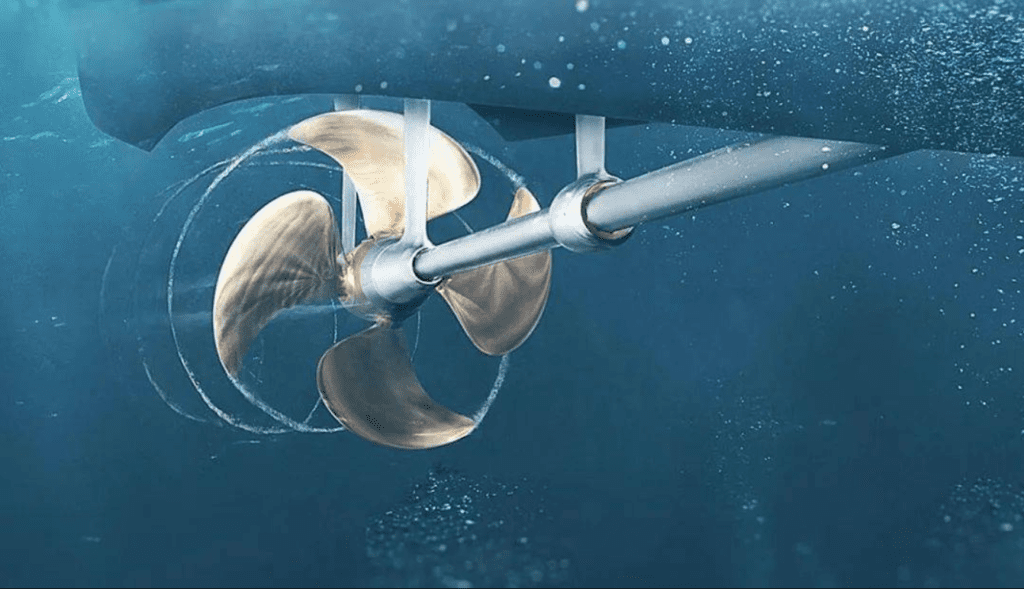

Marine propeller impellers operate constantly in hostile seawater, where multiple corrosion processes threaten their durability and performance. From barnacles clinging onto the blades to cavitation pits eroding the metal, these mechanisms dramatically reduce propulsion efficiency and increase fuel costs—Maritime studies estimate such losses account for up to a third of a vessel’s total drag. Moreover, untreated corrosion can compromise structural integrity, potentially causing catastrophic failures at sea. Addressing this multifaceted challenge requires a comprehensive strategy, combining smart material selection, advanced coatings, electrochemical protection, biofouling prevention, and regular maintenance. In this article, we explore common corrosion types and their hazards, examine proven protective technologies, offer practical maintenance guidelines, and spotlight future trends like graphene coatings and smart sensors. Whether you’re a naval architect, marine engineer, or fleet manager, this guide will equip you with essential insights to safeguard propeller impellers for safer, more efficient marine operations.

Corrosion Types and Their Impact

Designing marine propeller impellers for long-term durability requires a thorough understanding of the unique corrosion mechanisms present in ocean environments. Unlike terrestrial conditions, marine applications expose metal components to a constant interplay of mechanical, chemical, and biological factors that intensify wear and degradation. Each type of corrosion affects not only the structural integrity of the impeller but also its hydrodynamic efficiency, contributing to increased energy consumption and operational risks.

Marine Biofouling

In seawater, marine organisms such as barnacles, algae, and tubeworms tend to colonize impeller surfaces. This biofouling layer disrupts smooth flow, elevates hydrodynamic drag, and accelerates corrosion by trapping moisture and salts. Over time, biofouling not only reduces propulsion efficiency but also creates micro-environments that promote localized corrosion under the organic mass.

Galvanic Corrosion

When dissimilar metals, such as copper alloys and stainless steel, are in electrical contact within saltwater, galvanic cells form, causing the less noble metal to corrode rapidly. This form of electrochemical corrosion is particularly dangerous in composite assemblies, where improper material pairing can lead to rapid structural degradation even in seemingly stable components.

Cavitation Erosion

High-speed rotation of impellers generates low-pressure zones where vapor bubbles form and collapse violently. These micro-bubble implosions release shockwaves that create pitting on the impeller surface, a phenomenon known as cavitation erosion. This is especially severe at blade tips or near abrupt geometrical transitions, weakening structural integrity over time.

