Stainless steel, in its uncomparable corrosion resistance, excellent strength, and awe-inspiring visual appeal, is an anchor material across aerospace, medical, automotive, and other industries. From crafting precise turbine blades, lifesaving surgical instruments, to resilient automotive parts, stainless steel machining transforms raw material into high-performance components through state-of-the-art processes including CNC machining. But its unique properties—tendency to harden when worked, low thermal conductivity, and abrasiveness—pose serious challenges that demand skilled knowledge, equipment, and techniques. This in-depth guide dives into the world of stainless steel machining, examining material types, machining challenges, primary processes, best practices, and diverse applications.

What Is Stainless Steel Machining?

Stainless steel machining is the process of fabricating stainless steel into precise, useful parts using highly advanced techniques such as CNC turning, milling, drilling, or similar specialized procedures. The process is critical in sectors where durability, precision, and resistance to harsh conditions are non-negotiable, including aerospace, medical, automotive, and marine applications. The unique blend of corrosion resistance, strength, and appearance flexibility of stainless steel renders it a material of preference for CNC machining, in which computer-controlled tools move along sophisticated tool paths to yield unparalleled accuracy and repeatability.

The significance of stainless steel machining is its ability to produce parts that perform in hostile conditions with structural integrity and aesthetic appeal preserved. Jet engine turbine blades through surgery implants, machined stainless steel parts comprise modern technology. However, the material’s hardness and work-hardening nature require the machinists to apply special cutting tools, optimized machining conditions, and heavy-duty machines to achieve high-quality output. By maintaining stainless steel machining in-house, manufacturers are able to deliver reliable, high-performance components that meet demanding industry standards.

It begins with selection of the appropriate stainless steel grade, then moves on to selection of the appropriate machining process and equipment. CNC machining, with its ability to achieve complex shapes, is particularly well-suited for stainless steel, enabling the creation of advanced parts with tight tolerances. With industries increasingly searching for lightweight, high-strength, and corrosion-resistant parts, stainless steel machining continues to be at the forefront of advancing technology and quality manufacture.

What Are The Types Of Stainless Steel And Their Machining Characteristics?

Stainless steel is not an homogeneous material but is a complicated collection of alloys with unique properties that influence machining practices. Understanding these types is essential in selecting the appropriate grade and optimizing the machining process. Below is a detailed discussion of the primary stainless steel types and their machining characteristics:

Austenitic Stainless Steel (e.g., 304, 316)

Low-magnetic alloys containing high proportions of chromium and nickel that ensure superior corrosion resistance and are preferred for marine, chemical, and food processing applications. Austenitic series is work-hardening susceptible, however, which subjects the workpiece to greater cutting forces and tool wear. Machinists must employ reduced cutting velocities and heavy-cutting tools to manage this problem.

Ferritic Stainless Steel (e.g., 430)

Ferritic grades are magnetic with strong corrosion resistance and are less hard to machine due to lower work-hardening tendencies. They are commonly used in decorative applications, such as automotive trim, and require less severe cutting conditions.

Martensitic Stainless Steel (e.g., 410, 420)

With moderate corrosion resistance and high strength, these magnetic, heat-treatable alloys find application in such usage as turbine components and cutlery. Hardness may prove to be hard to machine through, requiring hard tools and close control to avoid excessive wear.

Duplex Stainless Steel

With the strength of austenitic and the corrosion resistance of ferritic steels, the duplex grades can offer high strength and excellent corrosion resistance, with applications including oil and gas or marine use. Their toughness demands high-rigidity tools and optimised parameter control.

Precipitation-Hardening Stainless Steel (e.g., 17-4 PH)

These are high strength with good corrosion resistance alloys and are widely applied in aerospace and medical areas. Due to their very complex microstructure, they need sophisticated machining methods and special tools to ensure accuracy.

Every type of stainless steel has specific machining strategies to balance performance, cost, and machinability. Austenitic grades, for instance, might require lower speeds to counteract work hardening, but ferritic grades can be machined using higher speeds. Choosing a suitable grade is the most important starting point in achieving successful results in machining stainless steel.

