In today’s landscape of high-precision manufacturing, CNC grooving has emerged as a crucial technology, celebrated for its exceptional flexibility and accuracy. This technique is instrumental in producing fine connection grooves for automotive components and intricate sealing features for aerospace parts, significantly enhancing both the functionality and quality of these products. CNC grooving leverages not only cutting-edge CNC technology but also a smart integration of specialized tools and methods.

This article aims to provide a comprehensive overview of CNC grooving, covering its definition, the necessary tools, the various types, and the detailed processes involved. By examining these aspects, you will gain insight into the technical sophistication of CNC grooving and its vital role in various sectors of the manufacturing industry. Are you prepared to explore this intriguing field? Let’s embark on this journey together!

What Is Grooving?

Grooving is a fundamental machining process that involves creating a precise groove or channel in a workpiece, typically using a specialized cutting tool. This technique can be likened to delicately etching a line on a canvas, enabling manufacturers to produce features that enhance functionality, such as slots for retaining rings or grooves for seals. Its versatility allows grooving to be applied to a wide range of materials, from robust metals to flexible plastics, making it an invaluable method in the manufacturing arsenal.

The precision offered by CNC technology elevates grooving to an art form, facilitating intricate designs and tight tolerances essential in industries such as automotive, aerospace, and medical devices. Various methods can be employed to achieve grooving, including turning, milling, and the use of dedicated grooving tools. Each method presents its own advantages tailored to the specific requirements of the project, whether regarding groove depth or desired surface finish.

Selecting the right tools and cutting parameters is crucial to ensure that the final product not only meets functional specifications but also exhibits a polished appearance. As industries continue to evolve and the demand for precision increases, grooving remains a key process in the production of high-quality components, exemplifying the seamless integration of technology and craftsmanship in modern manufacturing.

Types Of Grooving Tools

Grooving tools are available in a variety of types, each tailored for specific applications and materials. Here is a brief overview of the different types of groove-cutting tools:

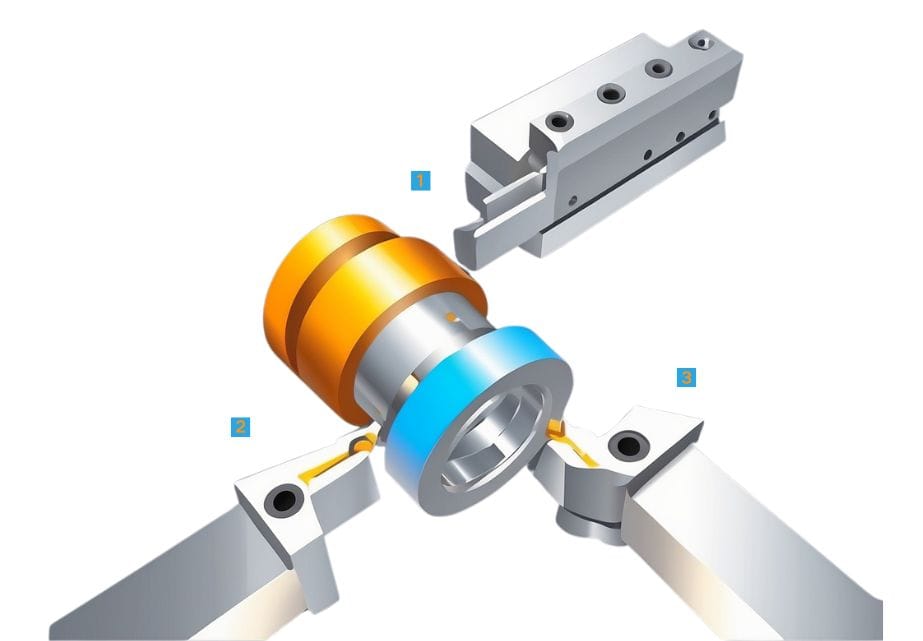

Face Grooving Tools: These tools are essential for creating precise grooves on the surface of a workpiece. They are commonly used in machining applications such as flanges, collars, and various fittings. Featuring a flat cutting edge, face grooving tools slice smoothly across the material’s surface, resulting in clean, well-defined grooves. Their design prioritizes stability and accuracy, enabling them to work effectively with a range of materials, including metals and plastics. This versatility makes them invaluable in industries such as automotive and aerospace, where precise fitting and assembly are critical for performance and reliability.

