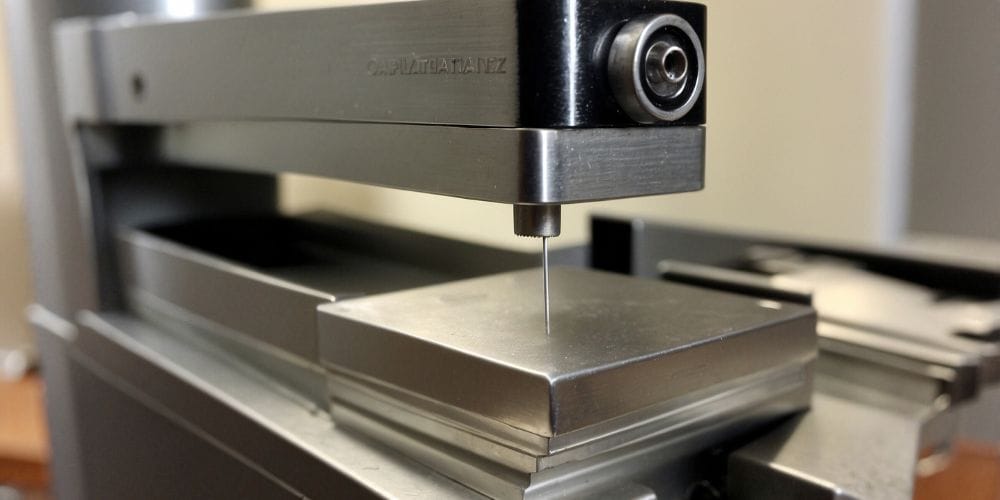

Numerous industries depend on CNC machining for their manufacturing processes. But what exactly is CNC machining? Computer Numerical Control (CNC) is a manufacturing technique that utilizes pre-programmed instructions to control machinery, allowing for the precise production of complex parts and components. The process typically starts with creating a 3D model or 2D design using Computer-Aided Design (CAD) software. This design is then converted into a machine-readable format and uploaded into the CNC machine. Once the machine is set up and the material is secured, the machining process begins, enabling the machine to produce the required parts or components based on the programmed instructions.

In contrast, some manufacturers opt for manual machining tools to create prototype parts. Manual machining remains significant in various industries, particularly for small-batch rapid prototyping.Choosing the right manufacturing technique is crucial for project success. If you’re reading this article, you are likely considering which method to adopt for your project. Continue reading to help you make an informed decision.

Principles Of CNC And Manual Machining

To understand the differences between CNC and manual machining, it’s essential to begin with their working principles.

CNC Machining Principles

CNC machining is an automated process that requires digital files containing cutting and processing instructions. This method relies on various tools to manufacture parts, and engineers and machinists develop a digital tool library to interact effectively with the CNC machines. The process starts with creating 3D models or 2D drawings using Computer-Aided Design (CAD) software. These designs are then converted into G-code, a machine-readable format that defines the machine’s movement trajectory, speed, and feed rate. Based on the CAD model, tool paths are generated, guiding the cutting tools to precisely machine the workpiece.

Manual Machining Principles

Manual machining involves traditional machinery operated by hand. The principle of manual machining is centered on the operator controlling mechanical tools to remove material and manufacture parts. Operators use various hand tools, such as lathes, mills, and drills, to perform operations directly. These tools eliminate excess material from the workpiece through cutting, drilling, or grinding, gradually shaping it to the desired dimensions.

In comparison to CNC machining, manual machining relies significantly on the skill and expertise of the operator, often requiring more time and effort to complete tasks. It is particularly well-suited for producing small batches of parts.

By examining these principles, it becomes clear how CNC and manual machining differ in their operations and applications.

CNC Machining Vs Manual Machining- Advantages And Disadvantages

CNC machining and manual machining are fundamentally different processes, and these distinctions can often be observed through visual inspection of the finished parts or by comparing their production outputs. Below are the advantages and disadvantages of each method, helping clarify what to expect:

Advantages Of CNC Machining

Reliability And Efficiency: CNC machining is computer-controlled, significantly reducing the risk of human error. This automation makes CNC machining a more reliable and faster method compared to manual machining. CNC machines can operate at high speeds, allowing manufacturers to alleviate supply bottlenecks and meet large-scale production demands. In summary, CNC machining provides greater precision and shorter manufacturing times.

