CNC (Computer Numerical Control) machining has revolutionized architecture with its precision, efficiency, and versatility. This technology, which uses computer-controlled tools to shape materials, is transforming how architects design and builders construct, enabling complex geometries, sustainable practices, and innovative workflows. This article delves into the multifaceted applications of CNC machining in architecture, exploring its technical foundations, practical uses, real-world case studies, advantages, challenges, and future trends, offering a comprehensive resource for architects, engineers, and industry enthusiasts.

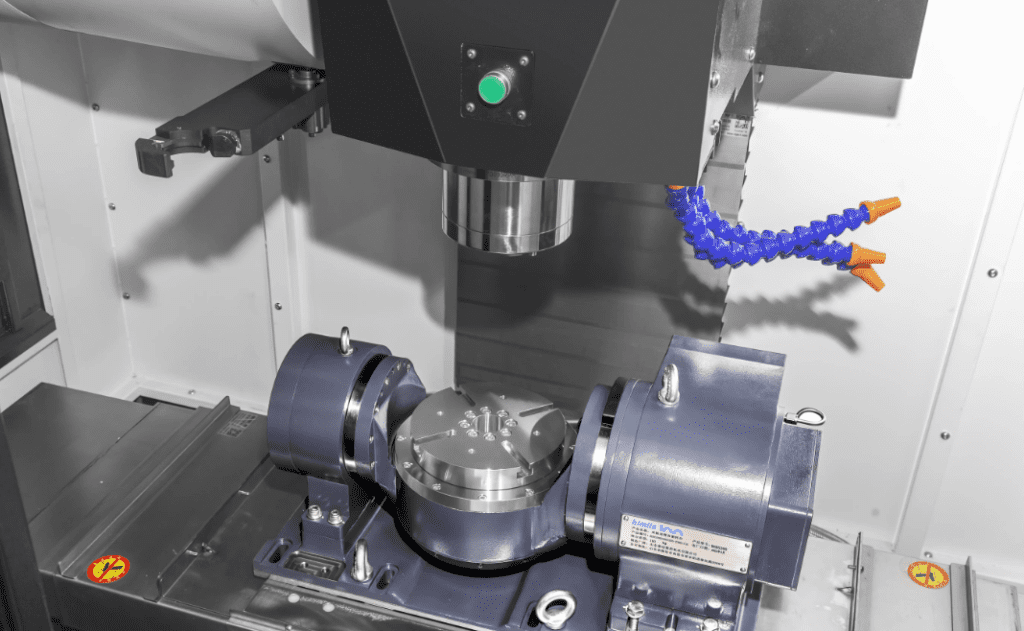

Overview Of CNC Machining Technology

CNC machining leverages computer-controlled tools to precisely shape materials like metal, wood, and stone, offering architects unparalleled precision and flexibility in creating intricate designs and structural components for modern architecture.

CNC machining is an automated manufacturing process where pre-programmed software directs the movement of machine tools to shape raw materials. By converting digital designs into numerical instructions, CNC systems control equipment like milling machines, lathes, laser cutters, plasma cutters, and 3D printers. These machines process a wide range of materials, including metals (steel, aluminum), wood, stone, glass, and advanced composites, making them ideal for architectural applications.

The hallmark of CNC machining is its precision, achieving tolerances as fine as 0.01 mm, far surpassing traditional manual methods. This accuracy is critical in architecture, where intricate details and complex geometries are increasingly common. For instance, CNC machines can carve intricate patterns into stone facades or cut metal panels with exacting precision for curtain walls. Additionally, CNC machining offers repeatability, ensuring consistent quality across large production runs, which is vital for modular construction and prefabrication.

Another key advantage is its ability to accelerate prototyping. Architects can quickly produce scale models or full-size components to test designs, reducing the time from concept to execution. With the integration of Building Information Modeling (BIM), CNC machining aligns seamlessly with digital design workflows, enabling a smooth transition from 3D models to physical components. This digital-to-physical pipeline enhances efficiency, minimizes errors, and supports the growing trend of parametric and computational design in architecture.

CNC machining’s material versatility further enhances its value. It can handle traditional materials like timber for structural elements, modern composites for lightweight facades, or even experimental materials like bio-based polymers. By enabling precise material use, CNC machining reduces waste, aligning with sustainable building practices. As architecture embraces digital transformation, CNC machining has become a cornerstone technology, empowering architects to push creative boundaries and builders to achieve higher efficiency.

