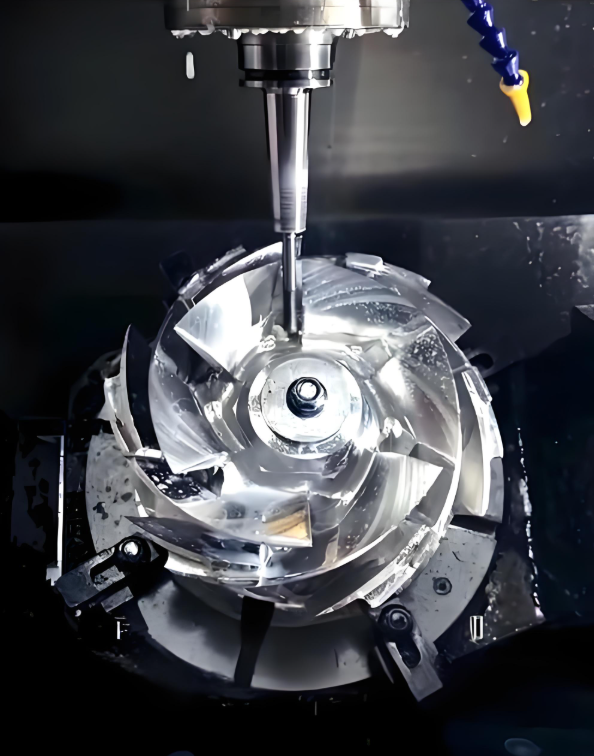

In high-end manufacturing sectors such as aerospace, automotive, and energy, impeller machining has attracted significant attention owing to its geometric complexity and high requirement for precision. As a very important component in turbomachinery, the efficiency and quality of impeller machining have a direct impact on the overall machine performance. Owing to the complicated configuration and highly variable surfaces of integral 3D impellers, it is of great significance to select an appropriate machining method. Point milling and flank milling, two of the most well-known five-axis machining methods, both possess their own advantages and are widely used in impeller manufacturing.

Point milling and flank milling possess very different machining principle and application purpose. Point milling is a process with contact between the tool tip and workpiece and is very appropriate for precision machining of small-radius or complex surface areas. Flank milling, in contrast, involves engaging the blade surface with the tool’s side cutting edges and enables higher material removal rates and is thus more suitable for comparatively regular or open-area surfaces. Both these methods vary in terms of tool path planning, tooling, machining productivity, and surface quality and must be chosen carefully considering the impeller’s given geometry and performance.

This article provides a comprehensive comparison of point milling and flank milling from the aspects of definition, process characteristics, application range, and key considerations in tooling and trajectory optimization. The objective is to give a complete technical guideline to producers and engineers for the improvement of impeller machining quality and efficiency and to meet the increasingly high requirements of high-end component manufacturing.

What Is Point Milling?

Point milling is one of the most prevalent forms of localized cutting, which is characterized by “point contact” between the workpiece and tool while machining. Compared to face milling where the contact occurs over a large surface area, point milling is featured with extremely small surface area contact, which is normally established using ball-end or flat-end mills. Cutting takes place mainly at the tip of the tool, enabling precise material removal over small surface areas—making it ideal for cutting complex surfaces.

In impeller production, point milling utilizes five-axis simultaneous machining flexibility in dynamically varying the orientation of the tool to closely follow complicated 3D profiles. Point milling is conventionally used in the finishing stage, especially where there is a need for high surface integrity and dimensional accuracy in blade surfaces. Due to the limited contact area, point milling generates smaller cutting forces, which has the tendency of minimizing blade deformation and increasing surface smoothness and stability in machining.

What Is Side Milling?

Side milling is a type of machining operation in which the side edge of the cutting tool is engaged for material removal. It is often carried out by end mills, cylindrical cutters, or barrel tools that execute linear or curvilinear scanning on the workpiece surface. Side milling possesses greater contact area and material removal rate than point milling and is especially applicable for high-efficiency operations.

