:

Ease of Programming and Operation: The relative simplicity of the 3-axis CNC machine makes it easy to program and operate, making it ideal for novice businesses.

Cost-Effectiveness: With low purchase and maintenance costs, it offers an affordable option for many companies.

Multifunctionality: While not as versatile as 5-axis machines, 3-axis CNC machines can handle most common geometric parts with high accuracy and strict tolerances.

High Productivity: These machines enhance overall production efficiency by minimizing the time required to manually reposition the workpiece.

However, they do have limitations when it comes to complex designs and geometries. While 3-axis CNC machines are widely used across various industries for their user-friendliness and cost efficiency, businesses facing intricate geometries may need to consider upgrading to higher precision 5-axis CNC machines.

- 4-Axis CNC Machine

In addition to the X, Y, and Z axes, a 4-axis CNC machine includes a rotational axis known as the A-axis. This A-axis allows the cutting tool torotate along the X-axis, making the machine ideal for creating cutouts and arc-shaped cuts. In quad CNC milling, the fourth axis enhances the movement of the cutting tool, enabling rotation around the X-axis. Many four-axis CNC machines also allow the workpiece to rotate, referred to as the B-axis, allowing the machine to function as both a milling machine and a lathe.

Key Advantages of 4-Axis CNC Machines:

Improved Machining Accuracy: The simultaneous control of three linear axes (X, Y, and Z) and one rotating axis results in higher accuracy and the ability to process complex shapes.

Reduced Setup Time: For polyhedral parts or those requiring multiple sides to be machined, the 4-axis CNC machine can complete all operations without repositioning the workpiece, significantly cutting down on setup time and manual intervention.

Enhanced Production Efficiency: This machine can process multiple surfaces in a single clamping, improving overall production efficiency while minimizing errors and time costs associated with multiple setups.

Suitability for Complex Geometries: The 4-axis CNC machine excels at machining parts with intricate geometries, such as spiral surfaces and polyhedral components, which can be challenging or impossible to achieve with a 3-axis machine.

With its innovative rotating axis design, the 4-axis CNC machine offers greater machining accuracy, efficiency, and flexibility, making it ideal for high-precision and complex parts processing tasks.

- 5-Axis CNC Machine

5-Axis CNC milling introduces an additional rotating axis compared to four-axis CNC machines. The fifth axis rotates around the Y-axis, known as the B-axis. Some machines also allow the workpiece to rotate, sometimes referred to as the B-axis or C-axis. This capability makes 5-axis CNC machining ideal for producing complex precision parts, such as artificial prosthetics, aerospace components, titanium parts, oil and gas machinery, and military products.

Key Advantages of 5-Axis CNC Machines:

Improved Surface Finish: The ability to maintain optimal cutting angles throughout the machining process reduces tool deflection, resulting in smoother surfaces and finer details.

Fewer Setups: Unlike traditional three-axis machines, 5-axis machines can process multiple surfaces simultaneously, significantly decreasing the number of setups required for different sides.

Enhanced Processing Efficiency: With the capability to machine up to five surfaces in a single clamping, 5-axis machines improve processing accuracy, shorten cycle times, and accelerate production.

Adaptability to Complex Geometries: These machines excel at machining parts with intricate shapes and polygonal structures by adjusting the tool’sdirection to access various workpiece sides.

Greater Operational Flexibility: The additional rotation axes provide operators with enhanced mobility, allowing for more precise and complex cuts from any angle.

The 5-axis CNC machine plays a crucial role in modern manufacturing. Despite its higher cost and the need for skilled operators, its substantial benefits make it a preferred choice for producing many complex components.

- 6-axis CNC Machine

The B-axis of a 6-axis CNC machine introduces a third rotating direction for the cutting tool or workpiece. This machine features six degrees of freedom, incorporating the traditional X, Y, and Z linear axes along with three rotational axes: the A-axis (rotation around the X-axis), B-axis (rotation around the Y-axis), and C-axis (rotation around the Z-axis). These additional axes enable the machine to execute more complex operations in three-dimensional space, allowing for the creation of parts with virtually any surface finish by utilizing all possible movement directions of the cutting tool and workpiece.

The advancement of 6-axis CNC machines is evident not only in their diverse applications but also in the pursuit of cost-effective solutions, the fulfillment of specific industry requirements, innovations in industrial robot control systems, and progress in high-precision control technologies.