CNC machining’s material versatility further enhances its value. It can handle traditional materials like timber for structural elements, modern composites for lightweight facades, or even experimental materials like bio-based polymers. By enabling precise material use, CNC machining reduces waste, aligning with sustainable building practices. As architecture embraces digital transformation, CNC machining has become a cornerstone technology, empowering architects to push creative boundaries and builders to achieve higher efficiency.

CNC Machining In Architectural Design

CNC machining transforms architectural design by enabling the creation of complex, non-linear geometries, empowering architects to explore innovative forms and personalized aesthetics with unprecedented precision and creative freedom.

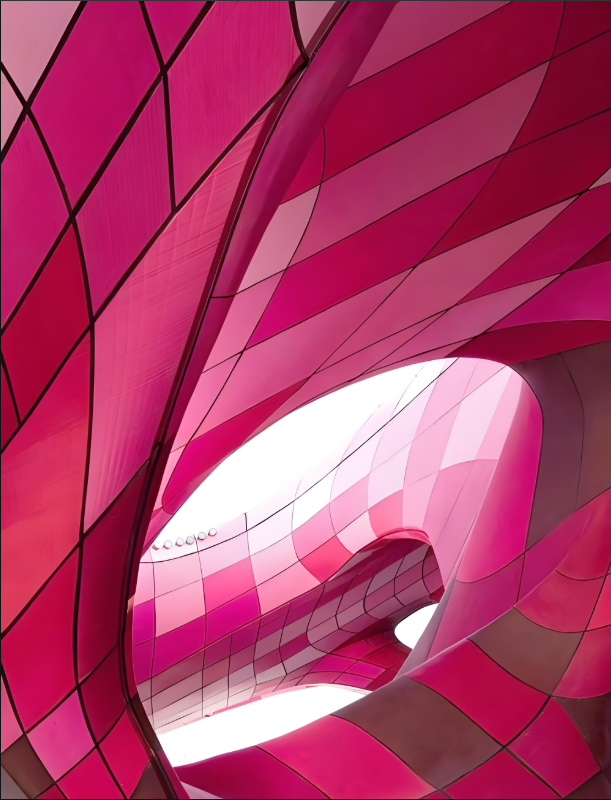

In architectural design, CNC machining is a game-changer for realizing complex and unconventional forms. Modern architecture often features fluid, organic shapes or parametric designs, as seen in the works of architects like Zaha Hadid, Frank Gehry, and Bjarke Ingels. These designs, characterized by curved surfaces, intricate patterns, or irregular geometries, demand precision that manual fabrication struggles to deliver. CNC machining bridges this gap by translating digital models into physical components with exacting accuracy.

One prominent application is in facade design. Contemporary buildings often incorporate custom curtain walls with non-standard shapes, such as curved glass panels or perforated metal screens. CNC laser cutters and milling machines produce these components by following BIM-generated designs, ensuring each piece fits perfectly within the larger system. For example, CNC machining can create intricate lattice patterns on aluminum panels, adding both aesthetic value and functional benefits like shading or ventilation.

CNC machining also excels in creating decorative elements. Architects use it to carve intricate textures into wood, stone, or concrete surfaces, enhancing a building’s visual appeal. For instance, CNC routers can engrave detailed motifs on interior panels or sculpt three-dimensional reliefs on exterior cladding, blending artistry with precision. This capability allows architects to infuse cultural or contextual references into their designs, creating buildings that resonate with their environment.

Model-making is another critical area where CNC machining shines. Architects rely on physical models to visualize concepts, present ideas to clients, or test structural feasibility. CNC machines, such as 3D mills or laser cutters, produce highly detailed scale models, from topographic site representations to intricate structural mock-ups. This rapid prototyping accelerates design iterations, enabling architects to refine ideas quickly and efficiently.

Parametric design, a growing trend in architecture, benefits significantly from CNC machining. Using computational algorithms, architects generate complex forms that would be challenging to fabricate manually. CNC machines translate these digital designs into physical components, ensuring fidelity to the original vision. This synergy between parametric tools and CNC technology has led to iconic structures like the Heydar Aliyev Center in Baku, where flowing curves and seamless surfaces were made possible through CNC fabrication.

