Water pumps are indispensable in industrial production, agriculture, and urban water supply, with the impeller serving as their core component, directly influencing performance and efficiency. Impellers are categorized into open, closed, and semi-open (or semi-closed) types, each with distinct structural designs, manufacturing complexities, costs, and efficiencies tailored to specific operating conditions and fluid media. The advent of five-axis machining technology has revolutionized impeller manufacturing, enabling high-precision production of complex geometries, particularly for high-performance applications in aerospace, energy, and chemical industries.

What Is An Impeller And Its Role In Water Pumps?

The impeller is the critical rotating component of a water pump, converting mechanical energy from a motor into the kinetic and static pressure energy of the fluid. Found in centrifugal pumps, turbines, and fans, impellers are essential in industries such as industrial manufacturing, agriculture, water treatment, and aerospace. The impeller’s design—whether open, closed, or semi-open—determines the pump’s flow rate, head, and efficiency. Factors like fluid type (e.g., clean water, sewage, or viscous liquids) and operating conditions dictate the choice of impeller type. With the rise of five-axis machining, impellers can now be crafted with unprecedented precision, enabling complex geometries and high-performance applications. This section sets the stage for understanding impeller types and the transformative impact of advanced machining technologies.

Impellers are typically manufactured through casting, welding, or CNC machining, with material selection (e.g., stainless steel, titanium alloys) based on the fluid medium. Five-axis machining, with its ability to handle intricate shapes, has become a game-changer for producing high-precision impellers, particularly for closed and semi-open designs used in demanding environments.

How Do Open, Closed, And Semi-Open Impellers Differ In Structure?

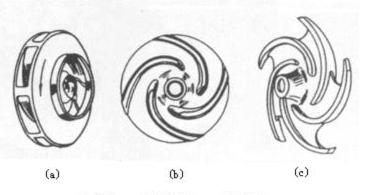

The structural design of an impeller is the primary basis for its classification, with open, closed, and semi-open impellers each offering unique configurations:

- Open Impeller: Comprising only blades and reinforcing ribs without front or back cover plates, open impellers have the simplest structure. The exposed blades facilitate easy manufacturing and cleaning but result in higher fluid leakage, reducing efficiency.

- Closed Impeller: Featuring blades sandwiched between front and back cover plates, closed impellers form enclosed flow channels. This complex structure minimizes fluid leakage, enhancing efficiency but increasing manufacturing challenges.

- Semi-Open Impeller: With blades on one side and a single back cover plate (no front cover), semi-open impellers strike a balance between open and closed designs, offering moderate efficiency and adaptability to various fluids.

In five-axis machining, closed impellers require precise multi-axis control to craft their enclosed flow channels, while open and semi-open impellers are less demanding but still benefit from the technology’s precision for smoother surfaces and tighter tolerances.

How Do Manufacturing Difficulty And Cost Compare Across Impeller Types?

The structural complexity of impellers directly impacts their manufacturing difficulty and cost:

- Open Impeller: With the simplest design, open impellers are the easiest and cheapest to manufacture, often using basic casting or milling processes. Their open structure requires minimal precision, making them ideal for low-budget projects, though they may sacrifice efficiency.

- Closed Impeller: The addition of front and back cover plates increases manufacturing complexity, necessitating advanced techniques like precision casting or five-axis CNC machining. This results in higher costs due to longer production times and the need for high-precision equipment.

- Semi-Open Impeller: Falling between open and closed designs, semi-open impellers have moderate manufacturing difficulty and cost. The single cover plate simplifies some processes, but precision machining is still required to ensure flow channel performance.

Five-axis machining significantly reduces production challenges for closed and semi-open impellers by enabling single-setup machining of complex surfaces, minimizing clamping errors, and lowering post-processing costs, despite the higher initial investment in equipment and programming.

What Are The Efficiency And Performance Differences Among Impeller Types?

The efficiency and performance of a water pump are heavily influenced by the impeller type:

- Open Impeller: These impellers have the lowest efficiency due to significant fluid leakage caused by the absence of cover plates, leading to energy losses. However, their open structure excels in handling fluids with suspended solids or high viscosity, reducing clogging risks.

- Closed Impeller: Offering the highest efficiency, closed impellers minimize fluid leakage through enclosed flow channels, ensuring stable fluid flow and lower axial thrust. They are ideal for clean, low-viscosity fluids like water or solutions in high-performance centrifugal pumps.

- Semi-Open Impeller: With moderate efficiency, semi-open impellers balance fluid control and adaptability, making them suitable for fluids with minor solids or fibers, such as those in chemical pumps.