- 7-Axis CNC Machine

7-axis CNC machines consist of three axes for moving the cutting tool, three axes for rotating the workpiece, and a seventh axis—known as the E-axis—that rotates the arm holding the cutting tool. This design allows for the creation of highly complex parts.

Typically, 7-axis CNC machines feature three linear axes for tool movement, enhancing processing accuracy while minimizing the need for subsequent machining steps. This efficiency leads to improved overall production rates.

Types of CNC Machines Based on the Control System

According to the different control system, CNC machine tools can be divided into the following types:

- Point-to-Point Positioning Control

In a point-to-point (PTP) CNC controller, the cutting tool moves to a predefined point before machining begins at that location. PTP is commonly used for operations like drilling, spot welding, and tapping, where simultaneous positioning and machining are not required. This system focuses primarily on accurately positioning the tool and is ideal for drilling or stamping tasks.

The PTP system is the simplest form of CNC control, emphasizing precise position control. Its key advantages include high accuracy and fast operation, but it struggles with complex curves and intricate shapes.

- Straight Cut Positioning Control

A straight-cut positioning control system allows the cutting tool to move while simultaneously processing the workpiece, with both operations occurring at a regulated rate. In this system, machining follows a straight line, making curved cuts impossible. It is designed for tasks that require linear motion, such as cutting and welding.

This system offers greater flexibility than a point-to-point system and can accommodate some simple curves and shapes.

- Contouring Path CNC System

The continuous path CNC system, also known as a contouring path CNC system, is designed to produce highly intricate components. Unlike point-to-point or straight-cut positioning systems, it can simultaneously control the cutting tool’s position across multiple axes. This capability enables the creation of curved surfaces (contours) on the workpiece.

Commonly used in milling and turning operations, the continuous path CNC system excels at following complex curves, making it ideal for high-precision tasks such as mold manufacturing and machining precision parts. Its greater flexibility and adaptability allow it to handle a wide variety of shapes with ease.

Types of CNC Machines by Servo Control Mode

The servo control mode is a crucial aspect of CNC machine tool performance. It can be broadly categorized into the following types:

- Open Loop Control CNC Machine

An open-loop control machine operates without a detection or feedback device. In this system, the driving circuit amplifies power, allowing a single-direction instruction signal to drive the stepping motor that moves the machine table.

The main advantage of open-loop control machines is their low cost, making them widely accessible. However, they suffer from poor precision and stability, which can compromise job quality. This control system does not utilize feedback signals to adjust output; instead, it functions based on preset procedures and parameters, without adapting to actual output conditions.

- Closed-Loop Control CNC Machine

A closed-loop control machine utilizes a linear displacement-detecting device, incorporating control strategies such as current, velocity, and position loops. This device is typically installed on the moving parts or the tabletop of the machine tool. The comparator in the CNC device receives the actual displacement and compares it to the programmed instruction value.

While maintaining stability in a closed-loop control CNC machine can be challenging, this system offers superior accuracy. By continuously adjusting parameters, closed-loop controllers enhance both the static and dynamic performance of the machine.

- Semi-Closed Loop Control CNC Machine

The semi-closed loop control CNC machine tool operates as a hybrid between open-loop and full closed-loop systems, featuring its own unique structure and characteristics. In this system, a position feedback detection device is typically installed at the end of the servo motor or screw, allowing it to indirectly capture position information by measuring the speed and revolutions of the servo motor. This data is then sent back to the CNC device for processing.

The actual displacement of the worktable is determined using an angular displacement detection device, which is commonly mounted at the end of the servo motor shaft or ball screw.

- Full-software CNC system

A full-software CNC system, also known as soft CNC or software numerical control, is a system that performs functions like interpolation, bit control, and PLC through software modules. Its main advantage lies in its high flexibility and openness, as all control logic is managed by computer software instead of relying on hardware controllers. In practice, full-software CNC systems can be developed on various operating system platforms.

How to Select the Best CNC Machine Type?