In impeller machining, side milling is commonly applied in roughing and semi-finishing operations, particularly in regions of high curvature or open flow channels, i.e., outer edges of blades or main passage areas. Its ability to remove excessive material rapidly considerably improves overall machining efficiency and shortens production cycles.

Also, side milling excels at dealing with flat or low-curvature surfaces and therefore is very suitable for quickly establishing the general profile of a part and creating a good foundation for subsequent finishing operations.

What Are The Process Characteristics Of Point Milling?

Point milling is an important machining process of the impeller due to its accuracy and flexibility, especially well-suited to machine intricate geometric configurations.

- High Flexibility:It allows the cutting tool to approach the workpiece from various directions, hence especially well-suited to machine non-developable surfaces or twisted blades of the impeller, effectively handling complex structures.

- Concentrated Cutting Force:Cutting forces are concentrated at the tool tip, requiring high-rigidity tools and fixtures to avoid vibration and ensure machining accuracy and stability.

- Excellent Surface Quality:Point milling can be employed in finishing processes, achieving high surface finish (e.g., Ra < 0.4μm), which improves the aerodynamic efficiency of the impeller.

- High-Accuracy Machining:Suitable for machining operation with stringent tolerance control on small impellers or complex flow channels.

- Complex Tool Path:Relies on five-axis machining centers and advanced CAM software to develop precise tool paths with no interference with surrounding blades.

- High Rigidity Requirement:Due to the concentration of cutting points, the tool must be extremely high in rigidity and be implemented along with a stable fixture system in order to withstand cutting loads.

- Wide Application Range:Flexible for use on micro-impellers, medical micro-pump impellers, and other miniature products. Typical applications include aero engine compressor impellers, gas turbine cooling channel cutting, and precision grinding of medical centrifugal pump blades.

What Are The Process Characteristics Of Side Milling?

Side milling, very effective in material removal and production, is widely used in the roughing and semi-finishing stages of impeller manufacturing.

- Large Material Removal Rate: Side milling can remove enormous amounts of material with excellent speed and is thus highly suitable for impeller roughing and semi-finishing large impellers.

- High Rigidity Tool Demand: The operation needs high-rigidity side milling cutters of big diameter to support heavy cutting forces and provide machining stability.

- Efficiency-focused: Side milling is focused on productivity and suits high-volume production applications that need quick completion.

- Low To Moderate Precision: Side milling has relatively lower surface quality and precision compared to point milling but is still utilized in the stages where high precision is not required.

- Simple Tool Paths: Side milling tool paths are relatively simple, suitable for plane or low-curvature surface machining, which keeps the programming simple.

Side milling is typically applied in first-time impeller machining, as a basis for follow-up finishing machining. Side milling’s principal advantage is excellent machining efficiency, especially when machining large-sized workpieces, large surfaces, and roughing operations, allowing rapid removal of materials. Side milling cutters also possess extended tool life and provide stable machining performance.

However, side milling also has its limitations, particularly in adapting to complicated spatial surfaces and slim, closed channel flow, where it is less adaptable and functional.In use such as large aerospace impellers, wind turbine rotors, and nuclear power circulation pump impellers, side milling is usually utilized as pre-machining or half-finishing, with sufficient gap space and allowance provided for subsequent precision point milling.

What Impeller Machining Scenarios Is Point Milling Suitable For?

Point milling performs superlative performance in machining impellers, especially for high precision and surface quality required in a given situation. Its major areas of use are:

High-precision Machining

Point milling can be used for parts such as aero-engine impellers with stringent tolerance requirements, ensuring accuracy and stable functioning.

Complex Surface Machining

For slit flow channels, twisted blades, and non-developable surfaces, point milling ensures multi-angle flexible cutting for complex geometry requirements.

Finishing Stage

Point milling provides great surface finish quality, which addresses the high aerodynamic and friction performance requirements of impellers.

Machining Small Impellers

Point milling uses precise tool control to ensure machining quality for very small or heavily detailed impellers.

In Which Impeller Machining Scenarios Is Side Milling More Suitable?

Side milling is also greatly appreciated in impeller machining due to its high material removal and high production efficiency.