What Are The Key Material Properties Of Stainless Steel?

Stainless steel’s advantageous properties make it a preferred material to machine but also pose certain challenges that require careful consideration. Listed below are the key material properties that define stainless steel and influence machining:

- Corrosion Resistance: Due to over 10.5% chromium content, there is formation of a passive oxide layer that protects stainless steel against corrosion and rusting, making it ideal for harsh environments like marine, chemical, or food processing applications.

- High Tensile Strength And Strength: With its high tensile strength, stainless steel offers strength in car and aircraft use such as parts or components. While this contributes to increased machining challenges, which require robust tools and machines, it offers strength in load-bearing uses.

- Aesthetic Appeal: With a shiny, even surface finish suitable for exposed parts such as architectural hardware or automobile trim, adding both beauty and form.

- Work Hardening: Stainless steel of most grades, especially the austenitic type, work harden rapidly when machining, increasing cutting forces and tool wear. This necessitates lower speeds and special tools.

- Low Thermal Conductivity: Stainless steel retains heat in the cutting zone due to poor thermal conductivity, leading to the accumulation of heat that could damage tools or affect part quality.

- Toughness And Ductility: Stainless steel’s toughness allows it to deflect energy without cracking, but results in stringy, uncontrolled chips when machined.

These traits make stainless steel a skilled and challenging material to work with, pushing machinists to use creative strategies to bring out the best in it.

What Challenges Are Encountered In Stainless Steel Machining?

Machining stainless steel is a problematic task due to its very material properties. The main difficulties and their implications are mentioned hereafter:

Work Hardening: Austenitic stainless steel is most prone to work hardening, which occurs when the material hardens during machining, further increasing cutting forces and tool stress. This requires decreasing cutting speeds and regular tool checks for accuracy to be maintained.

Tool Wear: The abrasive nature of stainless steel encourages tool wear, especially with high grades like martensitic or duplex steels. Coated carbide tools are required in order to extend tool life and maintain the process effective.

Heat Generation: The low thermal conductivity of stainless steel generates heat concentration in the cutting area, which might destroy tools, cause thermal expansion, or compromise surface integrity. Effective cooling systems are required in order to counteract the issue.

Surface Quality Issues: Work hardening and heat buildup can create rough or irregular surfaces, requiring additional finishing operations to polish surfaces. Tool selection and settings should be suitable for surface quality.

Chip Formation: Stainless steel produces hard, fibrous chips that can clog tools, scratch surfaces, or disrupt machining. Chip-breaking techniques, such as peck drilling or optimized feed rates, must be used to manage chips effectively.

A combination of advanced tools, parameter tuning, and robust machining processes are required to combat these challenges for obtaining high-quality products.

What Are The Key Stainless Steel Machining Processes?

Stainless steel machining involves several processes, each suited for different part geometries and industry demands.

CNC Turning

Well-suited for the manufacture of cylindrical parts such as shafts, fittings, or valve bodies, CNC turning demands careful control of cutting speed and feed rate to regulate heat and work hardening. High-rigidity lathes provide accuracy for stainless steel’s toughness.

