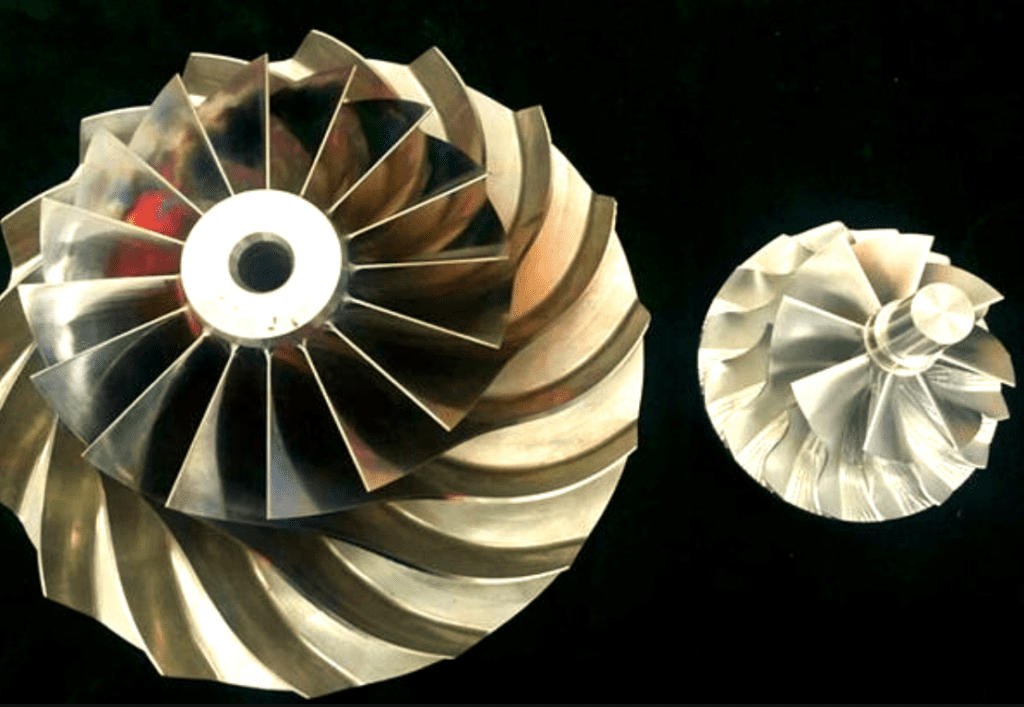

Titanium alloy impellers, renowned for their high strength, low density, corrosion resistance, and excellent high-temperature performance, are critical components in aerospace, energy, chemical, and marine engineering applications, particularly in aircraft engine turbines, gas turbines, and centrifugal pumps. However, the complex geometries of impellers—featuring twisted blades, narrow flow channels, and thin-walled structures—combined with the inherent properties of titanium alloys (e.g., high hardness and low thermal conductivity) make their machining exceptionally challenging. Key difficulties include high cutting forces, severe tool wear, high-temperature sticking, surface quality issues, and stringent precision requirements. This 1500-word article explores these machining challenges in depth, details the essential machining processes and influencing factors, and proposes practical, innovative solutions, emphasizing the pivotal role of five-axis machining technology in enhancing efficiency and precision.

Why Is Titanium Alloy Impeller Machining So Complex?

Titanium alloy impellers, with their intricate designs and superior material properties, are indispensable in high-performance equipment. However, the unique characteristics of titanium alloys—such as high hardness (HRC 32-38), low thermal conductivity (approximately 6.7 W/m·K), high chemical reactivity, and low elastic modulus—render machining significantly more difficult than for common metals. Challenges include elevated cutting forces, rapid tool wear, high-temperature tool sticking, difficulty achieving high surface finish, and the need for micrometer-level precision. The thin-walled blades and non-developable surfaces of impellers further demand advanced equipment and complex tool paths, rendering traditional three-axis machining inadequate.

