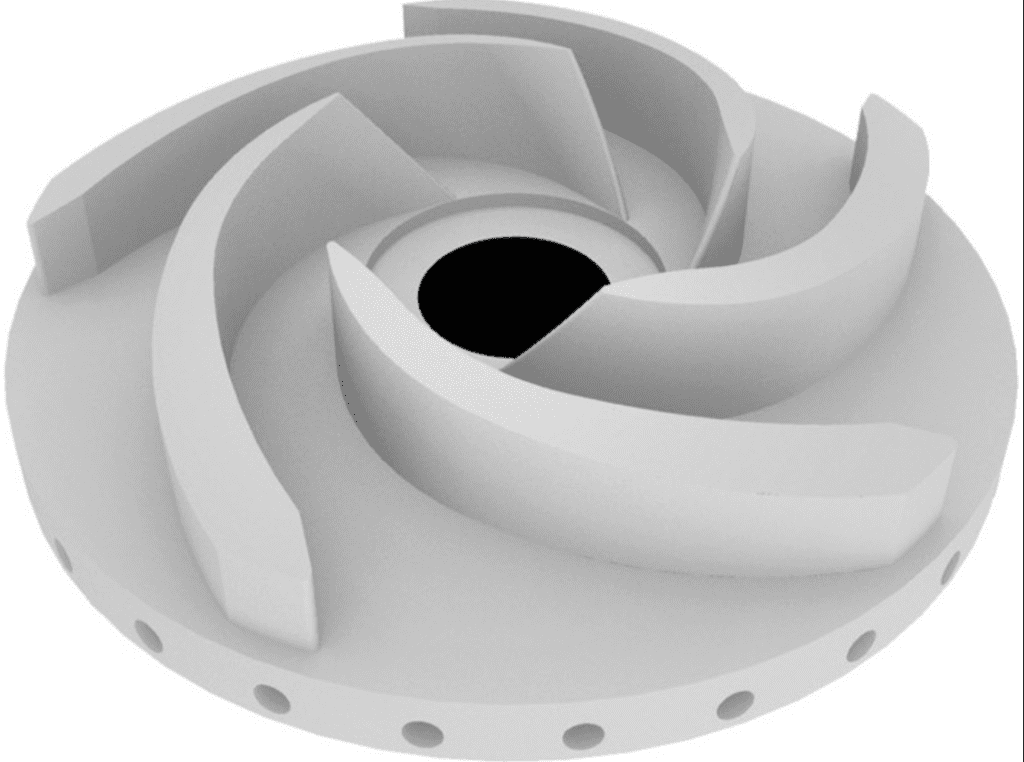

Plastic impellers, valued for their lightweight nature, corrosion resistance, and cost-effectiveness, are widely used in water pumps, fans, automotive cooling systems, and industrial fluid equipment. However, the processing of plastic impellers, particularly through injection molding and extrusion, presents significant challenges due to the complex geometries (such as thin-walled blades and narrow flow channels) and the inherent properties of plastic materials (e.g., varying flowability, thermal sensitivity, and moisture absorption). Common issues include strand breakage, voids, material overflow, bridging, surface defects, and dimensional inaccuracies, often linked to raw material quality, equipment conditions, process parameters, and environmental factors. This 3000-word article delves into these processing difficulties, analyzes their causes, and proposes practical solutions, emphasizing the critical roles of precision injection molding, five-axis CNC post-processing, and intelligent control systems in enhancing efficiency and quality. Optimized for SEO, it features nine reader-focused H2 headings, natural keyword integration, and a structured format to provide actionable insights for engineers, manufacturers, and researchers, ensuring search engine visibility and user engagement.

Why Is Plastic Impeller Processing So Challenging?

Plastic impellers, crafted from materials like polypropylene (PP), acrylonitrile butadiene styrene (ABS), or polyamide (PA), are essential for efficient fluid dynamics in applications such as water pumps, HVAC systems, and automotive cooling. Their intricate geometries—featuring thin-walled blades, curved flow channels, and tight tolerances—require high precision, often at the micrometer level. However, the processing of plastic impellers, primarily through injection molding and extrusion, is fraught with challenges due to the materials’ thermal sensitivity, varying melt flow rates (MFR), and susceptibility to moisture. Common defects include:

- Strand Breakage: Interruptions in material flow during extrusion, leading to production halts and scrap.