Impeller Machining Of Large Size

Side milling can be used to perform rough machining of large impellers, allowing bulk material removal at high speed to enhance overall processing speed.

High-Efficiency Production Needs

In critical time-to-market production environments, the high material removal rate of side milling greatly minimizes machining time.

Roughing And Semi-Finishing Operations

Side milling is mostly used in the first operations of impeller machining to create a solid geometric foundation and provide a smooth surface for the subsequent finishing operation.

Lower Precision Requirements

If surface finish or dimension accuracy is not the most important consideration, side milling gives an economic machining process.

Simple Or Flat Curved Surfaces

In areas where there is not much curvature and open geometry, side milling offers efficient processing by using simpler tool paths and minimal programming complexity.

Apart from that, side milling is most appropriate for gigantic curved surfaces and open-structure components, such as wind turbine impellers, water pump impellers, and nuclear circulation pump blades. It is most ideal for machining operations that call for efficiency rather than robust accuracy, making it the most suitable technical assistance in high-volume production setups.

Point Milling Vs Side Milling:What Are The Main Differences

In terms of machining approach, point milling involves point contact, whereas side milling involves surface contact. From the tool perspective, point milling typically uses ball-end mills, while side milling more often utilizes cylindrical, disc-shaped, or barrel-shaped cutters.

| Comparison Dimension | Point Milling | Side Milling |

| Contact Type | Point contact between tool and workpiece | Large-area side contact between tool and workpiece |

| Tool Type | Ball-end mills, tapered ball-end mills | Side-edge mills, barrel cutters, disc mills |

| Machining Stage | Mainly for finishing | Mainly for roughing and semi-finishing |

| Machining Efficiency | Low, but with high precision | High, but less adaptable to complex regions |

| Surface Quality | Can achieve extremely high surface finish | Moderate surface quality |

How To Choose Point Milling Or Side Milling

While machining an impeller, the selection of Point Milling or Side Milling requires careful processing requirement analysis. Precision-Efficiency Balance: Point Milling is suitable when high precision and fine surface finish are required, while Side Milling is suitable when there is a requirement for high material removal rates and production efficiency.

Impeller Geometric Complexity And Size:Small impellers or intricate geometry are optimally milled using Point Milling. Large impellers having plain and open surfaces are optimally machined using Side Milling.

Machining Stage:Side Milling can be applied for roughing and semi-finishing operations to quickly profile the workpiece. Point Milling needs to be used in the finishing operation to achieve high accuracy and surface finish.

Machine Tool Capabilities:Five-axis machining centers add to the flexibility of Point Milling for complex geometries, and even low-end three-axis or four-axis machines can meet the simple path requirements of Side Milling.

Material Properties: Point Milling in high-strength materials (i.e., superalloys) will require more frequent tool changeouts due to localized cutting forces, whereas Side Milling requires stiff, heavy-duty tools to handle higher loads and stability.

By evaluating these variables in depth, producers are able to choose the most suitable milling approach to maximize machining quality and overall production efficiency.

Conclusion

Five-axis impeller machining, point milling and side milling are not mutually exclusive but must be integrated and used flexibly according to different machining stages and structural areas. In aero-engine impeller machining, for example, side milling is universally used first for the rough removal of bulk material in the flow passages, and then point milling is used to perform high-precision finishing on the blade surfaces, achieving both high efficiency and good product quality.

Generally, point milling and side milling are two fundamental milling methods in impeller machining with their respective strengths. Point milling is characterized by high precision and improved surface quality, making it especially suitable for small impellers and high requirement finishing operations. Side milling, on the other hand, is distinguished by high efficiency and high material removal rate, making it more suitable for large impellers and roughing or semi-finishing operations.

Through a comprehensive understanding of the process features, application conditions, and tooling requirements of the two processes, the manufacturers can select or merge point milling and side milling based on actual needs with flexibility. Together with the ongoing improvement of five-axis machining technology and intelligent CAM programming, the strategic application of the two machining methods will further enhance the efficiency and quality of impeller production, injecting new vitality into high-end equipment manufacturing.