Five-axis machining technology offers a breakthrough, with its multi-axis linkage enabling precise handling of complex geometries. This article examines the machining difficulties, processes, and influencing factors, proposing solutions through advanced tooling, optimized processes, and five-axis machining to meet the stringent requirements of aerospace and energy industries.

How Do High Hardness And Cutting Forces Impact Impeller Machining?

The high hardness of titanium alloys (e.g., Ti-6Al-4V) generates substantial cutting forces due to significant tangential stresses and plastic deformation during machining. These forces challenge tool durability and machine rigidity, particularly when machining thin-walled impeller blades, where vibrations, tool chipping, or workpiece deformation can occur, compromising flow channel precision and blade performance. In aerospace applications, even minor deviations can reduce turbine efficiency or pose safety risks.

Solutions:

- Advanced Cutting Tools: Use carbide tools with TiAlN, AlCrN, or CVD diamond coatings to enhance wear resistance and high-temperature performance. Polycrystalline diamond (PCD) tools are ideal for finish machining, maintaining sharpness under high hardness.

- Five-Axis Machining: Five-axis machines optimize tool paths by dynamically adjusting angles, reducing cutting forces and vibrations, suitable for complex impeller surfaces and thin-walled structures.

- High-Rigidity Machines: Employ five-axis machining centers with high-torque spindles (>1000 Nm) and stable beds to absorb vibrations, ensuring stability for thin-walled blades.

- Shallow Cutting Strategy: Apply small depths of cut (0.1-0.5 mm) with high feed rates to minimize cutting forces, protecting tools and workpieces.

- Adaptive Control: Use cutting force sensors to adjust feed rates in real-time, balancing loads and reducing vibrations.

How Do High Temperatures And Tool Sticking Exacerbate Machining Challenges?

Titanium alloys’ low thermal conductivity concentrates cutting heat at the tool-workpiece interface, with temperatures exceeding 1000°C. This heat accelerates tool wear and causes tool sticking, where titanium chips adhere to the tool, forming built-up edges that reduce cutting efficiency, surface quality, and tool life. For impeller machining, high temperatures can deform thin-walled blades, distort flow channels, and induce microcracks, compromising fatigue performance in aerospace applications.

Solutions:

- Efficient Coolants: Use high-pressure (70-100 bar) mineral oils, synthetic fluids, or water-based emulsions, delivered directly to the cutting zone, to dissipate heat and reduce sticking. Cryogenic cooling (e.g., liquid nitrogen or CO₂) further controls temperatures for high-precision aerospace impellers.

- Five-Axis Optimization: Five-axis machines minimize heat accumulation by reducing tool dwell time in high-temperature zones through continuous cutting paths.

- Coated Tools: TiAlN or AlCrN-coated tools resist high-temperature oxidation, reducing sticking and built-up edge formation.

- Low-Speed Cutting: Reduce cutting speeds (30-60 m/min) with high feed rates (0.05-0.15 mm/rev) to control temperatures and minimize deformation.

- Laser-Assisted Machining: Preheat the cutting zone with lasers to soften titanium, reducing cutting forces and heat generation, enhancing efficiency.

How Can Surface Quality AQnd Precision Be Ensured?

Titanium alloy impellers require mirror-like surface finishes (Ra 0.1-0.4) and micrometer-level precision to optimize fluid efficiency, corrosion resistance, and fatigue life. However, high temperatures, tool sticking, and wear cause surface scratches, burns, and roughness issues. The low rigidity of thin-walled blades also induces vibrations, affecting flow channel geometry, critical for aerospace turbines where defects can lead to aerodynamic losses or stress concentrations.

Solutions:

- Five-Axis Machining: Multi-axis linkage ensures smooth tool paths, minimizing tool marks and achieving high flow channel finish. Dynamic tool adjustments reduce vibrations, protecting thin-walled structures.

- PCD Tools For Finishing: PCD tools maintain sharpness during finish machining, reducing surface tearing and meeting stringent finish requirements.