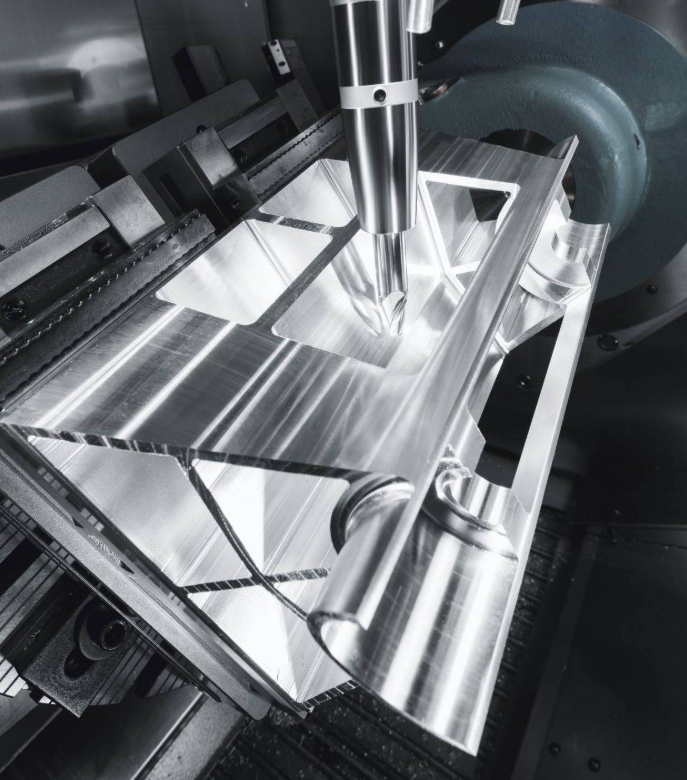

CNC Milling

Most suited for complex geometries such as brackets, housings, or impeller components, milling needs to be performed on heavy-duty machines and equipment to handle the hardness of stainless steel. Five-axis milling allows greater flexibility for intricate shapes and multi-directional machining.

Drilling

Drilling stainless steel is challenging due to heat generation and chip removal issues. Peck drilling, where the drill periodically withdraws, helps manage chips and tool breakdown.

Tapping

Creating threads in stainless steel requires the application of dedicated taps and lubricants to counter thread deterioration due to the material’s hardness and work-hardening properties.

Other Processes

Grinding is applied in high-precision finishing, whereas laser cutting or electrical discharge machining (EDM) is used for complicated contours or micro-features. Waterjet cutting is also employed to slice stainless steel without thermal distortion.

Advantages Of Stainless Steel In Machining

Stainless steel is a prominent machining material due to its excellent properties suitable for aerospace, medical, and automotive applications. Its most significant advantage is enhanced corrosion resistance due to a layer of chromium-rich oxide that protects from corrosion, making it ideal for harsh applications like marine and chemical environments. Its durability ensures machined components, such as turbine blades or food-grade connectors, continue to function with little maintenance. In addition, the great strength and hardness of stainless steel allow it to withstand significant mechanical stress, well suited for load-carrying parts like aerospace fittings or automobile parts. However, its hardness and work hardenability are issues in machining, and heavy-duty tools, such as carbide tipped with TiAlN coatings, and optimized tool parameters must be used to effectively manage heat and tool wear.

In addition to its strength, stainless steel offers flexibility and cosmetic appeal, with precise machining of complex shapes and geometries for use in medical device implants or cosmetic architectural application. Its shiny, mirror-finish appearance is aesthetically pleasing, and it may be utilized for automotive trim or household consumer products. For CNC machining, stainless steel can support close tolerances and surface textures, particularly with five-axis machining, but strict cooling and chip management are necessary to counteract its low thermal conductivity. Also, stainless steel is 100% recyclable in accordance with sustainable production, and its biocompatibility makes it very popular in the field of medical devices. All these benefits render stainless steel unavoidable for making long-lasting, high-performance, and aesthetically pleasing components used in various industries.

Are There Any Disadvantages To Stainless steel For Machining?

While stainless steel is appreciated for its corrosion resistance, strength, and applicability across aerospace, medical, and automotive industries, among others, it presents several challenges when it comes to machining. These disadvantages arise from its material properties, which can make the machining process more difficult, increase cost, and require special approaches.

- Work Hardening

- Greater Tool Wear

- Heat Generation

- Surface Quality Problems

Tips To Ease Stainless Steel Machining

Successful machining of stainless steel requires meticulous planning and execution to overcome its own drawbacks.

Correct Tool Selection

Proper tool selection is required in machining stainless steel. Carbide or high-speed steel (HSS) tools with TiN (Titanium Nitride), TiAlN (Titanium Aluminum Nitride), or AlCrN (Aluminum Chromium Nitride) coatings provide significant enhancements to heat resistance and wear properties—key to cutting stainless steel’s hard and hardening nature. Use stainless steel-grade tools with geometries that promote chip breaking and reduce cutting forces, enhancing process stability and tool life.