Choosing the right CNC machine involves understanding the specific CNC processes you need and the materials you’ll be working with. Key factors to consider include the machine’s weight, work radius, speed, availability of spare parts, and power consumption. Here are some tips for selecting the ideal CNC machine:

| Define Your Application: | Identify the intended use and required manufacturing processes, such as milling, turning, or grinding. This will guide your machine selection. |

| Consider Part Size: | Measure the maximum dimensions and weight of the parts to ensure the machine’s work envelope can accommodate them. |

| Assess Accuracy Requirements: | Determine the level of precision needed. Tighter tolerances require machines with high rigidity and precision components. |

| Material Compatibility: | Ensure the machine can handle the materials you plan to use. Harder materials, like steel, need more robust machines. |

| Evaluate Production Volume: | For higher volumes, consider machines with faster rapid traverses, automatic tool changers, and larger tool magazines. |

| Complex Machining Needs | Assess whether you require 4 or 5-axis machining for complex 3D shapes, with 5-axis offering greater flexibility. |

| Brand Reliability: | Choose a brand known for reliability and precision. |

| User-Friendly Interface: | Prioritize machines with intuitive controls and software compatible with your CAM system. |

| Training and Support: | Look for suppliers that offer comprehensive operator training and responsive technical support. |

| Repairability: | Ensure your technicians can easily repair the machine and that spare parts are readily available to minimize downtime. |

| Power Requirements: | Check the machine’s power needs and make necessary adjustments in your workspace. |

Common materials for CNC machines include aluminum, polymer composites, and iron cast. Iron cast is ideal for heavy-duty tasks, while other materials may suffice for lighter jobs. Like any equipment, CNC machines may require repairs over time, so having access to spare parts and technician support is crucial.

By carefully evaluating these factors, you can choose the CNC machine that best suits your needs, budget, and production requirements. Consulting with suppliers or industry experts can also provide valuable insights tailored to your situation.

Conclusion

A CNC machine is a computer-controlled machining system that automates many manufacturing tasks traditionally performed by hand. This automation enhances production efficiency, reduces waste, and eliminates human error. Mastering the operation of various CNC machines significantly boosts overall efficiency, highlighting the importance of learning to operate different types.

As a highly efficient, accurate, and flexible manufacturing tool, CNC machines are vital in modern industry, with applications spanning aerospace, automotive, and mold manufacturing. With advancing technology, these machines are evolving towards greater intelligence and automation. In the future, the integration of new technologies will continue to drive innovation and development opportunities in the manufacturing sector.

FAQS

What is CNC machining 6 most common CNC machines?

CNC Milling Machine: Cuts and shapes materials using rotating tools.

CNC Lathe: Produces cylindrical parts by rotating the workpiece.

CNC Router: Engraves and cuts various materials, often in woodworking.

CNC Plasma Cutter: Uses plasma technology to cut through metals with precision.

CNC Laser Cutter/Engraver: Employs lasers for accurate cutting and engraving.

CNC Water Jet Cutter: Utilizes high-pressure water to cut through materials.

What are the 7 major parts of a CNC machine?

The CNC system comprises seven key components:

Input and Output Devices: Facilitate data entry and communication.

Machine Tool: Performs the actual machining operations.

MCU (Microcontroller Unit): Controls the machine’s functions.

Mechanical Structure: Provides the physical framework for the machine.

Feedback System: Monitors performance and accuracy.

Workholding Devices: Secure the workpiece during machining.

Operator Interface: Allows user interaction and control.

How are CNC machines classified?

Based on the Number and Arrangement of Axes:

3-Axis

4-Axis

5-Axis

Based on the Method of Material Removal:

Cutting

Abrasive

Thermal

Erosive

Based on the Type of Motion Control System:

Open-loop

Closed-loop

Based on Machine Structure and Application:

Milling Machine

Lathe

Router

Grinder

Laser/Plasma/Waterjet Cutter

EDM

Based on Size and Capacity:

Mini/Benchtop

Standard

What are the 5 common types of CNC machines?

Here are five common types of CNC machines:

CNC Milling Machines: Used for cutting and shaping materials with rotating tools.

CNC Lathes: Ideal for producing cylindrical parts through rotational cutting.

CNC Routers: Designed for cutting and engraving various materials, often used in woodworking.

CNC Plasma Cutters: Utilize plasma technology to cut through metals with precision.

CNC Laser Cutters/Engravers: Use lasers for cutting and engraving materials with high accuracy.

What is the difference in CNC machines?

The main difference between CNC machine tools and traditional machining lies in control mode and precision. CNC machines use servo motors to achieve high-precision and reproducible axial movements, enabling control over multiple axes, feed rates, and spindle speeds. They also incorporate features such as tool wear monitoring and safety systems. In contrast, traditional machining relies more on manual operation, resulting in lower precision and flexibility.