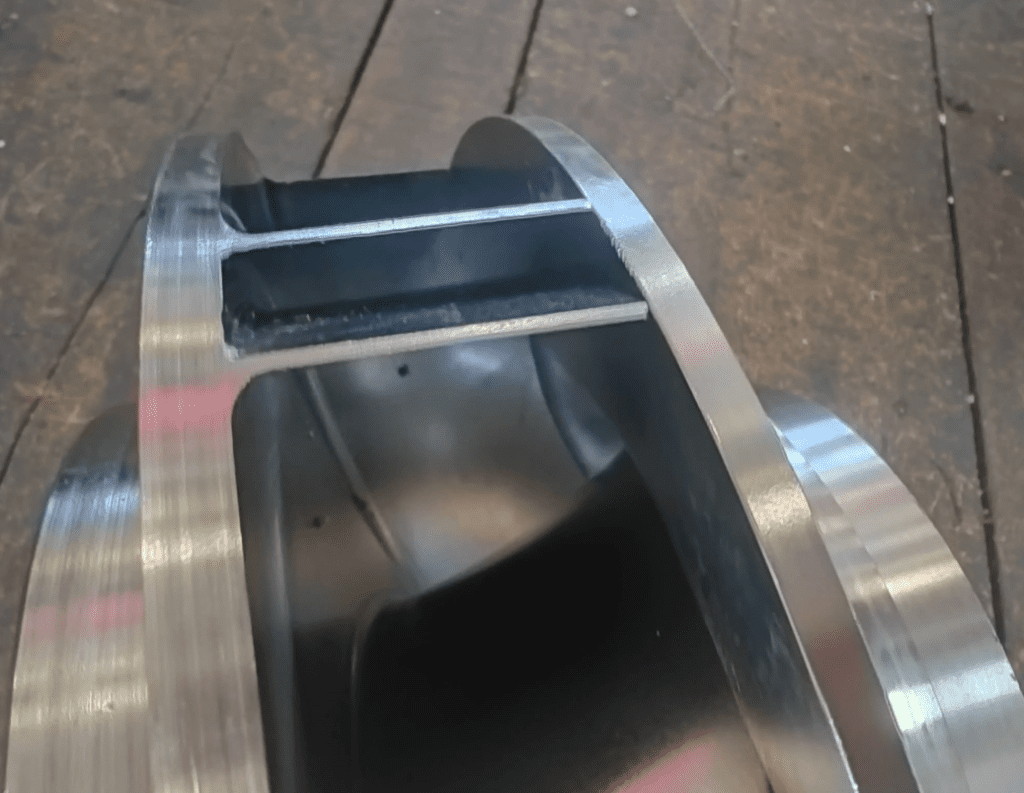

Machined impellers are critical components in pumps, compressors, and turbines, ensuring optimal performance. This guide explores the machining process, comparing it with casting, and covers materials, techniques, and quality control for high-precision impeller production.

Five Common Materials For Machined Impellers And Selection

Material selection is pivotal for machined impeller performance and durability. This section details five common materials, their properties, and selection criteria, helping you choose the optimal material for specific industrial applications.

Stainless Steel (304/316L)

Stainless steel, particularly grades 304 and 316L, is widely used for its excellent corrosion resistance and mechanical durability. These materials perform well in chemically aggressive environments, with 316L offering enhanced resistance due to its molybdenum content. This makes them suitable for chemical processing equipment, marine pumps, and fluid systems exposed to salts or mild acids. Selection of stainless steel is generally driven by its corrosion performance, making it the preferred material for components exposed to moisture, chemicals, or marine atmospheres.

Aluminum Alloy (6061/7075)

Aluminum alloys such as 6061 and 7075 are valued for their lightweight nature and high strength-to-weight ratios. These alloys also offer good machinability and moderate corrosion resistance, especially when anodized. As a result, they are frequently used in aerospace components, mobile fluid systems, and applications where weight reduction is crucial. The choice of aluminum is guided by the need to reduce system mass while maintaining sufficient structural integrity, especially in transport or mobile equipment.