- Voids: Internal gas pockets or shrinkage cavities that weaken structural integrity.

- Material Overflow: Uncontrolled material leakage at exhaust ports, increasing waste.

- Bridging: Material blockages in hoppers or feed zones, disrupting continuous production.

- Surface Defects: Scratches, black spots, or roughness from carbonization or impurities.

- Dimensional Deviations: Inaccuracies caused by uneven cooling or insufficient plastification.

These issues stem from factors such as poor raw material quality (e.g., black spots or impurities), equipment wear (e.g., screw damage or clogged exhausts), improper process parameters (e.g., low temperatures or excessive shear), and environmental influences (e.g., humidity). Precision injection molding, five-axis CNC post-processing, and intelligent control systems offer solutions by enabling precise control over complex geometries and material behavior. This article explores these challenges, processes, and influencing factors, proposing advanced strategies to achieve high-quality plastic impeller production.

How Does Strand Breakage Disrupt Processing Efficiency?

Strand breakage, where extruded material strands snap during processing, is a prevalent issue in plastic impeller production, leading to production interruptions, increased scrap rates, and reduced efficiency. This defect is particularly disruptive in extrusion processes for impeller preforms or pellets. The causes are multifaceted:

Raw Material Impurities: External contaminants (e.g., sand or dust) or internal carbonized particles weaken strands, causing breakage under traction forces.

Poor Plastification: Low extrusion temperatures (e.g., <180°C for PP) or insufficient screw shear result in unmelted material clumps, compromising strand integrity.

Exhaust Issues: Trapped gases or moisture in strands, due to inadequate natural or vacuum exhaust, create weak points that fail under tension.

Equipment Factors: Worn screw threads, excessive barrel-screw clearance (>0.5 mm), or rough die surfaces (Ra >0.4) cause material carbonization, further weakening strands.

Process Parameters: Excessive screw speed (>150 rpm) or high die pressure (>15 MPa) induces shear heating, leading to material degradation.

Strand breakage mirrors issues in plastic extrusion, where material consistency is critical for continuous production. Addressing this requires a combination of material, equipment, and process optimizations.

Solutions:

- Material Purification: Pre-screen recycled or crushed materials to remove impurities, use high-mesh filters (100-200 mesh), and seal equipment dead zones to prevent contamination.

- Enhanced Plastification: Increase extrusion temperatures (e.g., 180-230°C for ABS, 240-280°C for PA) and adjust screw speed (50-100 rpm) to ensure complete melting, verified by melt flow tests.

- Improved Exhaust: Regularly clean natural and vacuum exhaust ports (weekly or monthly), maintain vacuum pressure at -0.08 MPa, and ensure seals are intact to remove gases and moisture.

- Equipment Maintenance: Polish die surfaces to Ra 0.4 or better, replace worn screw elements, and eliminate dead zones to prevent carbon buildup, inspected bi-monthly.

- Intelligent Control: Deploy sensors to monitor traction force, die pressure, and temperature in real-time, enabling dynamic adjustments to prevent strand failure.

- Material Drying: Pre-dry hygroscopic materials (e.g., 80-120°C for 4-6 hours for PA) to reduce moisture content (<0.1%), minimizing gas-related breakage.

- Die Design Optimization: Use streamlined dies with taper angles (10-15°) to reduce friction and ensure smooth material flow, validated through flow simulation software (e.g., Moldflow).

These measures ensure robust, continuous production, minimizing downtime and waste.

How Do Voids Compromise Impeller Quality?

Voids, or internal gas pockets and shrinkage holes, are critical defects in plastic impellers, reducing mechanical strength, corrosion resistance, and fluid efficiency. These defects are common in injection-molded or extruded impellers, particularly in thin-walled blades, where material flow and cooling are challenging.

Inadequate Venting: Moisture in raw materials or gas from decomposing additives (e.g., flame retardants) remains trapped due to clogged or inefficient vacuum systems, forming voids.

Poor Plastification: Low processing temperatures (<180°C for PP, <240°C for PA) or weak screw shear (<100 s/s) leave unmelted particles, creating micro voids or, in severe cases, strand breakage.