By expanding the possibilities of form, texture, and material, CNC machining empowers architects to break free from conventional constraints, fostering a new era of creative expression in architectural design.

CNC Machining In Construction Processes

CNC machining enhances construction by delivering precision and efficiency in producing prefabricated components and facilitating rapid, accurate on-site assembly, revolutionizing modern building practices.

In construction, CNC machining is pivotal for producing prefabricated components, a cornerstone of efficient and sustainable building practices. Prefabrication involves manufacturing building elements off-site, which are then assembled on-site, reducing construction time and environmental impact. CNC machines produce high-precision components like concrete molds, steel beams, and wooden trusses, ensuring seamless integration during assembly.

For example, in steel construction, CNC plasma cutters and drilling machines create beams and columns with precise bolt holes and cutouts, minimizing on-site adjustments. This accuracy is critical for large-scale projects like skyscrapers or bridges, where even minor misalignments can lead to significant delays or safety issues. Similarly, in concrete construction, CNC machines carve intricate molds for precast panels, enabling complex textures or shapes that enhance both aesthetics and functionality.

Modular construction, a subset of prefabrication, relies heavily on CNC machining. Modular buildings are assembled from standardized units, such as wall panels, floor slabs, or entire room modules. CNC machines ensure these units are produced with consistent dimensions, enabling rapid and error-free assembly. For instance, CNC routers can cut timber panels for modular homes, incorporating precise joints or insulation channels, which streamline construction and improve energy efficiency.

CNC machining also supports sustainable construction. By optimizing cutting paths, CNC systems minimize material waste, a key consideration in green building. In timber construction, CNC machines carve traditional joinery techniques, like dovetails or mortise-and-tenon joints, with modern precision, creating durable structures with minimal environmental impact. This blend of tradition and technology is particularly appealing in regions valuing sustainable or vernacular architecture.

In challenging construction environments, such as remote or uneven terrains, CNC machining provides tailored solutions. For example, CNC machines can fabricate custom foundation components based on topographic data, ensuring stability in mountainous or coastal sites. This adaptability makes CNC machining a versatile tool for addressing diverse construction challenges.

For example, a company from Guangzhou named Jieol specializes in tensile structure buildings and relies on CNC machining to fabricate complex Tensile membrane frames, customized steel connectors, and aluminum profiles. These precision-engineered components ensure seamless onsite assembly, even for large-span roofs or curved surfaces. By pre-cutting and pre-drilling each structural piece, Jieol reduces installation time and error, which is crucial for stadiums, commercial pavilions, and temporary event spaces across Asia and beyond.

By enhancing precision, reducing waste, and accelerating production, CNC machining is reshaping construction processes—making them faster, more sustainable, and better aligned with modern architectural demands.

Case Studies Of CNC Machining In Architecture

CNC machining has been instrumental in iconic architectural projects worldwide, with these case studies showcasing its ability to enable complex designs and streamline construction.

Beijing Daxing International Airport, China

Designed by Zaha Hadid Architects, Beijing Daxing International Airport features a sprawling, organic roof structure composed of thousands of custom steel and glass components. CNC machining played a critical role in fabricating these elements, with CNC laser cutters and milling machines shaping steel panels to match the roof’s flowing geometry. The precision of CNC technology ensured tight tolerances, enabling seamless assembly and contributing to the project’s timely completion. This case highlights CNC machining’s ability to handle large-scale, complex projects with exacting requirements.

Sydney Opera House Renovation, Australia

The renovation of the Sydney Opera House, an architectural icon, utilized CNC machining to create intricate interior and exterior elements. CNC laser cutters produced wooden and metal panels with bespoke patterns, preserving the building’s heritage while introducing modern aesthetics. The technology allowed for rapid production of custom components, minimizing disruption to the operational venue and demonstrating CNC machining’s versatility in heritage conservation projects.

3D-Printed Concrete Structures, Netherlands

In the Netherlands, companies like Apis Cor have pioneered CNC-based 3D printing for architecture. Using large-scale CNC 3D printers, they constructed concrete walls for residential buildings, achieving complex curved forms with minimal labor. These projects showcase how CNC machining, extended through 3D printing, can revolutionize construction by enabling rapid, cost-effective, and sustainable building methods.