Erosive Corrosion

The constant impact of fast-moving water, especially when laden with sand or particulate matter, gradually strips away the protective oxide layers of metals. This repeated mechanical wear allows corrosive agents to penetrate deeper into the material, resulting in a combined effect of abrasion and chemical degradation that shortens component life.

Corrosion Hazards

Unchecked corrosion has far-reaching consequences. It can reduce propulsion efficiency by increasing surface resistance, potentially elevating fuel consumption by up to 33%. Moreover, ongoing structural weakening can lead to sudden impeller failure, compromising vessel safety and incurring substantial repair and downtime costs. Thus, proactive corrosion identification and mitigation are essential for marine impeller design and maintenance.

Protective Measures and Applied Technologies

To extend the operational life of marine propeller impellers and maintain optimal efficiency, engineers must employ an integrated corrosion prevention strategy. This approach blends advanced materials, surface treatments, electrochemical systems, and anti-fouling methods. Each solution plays a specific role in counteracting corrosion mechanisms caused by saltwater, biofouling, and mechanical stress.

Material Choices

Selecting the right base material is the first line of defense. Duplex stainless steel, such as SAF2507, offers exceptional resistance to both pitting and crevice corrosion thanks to its dual-phase microstructure. It is especially effective in high-chloride marine environments and retains strength under mechanical stress.

Composite materials, like nickel-aluminum bronze and carbon fiber-reinforced polymers, are gaining traction due to their combination of structural robustness and corrosion resistance. These hybrids are not only lightweight and durable but also reduce galvanic reaction risks when paired with compatible components.

Coating Techniques

Protective coatings form a critical barrier between the impeller and corrosive seawater. Nano-ceramic coatings are particularly effective due to their self-healing characteristics, which help resist cavitation and reduce fouling. Their fine structure enables rapid damage repair at the micro-scale, preserving surface integrity.

Advanced multi-layer coating systems are often used on propellers operating in aggressive waters. A typical setup includes an epoxy primer for adhesion, an elastic buffer to absorb mechanical stress, and a silicone-based topcoat that resists bio-adhesion and chemical attack. These layers work synergistically to provide long-lasting protection.

Electrochemical Protection

Electrochemical strategies offer active corrosion suppression. Sacrificial anodes—commonly made of zinc, magnesium, or aluminum—corrode preferentially, protecting the main metallic structure from degradation. These are simple, cost-effective solutions widely used in both commercial and military vessels.

For more precise and adjustable control, Impressed Current Cathodic Protection (ICCP) systems apply an external electric current to counteract corrosive electrochemical reactions. ICCP is especially suitable for high-value marine systems requiring consistent corrosion mitigation with minimal maintenance.

Biofouling Control

Marine biofouling, if left unmanaged, exacerbates surface degradation. Chemical methods include biocidal coatings that release active agents to prevent larval attachment. However, environmental regulations increasingly limit their use due to ecological concerns, prompting a shift to alternative technologies.

Physical anti-fouling strategies—such as propeller guards, high-pressure water cleaning, and ultrasonic devices—offer environmentally friendly solutions. These methods disrupt settlement and remove organisms without harming marine life, making them ideal for sustainable operations.

Maintenance and Operational Best Practices

To ensure reliable long-term performance of propeller impellers in corrosive or marine environments, day-to-day maintenance and vigilant operational oversight are indispensable. Proactive routines help mitigate wear, reduce efficiency losses, and delay costly repairs or replacements. In high-performance systems, small lapses in upkeep can quickly escalate into structural damage or functional failure.

Shaft Lubrication

Proper lubrication is essential for maintaining smooth rotational movement and preventing seizing or accelerated wear. Using grease formulations rich in polytetrafluoroethylene (PTFE) creates a durable, water-resistant barrier that resists both corrosion and mechanical breakdown. These greases are especially effective in saline or high-humidity environments.

Routine application not only ensures frictionless movement but also prevents micro-abrasions that could expose metal surfaces to corrosive attack. Maintenance teams should check lubricant condition during each operational cycle and reapply after extended submersion or exposure to aggressive fluids.

Surface Cleaning

Fouling and mineral buildup reduce hydrodynamic efficiency and exacerbate corrosion by trapping moisture and chemicals against the metal surface. Regular cleaning, using mild detergents or low-pressure abrasives, removes these deposits and helps preserve surface coatings.

Establishing a cleaning schedule aligned with environmental exposure (e.g., monthly in warm seawater zones) ensures that surfaces remain clean without damaging protective films. Special attention should be given to blade edges, as accumulated debris can unbalance the impeller and degrade performance.

