In the realm of precision machining, selecting the right CNC milling axes is crucial for enhancing creativity and efficiency. Although 3-axis milling has traditionally been the industry standard, the introduction of 4-axis and 5-axis CNC machines is transforming manufacturing processes, enabling engineers and designers to expand the possibilities of their projects. Imagine producing intricate components with exceptional accuracy while simultaneously minimizing setup time and boosting productivity. As we examine the distinctions between these milling techniques, you’ll see how each additional axis introduces a new dimension to the manufacturing process, reshaping our approach to complex designs and innovations. Prepare to explore the forefront of CNC milling technology!

Differences Between 3-axis, 4-axis, And 5-axis CNC

3-axis, 4-axis, and 5-axis CNC machining differ significantly in various aspects, including the number of axes, machining capabilities, precision, and application range.

Number Of Axes:3-axis CNC machines operate with three linear movement axes (X, Y, and Z). In contrast, 4-axis CNC machines add one rotational axis (commonly the A-axis), while 5-axis CNC machines incorporate two additional rotational axes (A and B), providing enhanced flexibility for complex machining tasks.

Complexity Of Machining:3-axis machining is suitable for simple geometries and basic contours, often requiring multiple setups. On the other hand, 4-axis machining can handle parts with angled surfaces and complex features, minimizing the need for re-fixturing. Meanwhile, 5-axis machining excels at producing highly intricate shapes in a single setup, making it ideal for 3D surfaces and detailed molds.

Production Efficiency:3-axis machining generally has lower efficiency due to frequent fixture changes and repositioning of workpieces. In comparison, 4-axis machining enhances efficiency by reducing the number of setups needed for continuous multi-surface machining. 5-axis machining achieves the highest efficiency by completing multiple surfaces in one setup, significantly shortening production cycles.

Precision And Surface Quality:3-axis machining provides lower precision, making it suitable for simpler parts. In contrast, 4-axis machining increases precision, particularly for angled surfaces and complex geometries. 5-axis machining offers the highest level of precision and surface quality, meeting the demands of high-end manufacturing.

Material Compatibility:3-axis machines are typically suited for softer materials such as plastics and aluminum. 4-axis machines can handle moderately hard materials like steel and aluminum alloys, while 5-axis machines are capable of machining high-strength materials such as titanium alloys and composites, making them suitable for aerospace applications.

Programming Complexity:Programming for 3-axis machines is relatively simple and user-friendly, while 4-axis programming is slightly more complex, requiring attention to rotational axis movements. In contrast, 5-axis programming is the most complex, necessitating a deep understanding of 3D coordinate systems and cutting paths, but it allows for greater machining flexibility.

Equipment Cost:3-axis machines are generally the least expensive, making them suitable for startups and small-scale production. 4-axis machines have a moderate cost and are well-suited for medium-sized enterprises, offering greater flexibility. In contrast, 5-axis machines are the most expensive and are ideal for large manufacturing firms, particularly in high-precision and complex machining fields.

Operator Skill Requirements:3-axis machining requires lower skill levels, making it suitable for beginners. In contrast, 4-axis machining necessitates some operational experience and understanding of rotational axis control. Finally, 5-axis machining demands high skill and experience from operators capable of handling complex machining tasks.

What Is A 3-axis CNC?

3-axis CNC machines represent the most fundamental type of CNC equipment. A 3-axis CNC (Computer Numerical Control) machine operates by controlling the movement of the tool along three linear axes: X (left-right), Y (forward-backward), and Z (up-down). Operators input machining instructions using G-code, which directs the machine to move the tool precisely, enabling it to perform cutting, milling, or drilling on the material.

These machines feature a straightforward structure and are user-friendly, making them ideal for beginners. Key characteristics include easy programming, versatility in handling various machining tasks (such as milling and drilling), and efficiency in processing simple geometries. Their relatively low cost contributes to their popularity among small businesses and startups.

