Imagine a component that drives fluid movement with simplicity, efficiency, and versatility, powering everything from wastewater pumps to industrial mixers. Open impellers, with their exposed blades and rugged design, are engineering marvels that excel in challenging environments. Dive into this comprehensive guide to discover their unique design, diverse applications, and why they’re a cornerstone of fluid machinery.

What Are Open Impellers?

Ever wondered what makes open impellers stand out in fluid machinery? These robust components, with exposed blades and no enclosing shrouds, are designed for efficiency and adaptability. Curious about their structure and role? Explore their definition, design, and why they’re a go-to choice for engineers.

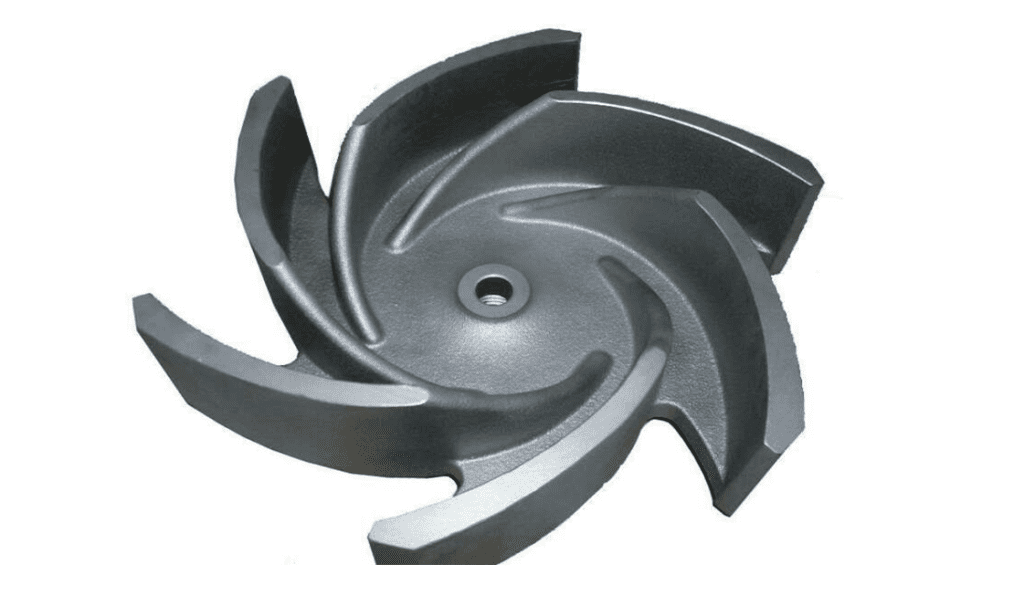

Open impellers feature blades mounted on a central hub without front or back shrouds, allowing direct contact with the fluid. This design simplifies manufacturing and maintenance, making them cost-effective for applications involving solids or viscous fluids. Typically made from materials like stainless steel, cast iron, or polymers, open impellers are used in pumps, mixers, and agitators. Their exposed blades enable easy cleaning and reduce clogging, ideal for wastewater treatment, slurry pumping, and chemical processing. The simplicity of their design also allows for customization, optimizing fluid dynamics for specific operational needs.

Key Characteristics Of Open Impellers

What sets open impellers apart from their enclosed counterparts? Their unique design offers distinct advantages in handling challenging fluids. Intrigued by how these characteristics enhance performance? Delve into the core features that make open impellers indispensable in fluid systems.

The defining trait of open impellers is their lack of shrouds, which reduces weight and manufacturing complexity. This design allows them to handle fluids with high solid content, such as slurries or fibrous materials, without clogging. Open impellers are less efficient than closed designs but excel in applications where ease of maintenance and solids handling are priorities. Their blades, often backward-curved or radial, are engineered to balance flow and pressure, ensuring reliable performance in demanding conditions like mining or wastewater management.

Advantages Of Open Impellers

Open impellers are designed with vanes attached to a central hub without shrouds enclosing the sides. This design offers unique advantages in applications involving solids, viscous fluids, and maintenance-sensitive environments. Their simplicity and flexibility make them a popular choice in wastewater, food, and chemical processing systems.