- High-Precision Inspection: Employ coordinate measuring machines (CMM), laser scanners, and surface roughness testers to verify dimensions, tolerances, and surface quality in real-time.

- Polishing Processes: Post-machining chemical, ultrasonic, or electrochemical polishing removes minor surface defects, enhancing finish and corrosion resistance.

- Vibration Suppression: Use high-rigidity fixtures and damping systems to minimize chatter, ensuring surface and precision stability.

How Does Tool Wear Affect Machining Efficiency?

Titanium alloys’ high hardness and chemical reactivity cause rapid tool wear, particularly in complex impeller geometries, where tools endure high cutting forces, temperatures, and chemical interactions. Wear mechanisms like chipping, abrasive wear, and adhesive wear increase tool replacement frequency, raising costs and degrading surface quality, impacting impeller performance and durability.

Solutions:

- Wear-Resistant Tools: Prioritize carbide or PCD tools with high-temperature coatings (e.g., AlCrN, CVD diamond) to extend tool life.

- Five-Axis Path Optimization: CAM software (e.g., NX, PowerMill) generates interference-free tool paths, reducing tool stress and wear rates.

- Tool Condition Monitoring: Real-time monitoring of cutting forces, vibrations, and temperatures predicts wear, optimizing replacement schedules and minimizing downtime.

- Tool Maintenance: Implement regrinding and recoating to extend tool life, reducing procurement costs.

- Minimum Quantity Lubrication (MQL): Apply MQL to reduce friction and heat, enhancing tool durability, especially in finish machining.

What Are The Key Processes In Titanium Alloy Impeller Machining?

Machining titanium alloy impellers requires a systematic process to address material properties and geometric complexity.

Material Preparation

Select high-quality titanium alloy blanks (e.g., Ti-6Al-4V), using ultrasonic testing to detect internal defects and ensure material integrity.

Rough Machining

Use carbide end mills on a five-axis machining center to remove bulk material. Parameters: cutting speed 40-60 m/min, feed rate 0.1-0.2 mm/rev, depth of cut 1-2 mm. High-pressure mineral oil cooling controls heat.

Semi-Finish Machining

Employ coated carbide tools to refine blade contours and flow channels, with depths of cut reduced to 0.5-1 mm and speeds of 30-50 m/min for improved accuracy.

Finish Machining

Use PCD or CBN tools for high-precision milling, with depths of cut 0.1-0.3 mm and speeds 20-40 m/min, achieving Ra 0.1-0.4 surface finish.

Drilling And Tapping

Use specialized titanium drills and taps for mounting or threaded holes, with low speeds (10-20 m/min) and high-pressure coolant to prevent sticking.

Surface Treatment

Apply chemical or ultrasonic polishing to enhance surface finish and corrosion resistance; shot peening may be used to improve fatigue life.

Quality Inspection

Utilize CMM, laser scanning, and X-ray testing to validate dimensions, tolerances, and internal integrity, ensuring aerospace standards compliance.

Five-Axis Integration

Perform all stages on five-axis machining centers to minimize setups, using CAM software to optimize tool paths for complex flow channels and thin-walled structures.

This process ensures a balance of efficiency, precision, and quality for high-performance impellers.

What Factors Influence Titanium Alloy Impeller Machining?

The quality and efficiency of titanium alloy impeller machining depend on several factors, each requiring careful management:

- Material Properties: High hardness, low thermal conductivity, and chemical reactivity increase cutting forces, heat, and sticking. Solution: Use PCD tools, efficient coolants, and optimized parameters.

- Tool Performance: Tool material and coatings impact wear and surface quality. Selection: TiAlN/AlCrN-coated carbide for roughing, PCD for finishing, with regular maintenance.

- Machine Rigidity: Low-rigidity machines cause vibrations, affecting precision. Solution: High-rigidity five-axis machining centers with high-precision spindles and damping fixtures.