The advantages of 3-axis CNC machines include lower costs, ease of operator training, and their effectiveness in machining simple parts. However, they do have limitations in flexibility; they can typically only machine one side of a complex part at a time, necessitating multiple setups. Additionally, their precision may fall short for high-precision or intricate shapes, which can lead to relatively lower production efficiency.

What Is 4-Axis Machining?

4-axis machining builds upon traditional 3-axis CNC technology by introducing a rotational axis, commonly known as the A-axis, which allows the machine to rotate the workpiece during cutting operations. In this setup, the X and Y axes control horizontal and front-back movements, the Z axis manages vertical movement, and the A axis facilitates rotation around a fixed axis. This integration enables the machine to perform machining at multiple angles, enhancing its capability to handle complex geometries while minimizing the need for multiple setups.

4-axis CNC machines are particularly adept at processing inclined surfaces and intricate shapes, which significantly increases their machining flexibility. They can complete multi-surface machining in a single setup, a critical advantage for components requiring precise detailing. Although programming is somewhat more complex than that of 3-axis machines, the user interfaces are typically designed to be intuitive, making it easier for operators to adapt. Additionally, 4-axis machines often feature increased power and cutting capabilities, allowing them to work with a broader range of materials, including metals and plastics.

The advantages of 4-axis machining include enhanced production efficiency, a reduced need for re-fixturing, and the ability to machine complex parts in a single setup, streamlining the production process. However, there are also significant disadvantages, such as higher equipment costs and increased programming complexity, which necessitate a certain level of technical expertise from operators. Furthermore, while 4-axis machines offer improved flexibility, they may still fall short of the capabilities of 5-axis machines for extremely intricate geometries, so it is essential to carefully evaluate specific application requirements when making a selection.

What Is 5-axis CNC Machining?

5-axis CNC machining represents an advanced level of computer numerical control technology that employs five independent motion axes to cut and machine workpieces. These axes include three linear axes (X, Y, Z) and two rotational axes (commonly designated as the A and B axes). This configuration allows the tool to move freely in multiple dimensions, enabling simultaneous machining on various surfaces. As a result, 5-axis machines can create complex shapes in a single setup, improving precision and minimizing the need for workpiece re-fixturing.

The main features of 5-axis CNC machines are their high flexibility and precision. They excel at handling intricate geometries and detailed surfaces, making them well-suited for industries such as aerospace, medical, and mold manufacturing. By enabling cutting at various angles, 5-axis machining reduces the length of cutting paths, enhancing overall efficiency. Additionally, modern 5-axis machines are often equipped with advanced control systems and high-performance servo motors, ensuring stability and accuracy throughout the machining process. Many of these machines also support high speeds and precision, allowing for the processing of a diverse range of materials.

The advantages of 5-axis machining include significantly improved efficiency and precision, as it reduces the time required for multiple setups and enables the machining of complex parts in a single clamping. It also extends tool longevity, decreases cutting forces, and minimizes the risk of workpiece deformation. However, there are drawbacks to consider, such as higher equipment costs and increased programming complexity, which necessitate operators to have advanced skills. Furthermore, for simpler parts, utilizing a 5-axis machine may not be cost-effective, making it essential to conduct a thorough assessment of actual needs when selecting the appropriate equipment.

How To Choose Between 3-axis, 4-axis, And 5-axis Machines?

Selecting the appropriate machine—whether a 3-axis, 4-axis, or 5-axis—depends on several critical factors:

Complexity Of Parts: 3-axis machines are best suited for simple geometries and basic contours. In contrast, 4-axis machines handle parts with angled surfaces or moderate complexity, while 5-axis machines are designed for highly intricate shapes and 3D surfaces.

Production Volume: For low to medium production runs, 3-axis machines are cost-effective. 4-axis machines are more appropriate for medium-sized batches that require some complexity, and 5-axis machines excel in high-volume production of complex parts, significantly minimizing the need for multiple setups.

Precision Requirements: 3-axis machines are sufficient for lower precision tasks. However, 4-axis machines provide increased precision for angled features, and 5-axis machines offer the highest level of precision and surface quality, making them ideal for demanding applications.