Five-axis machining enhances the efficiency of closed and semi-open impellers by producing smoother flow channel surfaces, reducing turbulence and energy losses, and ensuring optimal hydraulic performance.

What Are The Suitable Applications For Each Impeller Type?

Each impeller type is designed for specific fluid media and operating conditions:

- Open Impeller: Best suited for fluids with suspended solids, particles, or high viscosity, such as sewage, slurries, or pulp. Commonly used in wastewater treatment or chemical pumps, their open design prevents clogging and simplifies maintenance.

- Closed Impeller: Ideal for clean, low-viscosity fluids like water or solutions, closed impellers are prevalent in industrial circulation pumps, urban water supply systems, and power plant pumps due to their high efficiency and stability.

- Semi-Open Impeller: Versatile for fluids with small amounts of solids or fibers, such as those in refinery or chemical pumps handling near-clean water. Their adaptability makes them increasingly popular in industrial applications.

Five-axis machining is particularly advantageous for closed impellers in high-precision applications, such as aerospace or energy pumps, where smooth flow channels and tight tolerances are critical for performance under demanding conditions.

How Does Five-Axis Machining Enhance Impeller Manufacturing?

Five-axis machining, with its ability to control three linear axes (X, Y, Z) and two rotational axes, is a transformative technology for impeller manufacturing, especially for closed and semi-open designs.

High Precision

Five-axis linkage ensures precise tool paths, achieving tight tolerances critical for closed impeller flow channels, reducing machining errors to meet stringent performance standards.

Complex Geometry Handling

The technology excels at machining non-developable surfaces and narrow flow channels, enabling the production of intricate closed and semi-open impellers with consistent quality.

Reduced Clamping

Single-setup machining minimizes clamping errors and setup times, improving efficiency and reducing production costs for complex impellers.

Superior Surface Finish

Optimized tool paths and cutting parameters produce smoother flow channel surfaces, enhancing fluid dynamics and pump efficiency.

By integrating advanced CAM software (e.g., NX, PowerMill), five-axis machining generates interference-free tool paths, preventing tool collisions with impeller blades, ensuring high-quality production for demanding applications.

How To Choose The Right Impeller Type And Machining Technology?

Selecting the ideal impeller and machining technology is critical to achieving long-term pump performance, reliability, and cost-efficiency. The right choice depends on fluid properties, system efficiency demands, application environments, and budget constraints. By tailoring impeller design and manufacturing methods, you can optimize system performance and minimize maintenance.

Fluid Characteristics

- Closed Impellers: Ideal for clean, low-viscosity fluids with minimal particulate matter. Their fully enclosed design prevents flow disruptions and ensures high hydraulic efficiency.

- Open & Semi-Open Impellers: Best suited for fluids containing solids, fibers, or high viscosity. The exposed vane design helps reduce clogging and allows easier cleaning and maintenance.

Efficiency Requirements

- High-Efficiency Systems: Closed impellers, combined with five-axis machining, offer exceptional performance due to their precise geometry and tight tolerances—crucial for industrial or high-output pumps.

- Moderate-Efficiency Systems: Semi-open impellers offer a balance between efficiency and solids handling.

- Cost-Sensitive Projects: Open impellers with simpler two- or three-axis machining are suitable when efficiency is not the top priority.

Operating Conditions

- Aerospace & Energy Industries: These sectors require maximum precision, making closed impellers produced with five-axis CNC machining the optimal choice. They provide tight tolerances, minimal imbalance, and superior surface finishes.

- Municipal & Wastewater Applications: These can benefit from open or semi-open impellers machined with simpler tools, as resilience and solids handling outweigh precision.

Cost Considerations

- Open Impellers: Lower manufacturing costs, less material usage, and reduced machining complexity make them ideal for budget-friendly or short-lifecycle applications.

- Closed Impellers With Five-Axis Machining: Higher initial cost due to complex geometry and longer machining times, but often justified by extended lifespan, energy savings, and superior performance.

Conclusion

Open, closed, and semi-open impellers each offer unique advantages tailored to specific applications. Open impellers, with their simple, low-cost design, excel in handling solids-laden or viscous fluids but sacrifice efficiency. Closed impellers provide the highest efficiency for clean fluids, ideal for high-performance centrifugal pumps. Semi-open impellers balance efficiency and adaptability for fluids with minor solids, gaining popularity in chemical applications. Five-axis machining revolutionizes impeller production, particularly for closed and semi-open designs, by delivering high precision, complex geometry handling, and superior surface finishes. By optimizing tool paths and reducing clamping, it enhances efficiency and quality, addressing challenges like tool interference and surface roughness. Selecting the right impeller type and leveraging five-axis machining ensures optimal pump performance, meeting the demands of industries from wastewater treatment to aerospace.