- Process Parameters: Improper cutting speed, feed rate, or depth increases wear or deformation. Optimization: Speeds of 20-60 m/min, feeds of 0.05-0.2 mm/rev, depths of 0.1-1 mm, with adaptive control.

- Cooling System: Inadequate cooling exacerbates heat and sticking. Improvement: High-pressure (70-100 bar) or cryogenic cooling for effective heat dissipation.

- Workpiece Geometry: Thin-walled blades and complex flow channels are prone to deformation and vibrations. Support: Thin-wall wrapping techniques or auxiliary fixtures, paired with five-axis machining.

- Environmental Factors: Dust or temperature fluctuations affect precision. Control: Maintain clean, temperature-controlled workshops.

- Operator Expertise: Skill levels impact parameter settings and quality control. Training: Enhance CAM programming and machine operation proficiency.

Addressing these factors ensures stable, high-quality machining outcomes.

How Do Machine Rigidity And Process Parameters Affect Machining Outcomes?

Titanium alloy impeller machining demands high machine rigidity and precise process parameters. Low-rigidity machines vibrate under high cutting forces, causing blade deformation, surface defects, and precision losses, particularly in thin-walled structures. Inappropriate parameters (e.g., excessive cutting speed) exacerbate tool wear, heat, and roughness.

Solutions:

- High-Rigidity Five-Axis Machines: Use machining centers with high-torque spindles (>1000 Nm) and robust beds to absorb vibrations, ensuring stability for thin-walled blades.

- Optimized Parameters: Set cutting speeds at 20-50 m/min, feed rates at 0.05-0.15 mm/rev, and depths of cut at 0.1-0.5 mm, tailored to impeller geometry and material properties.

- Adaptive Machining: Employ adaptive control systems to adjust parameters based on real-time cutting feedback, optimizing forces and stability.

- Simulation Validation: Use CAM software (e.g., NX, PowerMill) to simulate machining, predicting vibrations and deformations for optimized tool paths and parameters.

- Fixture Design: Implement fixtures with balanced clamping forces to minimize workpiece deformation and enhance precision.

How Can Advanced Technologies Enhance Machining Efficiency And Quality?

Titanium alloy impeller machining benefits from advanced technologies to overcome limitations of traditional three-axis methods, boosting efficiency and quality.

Solutions:

- Five-Axis Machining: Multi-axis linkage reduces setups, machines non-developable surfaces, and ensures flow channel precision, improving efficiency by over 30%.

- Thin-Wall Wrapping Technique: Auxiliary supports reduce vibrations in thin-walled blade machining, enhancing stability for aerospace impellers.

- Laser-Assisted Machining: Laser preheating softens titanium, reducing cutting forces and tool wear, ideal for high-hardness zones.

- Additive Manufacturing Integration: 3D-printed impeller blanks reduce roughing material, paired with five-axis machining for efficient finishing of complex geometries.

- Smart Manufacturing: IoT and big data analytics optimize parameters and predict maintenance, minimizing downtime and enhancing continuity.

- Ultrasonic-Assisted Machining: Ultrasonic tool vibrations reduce cutting forces and sticking, improving surface quality for micro-structures.

Conclusion

Titanium alloy impeller machining faces challenges from high hardness, low thermal conductivity, and complex geometries, resulting in high cutting forces, tool sticking, rapid wear, and surface quality issues. Five-axis machining, with its multi-axis linkage and optimized tool paths, effectively addresses non-developable surfaces and thin-walled structures. Advanced carbide and PCD tools, high-pressure coolants, a structured process (roughing to finishing), and precise inspections ensure quality and efficiency. Thin-wall wrapping, laser-assisted machining, and additive manufacturing further enhance stability and productivity. Material properties, tool performance, machine rigidity, parameters, and environmental factors must be holistically managed. By integrating smart manufacturing and real-time monitoring, manufacturers can achieve high-quality, efficient titanium alloy impeller production for aerospace, energy, and chemical applications, meeting rigorous performance demands.