Titanium Alloy (TC4)

Titanium alloy TC4 (also known as Ti-6Al-4V) stands out for its exceptional combination of strength, heat resistance, and corrosion resistance. It is capable of withstanding high temperatures and aggressive chemical environments, making it ideal for high-performance sectors such as military systems, aerospace turbines, and energy applications. Engineers typically select TC4 when a component must endure high thermal stress, corrosive fluids, or extreme mechanical loads without compromising weight or durability.

Duplex Stainless Steel (2205)

Duplex stainless steel 2205 offers a dual-phase microstructure that combines the strength of ferritic steel with the corrosion resistance of austenitic stainless steel. This results in excellent resistance to chloride-induced corrosion and stress corrosion cracking, making it highly suitable for seawater desalination plants, offshore platforms, and other chloride-heavy environments. It is commonly chosen for its long-term durability and strength under harsh marine or industrial exposure.

High-Strength Steel (42CrMo)

42CrMo is a high-strength alloy steel known for its exceptional toughness, wear resistance, and ability to handle high mechanical loads. It is often used in demanding applications such as heavy-duty pump and valve impellers, hydraulic components, and high-pressure industrial equipment. The selection of 42CrMo is typically based on performance needs where abrasion, impact, and pressure are major factors, ensuring reliability and a long service life in rugged operating conditions.

Choose based on operating conditions (corrosion, temperature, load) and cost. For example, 316L suits chemical applications, while TC4 is ideal for aerospace.

Six Core Machining Processes For Impellers

Machining impellers requires advanced techniques to achieve precision and performance. This section outlines six key processes, from CNC turning to ultrasonic machining, detailing their roles in crafting high-precision impellers.

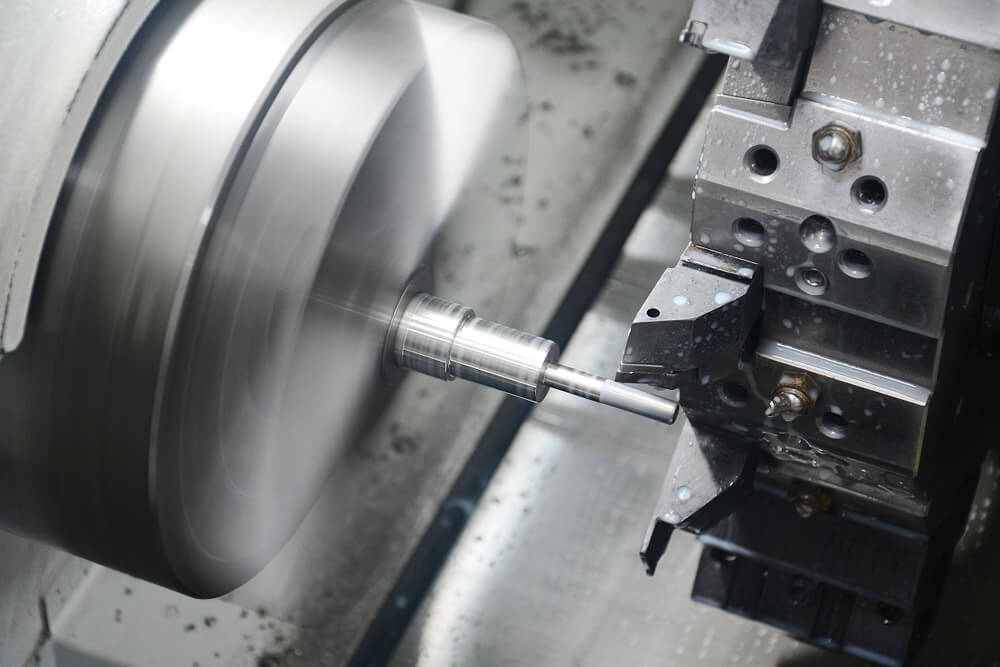

CNC Turning

- Process: Precision machining of impeller hubs and end faces.

- Equipment: CNC lathes (e.g., Haas, Okuma).

- Precision: Achieves tolerances of ±0.01mm.

Five-Axis Milling

- Process: Shapes complex curved flow passages for optimal fluid dynamics.

- Equipment: Five-axis CNC machines (e.g., DMG MORI, Mazak).

- Benefits: Handles intricate geometries with high accuracy.

Electrical Discharge Machining (EDM)

- Process: Uses electrical sparks to machine super-hard materials.

- Applications: Precision machining of titanium or hardened steel impellers.