Reduced Labor And Maintenance Requirements: CNC machines require fewer experienced operators, as a single skilled technician can oversee production. This minimizes manual handling of products, enhancing safety during the process. With automated systems monitoring operations, the chances of machine malfunctions decrease, resulting in lower maintenance costs. Furthermore, CNC machines require less maintenance than manual machines, even when running continuously, needing only occasional upkeep.

Design Consistency And Safety: CNC machining excels at consistently reproducing the same design, as components can have identical dimensions and programming. This ensures that all parts look uniform, making it ideal for mass production and increasing profitability without raising workload or costs. Additionally, operating CNC machines is safer, as operators are kept at a safe distance, eliminating direct physical interaction with the machinery.

Versatility and Flexibility: CNC machining offers exceptional versatility and flexibility, allowing for quick transitions between different materials and complex geometries. It can create parts from various materials without requiring separate machines or setups, enabling swift changes between different projects. In contrast, manual machining often necessitates reconfiguration and manual adjustments, which can be time-consuming and error-prone.

Disadvantages Of CNC Machining

Despite its advantages, CNC machining has certain drawbacks:

High Initial Investment And Maintenance Costs: The cost of CNC machines is significant. While CNC manufacturing is generally more cost-effective for large volumes over time, the initial investment can be high.

Need For Skilled Programmers: Although CNC processes do not require manual operators, they do require skilled programmers to set up the machines for cutting the desired shapes. While malfunctions are rare, addressing any issues that arise often necessitates the expertise of highly skilled professionals.

Potential For Rising Unemployment Rates: Increased automation can lead to a reduced demand for labor, contributing to rising unemployment rates.

Advantages Of Manual Machining

Manual machining has been practiced for centuries and offers several benefits:

Lower Costs For Small-Scale Production: Manual machining is effective for producing both plastic and metal parts, particularly for small production runs and low-budget projects. The initial investment for manual machinery is comparatively low, making it accessible for small machine shops. For smaller projects or one-time orders, turnaround times are quicker, as there is no need to go through a programming phase.

Simplified Maintenance: Manual machines have simpler mechanisms, making maintenance easier and generally less costly. If a malfunction occurs, repairs for manual mills, for example, tend to be straightforward, leading to lower maintenance expenses.

Disadvantages Of Manual Machining

However, manual machining has its own set of drawbacks:

High Labor Intensity: Manual machining requires more physical effort from operators. Long periods of operation can lead to fatigue and mistakes. Although manual machining can achieve a relatively high level of precision, it remains susceptible to human error.

Low Production Efficiency: Manual machining is typically slower than CNC machining, requiring more time to complete the same volume of work. Tasks that may take just a few minutes with CNC machining can take several hours to complete manually.

By considering these advantages and disadvantages, manufacturers can make informed decisions about which machining method is best suited for their specific needs and projects.

What Is The Main Difference Between CNC And Manual Machining?

The following table outlines the differences between CNC machining and manual machining, highlighting the key distinctions between these two machining techniques.

| Feature | CNC Machining | Manual Machining |

| Control | Controlled by a Computer Numerical Control (CNC) system | Controlled manually by the machinist |

| Automation | Highly automated, relying on computer programming | Completely dependent on operator control |

| Complexity | Especially suited for complex geometries and designs | Suitable for simple tasks; limited in handling complex shapes |

| Setup Time | Initial setup time can be longer, requiring CNC programming | Setup may be quicker but still requires manual adjustments |

| Programming | Requires skills in G-code programming | Machine is manually set and adjusted by the operator, requiring less technical skill |

| Cost | Higher initial investment; cost-effective for large-scale production | Lower initial cost, but less economical for large quantities |

| Delivery Time | Automation results in shorter delivery times | Delivery times may be longer due to manual processes |

| Maintenance | CNC equipment requires regular maintenance | Manual machines are generally easier to maintain |

| Precision | Provides high precision and consistency | Precision depends on the operator’s skill and is susceptible to human error |

| Flexibility | Strong adaptability to materials and designs, allowing for quick adjustments | More flexible, ideal for small batches and custom projects |

Precision And Consistency: CNC machining provides exceptional precision and repeatability. Once a program is established, the machine can consistently manufacture identical parts, significantly reducing variability. In contrast, manual machining is heavily dependent on the operator’s skill and concentration. Human errors can result in inconsistencies, making it challenging to attain the same level of precision as that achieved through CNC machining.