Corrosion Monitoring

Early detection of corrosion allows for timely intervention and extends component life. Electrochemical potential readings provide a non-invasive means of assessing corrosion rates and identifying anodic/cathodic hotspots. These readings can be taken using portable reference electrodes during routine inspections.

Underwater video monitoring further complements corrosion assessment, offering visual confirmation of pitting, fouling, or surface wear. High-resolution imaging enables documentation and trend tracking, helping maintenance teams prioritize resources and plan preemptive actions.

Defect Repair and Recoating

Casting flaws such as porosity or surface cracks, if left unrepaired, can lead to premature failure under dynamic load. Weld repair using corrosion-resistant filler metals restores structural continuity while minimizing thermal distortion.

After welding, the affected area must be re-treated and recoated to reinstate full protective performance. Applying compatible coatings (e.g., epoxy primers followed by anti-fouling topcoats) ensures the repair site integrates seamlessly into the surrounding protection scheme, preserving both integrity and aesthetics.

Future Developments

As marine environments grow harsher and sustainability standards tighten, the future of impeller protection lies in the integration of advanced materials and intelligent monitoring. These innovations not only extend equipment lifespan but also align with global efforts to reduce environmental impact. The next generation of marine impeller technology will be shaped by smart design, bioinspiration, and materials science.

Graphene-Enhanced Coatings

Graphene-based marine coatings are gaining traction for their exceptional mechanical strength and chemical inertness. These ultrathin layers provide superior barrier properties, drastically reducing corrosion rates and preventing biofouling adhesion even under prolonged submersion.

In addition to durability, graphene coatings reduce drag and fuel consumption, contributing to operational efficiency. Their electrical conductivity also makes them suitable for hybrid protective systems that combine passive coatings with active monitoring.

Advanced Alloys: Alloy 50 and Beyond

Emerging alloys such as Alloy 50 exhibit outstanding resistance to cavitation erosion and chloride-induced corrosion. Designed for high-flow marine environments, these materials are particularly suited for impeller blades exposed to repeated pressure fluctuations.

Compared to conventional stainless steels, these high-performance alloys offer greater fatigue strength and extended service intervals, making them a cost-effective long-term investment despite higher upfront material costs.

Smart Sensors and Monitoring Systems

Embedded sensors are revolutionizing impeller diagnostics by enabling real-time data collection on corrosion potential, temperature changes, and flow-induced stress. These systems support predictive maintenance, alerting operators to early-stage damage before it affects performance.

When integrated with cloud platforms and AI analytics, smart monitoring enables remote diagnostics and optimization of maintenance schedules, significantly reducing unplanned downtime and repair costs.

Biomimetic Coating Technologies

Inspired by lotus leaves and shark skin, biomimetic coatings create ultra-smooth, non-stick surfaces that resist fouling and biofilm formation. These coatings use micro- and nano-patterns to repel water and contaminants without relying on toxic chemicals.

Their passive, chemical-free nature makes them ideal for environmentally sensitive marine zones, helping vessels meet international maritime emission and pollution standards while maintaining high propeller efficiency.

Eco-Friendly Antifouling Agents

New-generation antifouling solutions leverage biodegradable compounds and targeted biocides that degrade safely in marine environments. These agents disrupt biofouling lifecycles without harming non-target marine organisms.

When used in conjunction with durable base coatings, eco-friendly antifouling systems offer long-term surface cleanliness while supporting marine biodiversity and reducing ecological disruption in high-traffic waterways.

Conclusion

Effective corrosion prevention for marine impellers demands a comprehensive, multi-layered defense that integrates advanced materials, coating technologies, electrochemical protection, and intelligent maintenance. Selecting corrosion-resistant materials—such as duplex stainless steel, nickel-aluminum bronze, and ceramic composites—forms the structural backbone of durability. These materials not only withstand harsh saltwater and high-velocity flow but also reduce susceptibility to cavitation and wear. Complementing material choice, high-performance coating systems—such as multi-layer epoxy-silicone combinations or emerging nanocoatings—offer critical protection by forming resilient barriers that minimize drag, resist fouling, and improve fuel efficiency.

In addition to passive defenses, active electrochemical protection systems like sacrificial anodes and ICCP further reduce galvanic degradation in mixed-metal assemblies. Long-term performance is enhanced through predictive maintenance, which leverages underwater inspection, electrochemical sensors, and AI-driven monitoring to identify issues before they escalate. Looking forward, environmentally sustainable innovations—such as eco-friendly biocides and bio-inspired surface treatments—are set to redefine corrosion control. Together, these strategies ensure that marine impellers operate reliably, efficiently, and in alignment with evolving environmental standards.