- Precision: Achieves micro-level tolerances (±0.005mm).

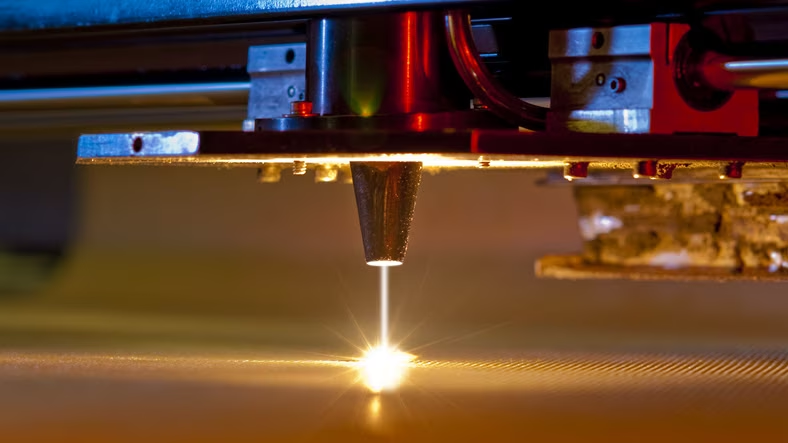

Laser Cutting

- Process: High-precision cutting for thin-plate impellers.

- Applications: Initial blank preparation for lightweight impellers.

- Advantages: Fast, accurate, minimal material waste.

Grinding and Polishing

- Process: Achieves ultra-smooth surfaces (Ra≤0.8μm).

- Equipment: Precision grinders, polishing machines.

- Purpose: Enhances fluid efficiency and corrosion resistance.

Ultrasonic Machining

- Process: Uses high-frequency vibrations for composite or brittle materials.

- Applications: Specialized impellers with non-metallic components.

- Advantages: Minimal thermal damage, high precision.

Four Key Technical Metrics For Machined Impellers

Achieving high-precision impellers requires strict control of technical metrics. This section examines four critical indicators—dimensional accuracy, dynamic balancing, surface integrity, and fatigue life—ensuring optimal impeller performance.

Dimensional Accuracy

Dimensional accuracy is a critical quality control factor in impeller manufacturing, particularly for components used in precision flow systems. The industry standard typically follows the IT7 tolerance class, which equates to a dimensional tolerance of ±0.02 mm. This level of precision ensures that impeller geometries align accurately with design specifications, maintaining flow efficiency and mechanical balance. Verification is commonly performed using Coordinate Measuring Machines (CMM), which provide high-resolution measurements of complex geometries, including vane angles, hub profiles, and flow passage dimensions.

Dynamic Balancing Grades

Proper dynamic balancing is essential to minimize vibration, reduce bearing wear, and ensure long-term operational stability. The ISO 1940 standard classifies impeller balance grades, with G2.5 used for standard industrial applications such as pumps and compressors, and G1.0 designated for high-speed or aerospace turbines where balance precision is critical. Balancing is achieved using high-precision equipment from manufacturers like Schenck and Hofmann. These machines detect mass distribution errors and guide corrective measures such as counterweight placement or strategic drilling.

Surface Integrity

Maintaining surface integrity is vital to preventing premature failure and ensuring aerodynamic or hydrodynamic efficiency. Impeller surfaces must be free of micro-cracks, pitting, and uncontrolled residual stresses that could propagate under cyclic loading. To ensure this, manufacturers employ non-destructive testing (NDT) techniques such as dye penetrant inspection, magnetic particle testing, or ultrasonic testing. Additionally, stress analysis may be conducted to evaluate residual stresses resulting from machining or heat treatment processes, thus ensuring structural reliability.

Fatigue Life

Fatigue life is a key performance indicator for impellers subjected to cyclic loading, especially in high-speed or high-pressure applications. Factors affecting fatigue life include material selection, heat treatment quality, and precision in machining. Inadequate surface finishes or thermal inconsistencies can initiate fatigue cracks, ultimately leading to failure. To assess endurance under operational stress, fatigue testing machines simulate real-world loading cycles, typically aiming to validate life cycles exceeding 10^6 or even 10^7 cycles for critical systems. This data ensures long-term durability and reduces unplanned maintenance.