Cost Implications: CNC machining necessitates a higher initial investment due to the expenses associated with CNC machines and software. However, it becomes more cost-effective for large-scale production as it minimizes labor costs and reduces processing time. On the other hand, manual machining equipment comes with a lower initial cost, making it an attractive option for small workshops. Nonetheless, for large-scale production, costs may escalate due to the labor-intensive nature of the process and the longer processing times involved.

Labor And Skill Requirements: CNC machining requires operators to possess programming skills and a solid understanding of CNC technology. While there is less manual involvement, skilled technicians are still essential for machine setup and troubleshooting. In contrast, manual machining relies predominantly on the expertise and experience of the machinist. Skilled operators are vital for achieving high-quality results, particularly when executing complex tasks.

How To Decide If CNC Or Manual Machining Is Better For Your Needs?

Selecting between CNC machining and manual machining largely depends on your specific needs and production objectives. If your focus is on producing small batches or custom projects with unique items, manual machining might be the more suitable choice. Conversely, for efficient production runs or the creation of high-precision parts, CNC machining stands out as the ideal option.

If the substantial initial investment required for CNC machines poses a challenge, consider utilizing CNC machining services from Ultirapid as a viable alternative. At Ultirapid, we provide subcontract machining services that mitigate the risks and complexities associated with CNC technology. With our state-of-the-art tools and the expertise of our skilled programmers, you can reap the benefits of CNC machining without the burden of significant upfront costs or risks.

Conclusion

This is just a simple comparison between CNC machining and manual machining. It is unrealistic to expect manual machining to deliver the same results as CNC machining. CNC machining, controlled by CAD and CAM software, offers accuracy, precision, and safety, enabling efficiency and higher production volumes at lower costs. Most importantly, it provides safety measures that manual machining cannot match.

Final Thoughts

As a professional with 15 years of experience in CNC machining service, I’ve come to understand the significant differences between CNC and manual machining.CNC machining utilizes computer programs to control machinery, ensuring high precision and consistency, which is ideal for mass-producing complex parts. For example, in previous aerospace projects I’ve worked on, CNC technology enabled us to produce components that met stringent standards, significantly improving efficiency and accuracy. In contrast, manual machining relies on the skill of the operator. While it allows for flexible customization, it often falls short in terms of precision and production speed.From my experience, CNC machining allows for easy repetition of tasks while minimizing human error. However, for small batches or specialized projects, manual machining still holds its unique value. Overall, the choice between methods depends on project requirements, but CNC machining clearly offers more advantages in modern manufacturing.I highly recommend UtiRapid as an efficient CNC machining service platform that provides fast and precise solutions for your projects.

FAQS

How Does The Skill Set Of A Manual Machinist Differ From That Of A CNC Machinist?

The skill set of a manual machinist primarily involves hands-on experience with traditional machining tools, requiring strong manual dexterity, mechanical aptitude, and the ability to make quick adjustments based on visual inspection. In contrast, a CNC machinist needs proficiency in programming and operating CNC machines, including knowledge of CAD/CAM software, technical drawing interpretation, and the ability to troubleshoot software and machine issues.

Can Manual Machines Perform The Same Tasks As CNC Machines?

Manual machines can perform many of the same tasks as CNC machines, such as milling and turning. However, CNC machines offer higher precision, automation, and the ability to handle complex designs and multi-axis operations more efficiently. While manual machines may be quicker for one-off tasks, CNC machines are better suited for high-volume production due to their accuracy and repeatability. Overall, CNC machines generally outperform manual machines for intricate and high-tolerance work.

Are There Any Industries Where Manual Machining Is Still Preferred Over CNC Machining?

Yes, manual machining is preferred in certain industries, especially for:

- Prototype Development: Allows quick adjustments and iterative changes.

- Low-Volume Production: More cost-effective for small batches or one-off parts.

- Tool and Die Making: Offers flexibility for custom tools.

- Repair Work: Suitable for quick modifications and adjustments.

- Artisan and Custom Work: Preferred for bespoke or handcrafted items.

While CNC machining has many advantages, manual machining remains relevant for its flexibility and immediacy in these contexts.

Is CNC More Accurate Than Manual Machining?

Yes, CNC machining is generally more accurate than manual machining. CNC machines can achieve tolerances of ±0.01 mm or better due to their automated processes, which minimize human error. In contrast, manual machining relies on the operator’s skill, leading to variability in accuracy. For high-tolerance and complex parts, CNC machining is the preferred option due to its superior precision and reliability.