Improper Cooling: Low cooling water temperatures (<50°C) cause rapid material contraction, leading to shrinkage cavities, especially in crystalline polymers like PA.

Additive Overuse: Excessive low-melting-point additives (e.g., plasticizers, >5 wt%) reduce melt cohesion, increasing void formation.

High Shear Rates: Excessive shear (>300°C localized heating) causes material degradation, releasing gases that form voids.

Voids weaken impeller blades, increasing the risk of failure in high-pressure fluid systems, similar to fatigue cracks in mechanical components.

Solutions:

Enhanced Venting: Inspect and clean vacuum systems monthly, ensure vacuum pressure at -0.08 MPa, and replace worn seals to efficiently remove moisture and gases.

Optimized Temperatures: Set barrel temperatures based on material requirements (e.g., 240-260°C for PA66, 190-220°C for PP), verified by melt temperature sensors.

Controlled Cooling: Maintain water temperatures at 50-70°C to minimize thermal gradients, reducing shrinkage, with automated cooling systems for consistency.

Additive Adjustment: Limit low-melting additives to <5 wt%, balancing processability and performance, validated through rheological testing.

Precision Injection Molding: Use servo-controlled machines to adjust injection speed (20-100 mm/s) and holding pressure (10-30 MPa), filling cavities uniformly to eliminate voids.

Screw Maintenance: Ensure screw shear rates (100-200 s/s) and barrel clearance (<0.3 mm) are optimal, inspected quarterly.

Non-Destructive Testing: Employ ultrasonic or X-ray inspection to detect internal voids post-molding, ensuring quality control.

How Do Material Overflow And Bridging Disrupt Production?

Material overflow (leakage at natural or vacuum exhaust ports) and bridging (blockages in hoppers or feed zones) disrupt plastic impeller production, increasing downtime, waste, and maintenance costs. These issues stem from:

- Overflow Causes:

Mismatched feed and host screw speeds (e.g., feed >50 rpm vs. host 100 rpm).

Excessive vacuum suction (>-0.1 MPa) pulling material into exhaust pipes.

High vacuum zone temperatures (>250°C) reducing melt viscosity, causing slippage.

Absence of reverse conveying elements in screw design, failing to reduce pressure.

- Bridging Causes:

Excessive filler content (>30 wt%) or moisture-induced clumping in hoppers.

Low-melting-point additives (e.g., lubricants) softening at high feed zone temperatures (>180°C), causing material to stick to walls.

Poor hopper design with dead zones or high wall friction.

These defects halt production, similar to mold filling issues in casting processes, requiring immediate intervention.

Solutions:

- Overflow Mitigation: Synchronize feed speed (20-50 rpm) with host speed, reduce vacuum suction to -0.08 MPa, incorporate reverse conveying elements, and maintain vacuum zone temperatures at 200-220°C, monitored by thermocouples.

- Bridging Prevention: Add liquid lubricants (e.g., white oil, 0.1-0.5 wt%) to reduce friction, clean hopper dead zones bi-weekly, and lower feed zone temperatures to 150-170°C.

- Equipment Upgrades: Install vibration devices in hoppers to prevent clumping, and redesign hoppers with steeper angles (>60°) for smooth material flow.

- Smart Monitoring: Use level sensors and temperature probes to detect blockages or overflow in real-time, triggering automatic adjustments or alerts.

- Material Pre-Treatment: Dry materials (80-120°C, 4-6 hours) to reduce moisture (<0.1%), preventing clumping, verified by moisture analyzers.

- Screw Design Optimization: Incorporate kneading blocks and reverse elements to enhance material transport, validated through extrusion simulations.

- Regular Maintenance: Inspect screws, hoppers, and exhaust systems monthly to prevent wear or residue buildup.

How Do Raw Material Property Variations Cause Defects?

Variations in raw material properties, such as melt flow rate (MFR), molecular weight, or additive content, lead to defects like phase separation, strand breakage, or surface irregularities in plastic impellers.

- MFR Disparities: Significant MFR differences in blends (e.g., 10 vs. 50 g/10min) cause phase separation, particularly in injection molding, where weak shear fails to homogenize melts, leading to weak interfaces.