Five Common Defects In Impeller Machining And Solutions

Machining impellers can encounter defects that compromise quality. This section analyzes five common issues—deformation, chatter marks, dimensional errors, residual stress, and imbalance—offering practical solutions.

Machining Deformation

Machining deformation often arises due to improper clamping methods or excessive cutting forces during the manufacturing process. When a workpiece is not properly supported or restrained, it may warp or shift under the stress of cutting, leading to deviations from intended dimensions. To mitigate this, fixture designs should be optimized to provide uniform support, and cutting parameters—such as feed rate and depth of cut—should be carefully adjusted to reduce mechanical stress on the material.

Surface Chatter Marks

Surface chatter marks, recognizable by their irregular wavy patterns on machined surfaces, typically occur due to insufficient tool rigidity or improper spindle speed settings. These vibrations not only affect surface quality but also compromise dimensional accuracy. Enhancing the stiffness of the cutting tool and tool holder, along with fine-tuning spindle RPM to match the material’s cutting characteristics, can significantly reduce or eliminate chatter during machining operations.

Dimensional Errors

Dimensional inaccuracies can result from thermal expansion of the machine structure or progressive tool wear during prolonged machining. As equipment heats up, its components expand, subtly shifting the cutting path, while dull tools fail to maintain consistent geometry. Solutions include implementing thermal compensation software in CNC systems and conducting real-time monitoring of tool wear, enabling timely tool replacement and consistent part dimensions.

Residual Stress

Residual stresses are internal forces retained in a component after machining or heat treatment, often caused by aggressive cutting or improper thermal cycling. These stresses can lead to part distortion over time, especially under load or temperature fluctuations. To address this issue, techniques like vibration stress relief or optimized heat treatment cycles are employed. These methods help redistribute internal stresses evenly, stabilizing the part’s structure for long-term reliability.

Excessive Imbalance

Excessive imbalance in a machined impeller may be caused by uneven material removal, resulting in asymmetrical mass distribution. This can lead to vibrations, reduced efficiency, and premature bearing failure during operation. To resolve this, it’s essential to ensure symmetric machining paths and equal allowance distribution. Final dynamic balancing using precision equipment further corrects any residual imbalance, ensuring smooth rotation under operational speeds.

Machined Impeller Vs. Cast Impeller: Eight Key Comparisons

Understanding the differences between machined and cast impellers aids in process selection. This section compares eight critical dimensions, highlighting the strengths of machined impellers for precision applications.

| Dimension | Machined Impeller | Cast Impeller |

| Dimensional Accuracy | ±0.02 mm | ±0.1 mm |

| Material Strength | No casting defects | Possible porosity |

| Production Cycle | 3–7 days | 10–15 days |

| Batch Suitability | Small/medium batches | Large batches |

| Surface Quality | Ra 0.4–0.8 μm | Ra 1.6–3.2 μm |

| Cost | High | Low |

| Design Flexibility | Extremely high | Mold-limited |

| Dynamic Balance | G1.0 achievable | Typically G6.3 |

Conclusion

Selecting a reliable machined impeller service is essential for achieving superior performance and long-lasting operation in demanding applications. The first key criterion is to choose suppliers with recognized quality certifications such as AS9100 or ISO13485. These certifications indicate that the manufacturer follows strict quality management systems, ensuring consistent production standards and traceability. This is particularly important in sectors like aerospace, medical devices, and energy, where even minor defects can have significant consequences. Working with certified suppliers also reduces risks associated with material quality, manufacturing processes, and final product reliability.

Another critical factor is the availability of advanced manufacturing equipment. Top-tier suppliers should have access to five-axis CNC machining centers, which allow for precise and complex impeller geometries to be produced with tight tolerances. In-process measurement systems integrated into the production line enable continuous quality control, catching deviations early and reducing waste. Furthermore, material certification and process validation are vital; suppliers must provide detailed documentation proving that raw materials meet required specifications and that manufacturing processes adhere to industry standards. Finally, dynamic balancing capability is a must-have for high-speed applications. Achieving a G1.0 dynamic balance grade minimizes vibrations during operation, enhancing both the efficiency and lifespan of the impeller and associated machinery. Confirming these capabilities before selecting a supplier ensures that you invest in quality components that perform reliably under demanding conditions.