Material Types: 3-axis machines work effectively with softer materials like plastics and aluminum. In contrast, 4-axis machines can handle moderately hard materials such as aluminum alloys and steel, while 5-axis machines are capable of machining high-strength materials like titanium and composites.

Budget And Costs: Generally, 3-axis machines are the most affordable option, making them accessible for many businesses. 4-axis machines require a moderate investment due to their increased capabilities, while 5-axis machines represent the highest cost but come equipped with advanced features and efficiencies.

Operator Skill Level: Operating 3-axis machines requires lower skill levels, making them suitable for beginners. In contrast, 4-axis machines demand some operational experience and a basic understanding of rotational axes. Finally, 5-axis machines require advanced skills and expertise in 3D coordinate systems and programming.

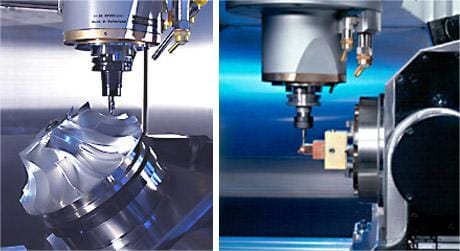

After considering these factors, you might still feel uncertain about making the best choice. To illustrate, let’s look at a part we frequently work with at Ultirapid: the turbine blade. This component is high-precision and complex, featuring intricate geometries, strict accuracy requirements, and specialized machining needs, all of which necessitate the use of a 5-axis CNC machine. In high-tech industries like aerospace, the requirements for 5-axis equipment are particularly stringent. For such applications, we often utilize renowned 5-axis CNC machines, like those from Mazak, to ensure the highest quality machining outcomes.

Conclusion

In the ever-evolving world of CNC milling, the choice between 3, 4, and 5-axis machines can significantly impact your production journey. Each option brings its own strengths to the table, catering to different needs and complexities. So, what will it be for you? Are you ready to elevate your machining game? Share your thoughts and experiences below, and let’s explore the possibilities together!

Final Thoughts

In the rapidly advancing field of CNC milling, selecting between 3-axis, 4-axis, and 5-axis machines can significantly influence your production process. Each option offers unique advantages tailored to specific needs and levels of complexity.

3-axis machines are ideal for simple parts and are often more cost-effective, making them a great choice for straightforward machining tasks. However, if your projects require more intricate designs and greater versatility, 4-axis machines introduce the ability to rotate around one additional axis, enabling more complex geometries and deeper cuts. For the highest level of precision and flexibility, 5-axis machines allow for simultaneous movement across all axes, significantly enhancing production efficiency and accuracy for intricate components.

Are you prepared to take your machining capabilities to the next level? At UtiRapid, we provide a range of advanced CNC milling solutions tailored to your specific needs. We invite you to share your insights and experiences in the comments below, and let’s explore the possibilities together!

FAQS

What Are The Advantages Of The 4th And 5th Axis?

The advantages of the 4th and 5th axes include increased machining flexibility, the ability to work on complex geometries without multiple setups, improved precision for angled surfaces, and reduced cycle times, leading to greater efficiency in production.

What Are The Advantages Of 5 Axis Machining?

The advantages of 5-axis machining include the ability to create complex shapes in a single setup, enhanced precision and surface quality, reduced machining time, improved tool life due to better cutting angles, and the capability to work with a wider range of materials.

What Are The Differences Between 3 Axis And 4 Axis CNC?

The differences between 3-axis and 4-axis CNC machines lie in their movement capabilities: 3-axis machines operate with three linear axes (X, Y, Z) for basic machining, while 4-axis machines add a rotational axis (usually the A-axis), allowing for more complex geometries and angled surfaces without the need for multiple setups.

What Is The Difference Between 5-axis And 6-axis?

The difference between 5-axis and 6-axis CNC machines is that 5-axis machines have three linear axes and two rotational axes, enabling complex shapes and efficient machining, while 6-axis machines add an additional rotational axis, providing even greater flexibility and the ability to handle more intricate geometries and movements.