- Molecular Weight Increase: Lower MFR indicates higher molecular weight, increasing melt viscosity and causing plastification issues under standard conditions.

- Additive Effects: Excessive low-melting-point additives (e.g., plasticizers, >5 wt%) reduce melt strength, promoting voids or surface defects.

- Moisture Content: Hygroscopic materials (e.g., PA) absorb moisture (>0.2%), forming gas pockets during processing.

These variations disrupt melt consistency, affecting impeller quality and performance.

Solutions:

- Material Selection: Choose blend components with similar MFR (difference <20 g/10min), verified by MFR testing (ASTM D1238).

- Process Adjustment: Increase extrusion temperatures (+10-20°C, e.g., 250°C for high-MW PA) or reduce screw speed (-10-20 rpm) to improve plastification, monitored by melt pressure sensors.

- Formulation Optimization: Limit low-melting additives to <5 wt%, balancing flowability and strength, validated through differential scanning calorimetry (DSC).

- Twin-Screw Extrusion: Use twin-screw extruders with high shear rates (100-200 s/s) to enhance melt mixing, reducing phase separation.

- Inline Rheology Monitoring: Deploy rheometers to measure melt viscosity in real-time, enabling dynamic parameter adjustments.

- Moisture Control: Pre-dry materials (80-120°C, 4-6 hours) to <0.1% moisture, using dehumidifying dryers.

- Batch Consistency: Implement strict supplier quality checks to ensure consistent material properties across lots.

What Are The Key Processes In Plastic Impeller Processing?

Processing plastic impellers involves a structured workflow to address material properties, geometric complexity, and defect prevention, ensuring precision and quality. Below is a detailed process:

Material Preparation: Select high-quality polymers (e.g., PP, ABS, PA66), testing for MFR (10-50 g/10min) and moisture content (<0.1%) using rheometers and moisture analyzers. Pre-dry hygroscopic materials (80-120°C, 4-6 hours).

Compounding

Blend polymers, additives (e.g., flame retardants, <5 wt%), and fillers in twin-screw extruders (shear rate 100-200 s/s, temperature 180-260°C), producing uniform pellets.

Injection Molding

Use servo-controlled machines to mold impellers, with injection speeds (20-100 mm/s), pressures (80-120 MPa), and mold temperatures (50-80°C). Hot-runner molds enhance flow uniformity, reducing waste by 10-15%.

Extrusion

For pellet production or preforms, extrude materials through twin-screw systems (50-100 rpm, 180-250°C), using high-mesh filters (150 mesh) and polished dies (Ra 0.4).

Cooling And Ejection

Apply staged cooling (50-70°C, 10-20 seconds) to minimize shrinkage, followed by robotic ejection to prevent deformation.

Post-Processing

Perform five-axis CNC machining to refine flow channels and correct defects, achieving ±0.01 mm precision. Apply polishing or coatings for enhanced aesthetics.

Quality Inspection

Use CMM, laser scanners, and ultrasonic testing to verify dimensions (±0.05 mm), surface finish (Ra 0.8-1.6), and internal integrity, ensuring compliance with standards (e.g., ISO 5199 for pumps).

Packaging And Storage

Package impellers in moisture-proof materials, storing at 20-25°C and <60% humidity to prevent moisture absorption or degradation.

Process Automation

Integrate IoT sensors and PLCs to monitor temperature, pressure, and material flow, enabling real-time adjustments and defect prevention.

Conclusion

Plastic impeller processing faces challenges from strand breakage, voids, material overflow, bridging, surface defects, and dimensional deviations, driven by raw material variability, poor plastification, inadequate venting, and equipment issues. Precision injection molding and five-axis CNC post-processing address complex geometries and tight tolerances (±0.05 mm). Optimized parameters, enhanced venting, material purification, and equipment maintenance minimize defects. Twin-screw extrusion, hot-runner molds, smart control systems, and additive manufacturing enhance efficiency and quality. By integrating these advanced technologies and managing material properties, process conditions, and environmental factors, manufacturers can produce high-performance plastic impellers for water pumps, fans, and industrial systems, meeting stringent reliability and efficiency demands.