Excellent For Solids Handling

Open impellers allow larger or fibrous solids to pass through more easily, minimizing clogging. This makes them ideal for slurry pumping, wastewater treatment, and pulp and paper operations where particulate matter is common.

Easier Cleaning And Maintenance

With no sidewalls to trap debris, open impellers are easier to clean and inspect. This feature is particularly useful in industries requiring frequent maintenance or hygiene control, such as food processing and pharmaceuticals.

Adjustable Clearance

Open impellers allow for easy adjustment of the impeller-to-casing clearance, helping to maintain pump efficiency over time as wear occurs. This reduces downtime and improves energy efficiency without the need for full replacement.

Cost-Effective Production

Because of their simpler geometry, open impellers are generally less expensive to cast and machine. This can lower the total cost of ownership, especially for applications with frequent wear or requiring multiple units.

Lightweight Design

Open impellers use less material and have lower mass than enclosed designs, reducing the load on pump shafts and bearings. This can improve energy efficiency and reduce mechanical wear in continuous-use systems.

Applications Of Open Impellers Across Industries

Open impellers are widely used in sectors requiring efficient handling of solids, slurries, and variable fluid conditions. Their versatile, low-maintenance design makes them ideal for industries where frequent cleaning, high wear, and material flexibility are necessary for optimal pump performance and reliability.

Wastewater Treatment

Open impellers excel in wastewater systems where fibrous solids, sludge, and grit are common. They resist clogging and are easy to clean, making them the go-to choice in municipal sewage plants, industrial effluent systems, and stormwater treatment facilities.

Food And Beverage Processing

In food applications, open impellers facilitate gentle handling of viscous or solid-laden liquids, such as sauces, fruit pulp, or dairy. Their easy-to-clean structure supports strict hygiene requirements and reduces cross-contamination risk between product batches.

Chemical And Pharmaceutical Industries

For fluids that may contain abrasives or suspended particles, open impellers provide chemical resistance and consistent flow. They are used in reactors, mixers, and transfer pumps where product integrity and flexibility are crucial.

Pulp And Paper Mills

Open impellers handle fibrous pulp slurries efficiently, making them a mainstay in paper manufacturing. Their ability to pass stringy, irregular materials without jamming is critical to maintaining continuous operation in these high-volume facilities.

Mining And Slurry Handling

In the mining sector, open impellers are used in pumps that transport mineral slurries and abrasive fluids. Their durable, open design extends service life under extreme wear conditions and reduces the need for frequent pump overhauls.

Agriculture And Irrigation

Pumps with open impellers are found in agricultural irrigation systems where water may carry organic matter, sediment, or fertilizer particles. They offer consistent performance and are easy to service in field conditions.

Marine And Shipboard Applications

On ships, open impeller pumps are used for bilge, ballast, and wastewater management systems. Their ease of maintenance and ability to handle debris make them reliable in challenging maritime environments.

Manufacturing Open Impellers

The production of open impellers involves a balance of precision engineering, durable material selection, and efficient finishing techniques. These impellers must be crafted to exact specifications to ensure smooth fluid dynamics, high wear resistance, and long service life in industrial environments with variable and sometimes harsh operating conditions.

Material Selection

Depending on the application, open impellers are manufactured from a range of materials such as stainless steel, bronze, brass, cast iron, or engineering plastics. The choice depends on the fluid’s characteristics—abrasiveness, temperature, chemical makeup—and cost considerations.

Casting Or Forging

For metal impellers, the process typically begins with sand casting, investment casting, or forging. Sand casting is common for large or less complex impellers, while investment casting allows for tighter tolerances and smoother finishes in smaller, more precise designs.

CNC Machining

After the raw impeller is cast or forged, it undergoes CNC (Computer Numerical Control) machining. This stage refines the vane angles, hub dimensions, and mounting interfaces to match specific hydraulic and mechanical requirements. High precision is essential for balance and flow efficiency.

Surface Finishing

Finishing processes such as grinding, polishing, or coating (e.g., epoxy or ceramic layers) enhance the impeller’s surface quality, reduce friction, and improve resistance to wear, cavitation, or corrosion. In sanitary applications, polishing is critical to meet hygiene standards.

Quality Inspection

Manufacturers perform rigorous inspections, including dimensional checks, material integrity assessments, and hydraulic performance testing. This ensures the impeller meets performance and safety specifications before installation.