Optimized Cutting Parameters

Maintenance of cutting speed, feed rate, and depth of cut is essential in machining stainless steel. Lower cutting speeds (e.g., 50–100 m/min) are required in work-hardening austenitic grades, but ferritic grades allow higher speeds (e.g., 100–150 m/min). Reducing feed and depth of cut avoid excessive heat generation and improve tool life. In addition, climb milling should be employed to reduce fluctuations in cutting forces and improve surface finish, especially for finishing cuts.

Efficient Cooling And Lubrication

Machining of stainless steel generates high temperatures and thus efficient cooling is necessary. Efficient heat removal and chip evacuation are facilitated by high-pressure coolant systems. General machining is possible with water-based coolants, whereas tapping under heavy loads can be performed with oil-based coolants. Uniform flow of coolant prevents thermal shock for the enhancement of thermal stability as well as tool life extension.

Rigidity of Machine And Fixturing

Machine tool and fixturing rigidity are critical to precision and surface finish. Employ high-rigidity CNC machines to reduce vibration and tool deflection. Use stiff, well-designed fixtures to hold the workpiece in place during machining. This is particularly critical on thin-walled or long parts, where bad fixturing will distort the part or cause chatter.

Process Monitoring And Tool Maintenance

Continual monitoring of machine operation and tool condition are necessary in order to provide quality. Check tools regularly for wear, such as edge bluntness or chipping, and replace them promptly. Check for overheating, vibration, or surface imperfections, and alter cutting conditions accordingly. Preventive tool maintenance and continual monitoring optimize tool life, improve process stability, and reduce downtime.

What Are The Applications Of Stainless Steel Machining?

The versatility and strength of stainless steel make it inescapable across most industries, with machine parts playing critical functions in aggressive applications.

Aerospace

Stainless steel is used for accuracy parts like turbine blades, engine fittings, and structural elements in which high strength, corrosion resistance, and light weight are needed. Machined parts must meet stringent safety and performance standards.

Medical Equipment

Surgical instruments, orthopedic implants, and diagnostic equipment rely on the corrosion resistance, biocompatibility, and precision of stainless steel. Machining offers tight tolerances for mission-critical applications.

Motor Vehicle Industry

Engine components, exhaust systems, and trim are improved by the form and strength of stainless steel. Machined parts resist heat and corrosive exhaust gases.

Food And Beverage Industry

Hygienic equipment, such as valves, pumps, and piping systems, capitalizes on stainless steel’s corrosion resistance and ease of cleanliness to deliver high standards of cleanliness.

Marine Applications

Marine hardware, offshore platform components, and ship parts use stainless steel to survive corrosive seawater environments and provide reliability and durability.

Chemical And Oil & Gas Industries

Stainless steel components like reactor vessels, pipes, and fittings are machined to process aggressive chemicals and corrosive environments.

Architectural And Construction

Fittings, structural supports, and decorative panels utilize the strength and beauty of stainless steel for functional and aesthetic purposes.

Conclusion

Machining of stainless steel is a fundamental cornerstone of modern manufacturing, enabling the production of high-performance, corrosion-resistant components that propel industries from medicine to aerospace and beyond. Its unique characteristics—unparalleled strength, corrosion resistance, and beauty, aesthetic versatility—make it a material of choice, but problems like tool wear, work hardening, and heat generation call for innovative solutions. By selecting the proper tools, decreasing cutting parameters, employing effective cooling, and supplying machine rigidity, machinists are able to overcome these issues to make higher-quality parts. As long as industries continue to need lightweight yet strong, precision-machined parts, stainless steel machining will remain on the cutting edge of technology due to advancements in CNC equipment, smart manufacturing, and automation. This guide equips experts with the knowledge to excel in stainless steel machining, bringing forth efficiency, quality, and innovation in manufacturing.

FAQS

What is the Cheapest Stainless Steel for Machining?

For cost-effective stainless steel machining, Grade 409 and 430F are the cheapest due to low alloy content and good machinability, ideal for non-corrosive applications. Grade 303 is a cost-effective austenitic option for precision parts, balancing machinability and moderate corrosion resistance. Always consider project requirements, as cheaper materials may require careful machining to maintain quality.