The Shed, New York City

The Shed, a cultural center in Hudson Yards, features a retractable outer shell made of lightweight ETFE panels supported by a steel framework. CNC machining was used to fabricate the intricate steel components, ensuring precise alignment for the shell’s dynamic movement. This project illustrates CNC machining’s role in creating adaptive, kinetic architecture that responds to functional needs.

These case studies underscore CNC machining’s transformative impact, from enabling avant-garde designs to supporting innovative construction techniques, making it a vital tool in modern architecture.

Advantages And Challenges Of CNC Machining

CNC machining offers unmatched precision and efficiency in architecture, but its adoption faces challenges like high costs and technical complexity, requiring strategic implementation.

Advantages

- Precision and Accuracy: CNC machining achieves tolerances as fine as 0.01 mm, ensuring components meet exact design specifications, critical for complex architectural forms.

- Efficiency and Speed: Automation reduces manual labor, shortens production cycles, and accelerates project timelines, particularly in prefabrication and modular construction.

- Material Versatility: CNC machines process diverse materials, from metals to composites, enabling architects to explore innovative material combinations.

- Sustainability: Optimized cutting and material use reduce waste, supporting eco-friendly construction practices and aligning with green building standards.

- Design Freedom: CNC machining enables the realization of intricate geometries and custom designs, empowering architects to push creative boundaries.

Challenges

- High Initial Costs: CNC equipment, software, and setup require significant investment, which can be prohibitive for smaller architectural firms or contractors.

- Technical Expertise: Operating CNC machines demands specialized training, increasing labor costs and requiring ongoing skill development.

- Maintenance and Upgrades: CNC systems require regular maintenance and software updates, adding to long-term operational expenses.

- Scalability Limitations: While ideal for custom or small-batch production, CNC machining may face challenges in scaling for mass production without substantial infrastructure.

Despite these hurdles, the benefits of CNC machining outweigh its challenges for many architectural applications. As technology advances and costs decline, its accessibility is expected to improve, broadening its adoption across the industry.

Future Trends In CNC Machining For Architecture

CNC machining is poised to redefine architecture through integration with emerging technologies, driving intelligent, sustainable, and innovative solutions for the built environment.

Integration with Artificial Intelligence (AI)

AI is enhancing CNC machining by optimizing tool paths, predicting material behavior, and reducing waste. For example, AI algorithms can analyze design data to generate efficient cutting strategies, minimizing energy use and material consumption. In the future, AI-driven CNC systems could autonomously adapt to project-specific needs, improving productivity and precision.

Advancements In 3D Printing

CNC machining’s integration with 3D printing is revolutionizing construction. Large-scale CNC 3D printers can fabricate entire building components, such as concrete walls or structural frameworks, with minimal labor. Projects like 3D-printed homes in developing regions demonstrate this technology’s potential to address housing shortages sustainably.

Digital Workflow Integration

The rise of BIM and digital twins is deepening CNC machining’s role in architecture. These tools create a seamless digital-to-physical pipeline, where designs are directly translated into CNC instructions. This integration reduces errors, enhances collaboration, and supports real-time project adjustments, streamlining the entire construction process.

Sustainable Manufacturing

CNC machining is aligning with the architecture industry’s push for sustainability. Advanced software optimizes material usage, while new CNC-compatible materials, like recycled composites or bio-based polymers, support eco-friendly designs. In the future, CNC machining could play a key role in achieving carbon-neutral construction.

Robotics And Automation

The convergence of CNC machining with robotic systems is enabling automated construction sites. Robotic arms equipped with CNC tools can perform tasks like cutting, drilling, or assembling components on-site, reducing labor costs and improving safety. This trend is particularly promising for large-scale infrastructure projects.

These trends highlight CNC machining’s potential to drive architectural innovation, blending precision, sustainability, and automation to create smarter, more resilient built environments.

Conclusion

CNC machining is reshaping architecture by enabling precision, efficiency, and creative freedom in design and construction. From crafting intricate facades to producing prefabricated components, it empowers architects and builders to realize ambitious visions with unparalleled accuracy. Real-world projects like Beijing Daxing International Airport and experimental 3D-printed structures demonstrate its transformative impact. While challenges like cost and technical expertise persist, ongoing advancements in AI, 3D printing, and digital workflows are expanding CNC machining’s potential. As the architecture industry embraces sustainability and innovation, CNC machining will remain a pivotal technology, driving the creation of iconic, efficient, and environmentally conscious buildings.