Challenges And Solutions In Open Impeller Design

Open impellers offer many benefits, but they also present unique design challenges. Engineers must balance wear resistance, flow efficiency, and structural strength—especially when handling solids or variable fluid conditions. Below are the most common challenges in open impeller design and the strategies used to overcome them.

Wear and Erosion from Solids

- Problem: Open impellers are often exposed to abrasive particles, which can wear down the vanes and reduce performance over time.

- Solution: Use wear-resistant alloys (e.g., hardened stainless steel or duplex metals) or apply protective coatings like tungsten carbide or ceramic to extend service life.

Cavitation Risk

- Problem: Improper vane design or excessive clearance can cause cavitation, leading to vibration, pitting, and damage.

- Solution: Optimize impeller geometry using CFD (Computational Fluid Dynamics) simulations and ensure tight manufacturing tolerances. Installing anti-cavitation vanes and maintaining proper NPSH (Net Positive Suction Head) also helps.

Imbalance And Vibration

- Problem: Open impellers can become unbalanced from wear, trapped debris, or manufacturing imperfections, causing operational vibration.

- Solution: Perform dynamic balancing during manufacturing and conduct regular inspections. Designing self-cleaning vane geometries can prevent debris accumulation.

Efficiency Loss Over Time

- Problem: As the impeller-to-volute clearance increases due to wear, hydraulic efficiency decreases.

- Solution: Incorporate adjustable wear rings or allow for easy impeller clearance adjustment during maintenance. Regular inspections help maintain tight operating tolerances.

Mechanical Strength

- Problem: With less structural support than closed impellers, open impellers may deform under high stress or speed.

- Solution: Use FEA (Finite Element Analysis) during design to reinforce critical stress points and choose high-strength materials suited to the application.

Limited High-Pressure Application Suitability

- Problem: Open impellers are less suitable for high-pressure or high-head systems where structural rigidity is crucial.

- Solution: For such applications, either reinforce the impeller hub or consider hybrid designs, such as semi-open or closed impellers, to combine strength with solids-handling ability.

Frequent Maintenance Needs

- Problem: In harsh or variable conditions, open impellers may require more frequent cleaning or inspection.

- Solution: Design for tool-free access and quick disassembly. Some modern pumps feature quick-release volutes and front-pull impellers for faster maintenance.

Comparing Open Impellers To Closed And Semi-Open Impellers

Choosing the right impeller design is crucial for pump performance, maintenance, and efficiency. Open, semi-open, and closed impellers each have strengths and limitations depending on the application. Here’s how they compare in terms of construction, efficiency, solids handling, cost, and typical use cases.

| Feature / Type | Open Impeller | Semi-Open Impeller | Closed Impeller |

| Construction | Vanes attached to hub, no shrouds | Back shroud, no front shroud | Fully enclosed by front and back shrouds |

| Efficiency | Low to moderate | Moderate | High |

| Solids Handling | Excellent – handles fibrous/abrasive solids well | Good – handles some solids/slurries | Poor – prone to clogging in dirty/slurry fluids |

| Ease of Maintenance | Very easy to clean, inspect, and adjust | Moderate – easier than closed | More complex – tighter tolerances, harder to service |

| Wear Resistance | Moderate – exposed to wear | Moderate | High – protected surfaces |

| Durability | Lightweight, lower mechanical strength | Stronger than open | Very strong – suitable for high-pressure use |

| Cost | Low – simple and inexpensive to manufacture | Moderate | High – complex geometry and tighter specs |

| Typical Applications | Wastewater, food processing, pulp, mining | Chemical processing, slurries, general industry | HVAC, clean water, petrochemical, high-pressure systems |

Conclusion

Open impellers are a testament to engineering ingenuity, offering simplicity, versatility, and performance in fluid-handling systems. Their ability to manage solids-laden fluids, coupled with cost-effective manufacturing, makes them indispensable in wastewater, mining, agriculture, and food processing. Advancements in materials, five-axis machining, and smart technology are propelling their evolution, ensuring relevance in sustainable and high-performance applications. Whether you’re an engineer, manufacturer, or industry enthusiast, open impellers provide reliable solutions for a dynamic future. Explore their potential and harness their power in your next project.