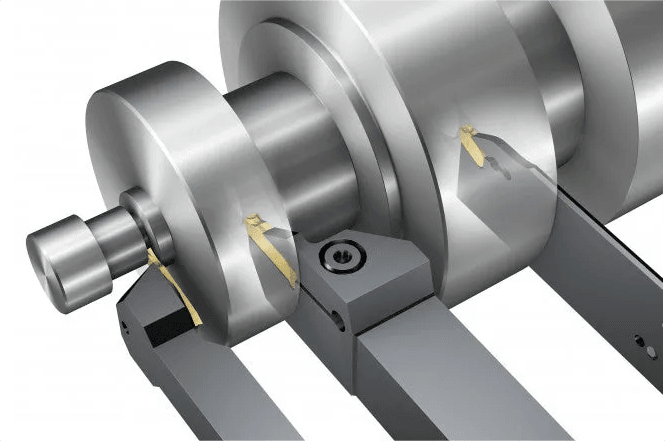

Outer Diameter Grooving Tools: Designed specifically for creating grooves on the outer surface of cylindrical workpieces, outer diameter grooving tools are essential in turning applications. They facilitate the formation of grooves for O-rings, snap rings, or decorative designs. Equipped with sharp cutting edges and a variety of profiles, these tools can efficiently handle different materials while ensuring clean and accurate results. Their capability to operate at high speeds while maintaining dimensional accuracy makes them indispensable in precision engineering industries, particularly automotive and aerospace.

How To Groove On A CNC Lathe?

Grooving on a CNC lathe is a precise machining process used to create grooves or channels in cylindrical workpieces, which are crucial for applications such as fitting seals or adding decorative features. Here’s a step-by-step guide to effectively perform this operation:

Preparation: Start by selecting the appropriate workpiece and securely mounting it in the lathe’s chuck. Ensure the workpiece is properly aligned to prevent inaccuracies during the grooving process.

Tool Selection: Choose a grooving tool that matches the desired groove dimensions, including both width and depth. Grooving tools come in various shapes and sizes, so ensure the selected tool is sharp and appropriate for the material you are working with, whether it’s metal, plastic, or composite.

Programming The CNC: Input the necessary parameters into the CNC control system, including groove specifications such as depth, width, feed rate, and spindle speed. Utilizing CAD/CAM software can streamline this process by generating the appropriate G-code for the machining operation.

Simulation: Before proceeding with actual machining, run a simulation within the CNC software to visualize the tool path and identify any potential issues, such as tool collisions or incorrect settings.

Machining Process: With the lathe operational, initiate the machining process. Start with a slow feed rate to ensure precision and maintain the integrity of the groove. If the initial cuts are successful and the tool is performing well, gradually increase the speed.

Inspection: After completing the groove, carefully measure its dimensions and assess the surface finish. Use calipers or micrometers to verify that the groove meets the specified tolerances. If adjustments are necessary, tweak the parameters in the CNC program and repeat the process.

By following these steps, you can achieve clean and accurate grooves on a CNC lathe, enhancing both the functionality and aesthetic appeal of your machined parts.

Types Of Grooving Methods

Grooving methods can vary based on the type of machining operation, the tools used, and the desired characteristics of the grooves. Here are some common types of grooving methods:

Straight Turning

Straight turning is a fundamental machining process that removes material from the outer diameter of a cylindrical workpiece to create a uniform diameter. Typically performed on a CNC lathe, this operation utilizes a single-point cutting tool that moves along the length of the workpiece. It is essential for producing components such as shafts, pins, and various cylindrical parts that require precise dimensions.

During straight turning, the cutting tool maintains a consistent feed rate while the spindle rotates the workpiece, allowing for efficient material removal and excellent surface finishes. This process accommodates a wide range of materials, including metals, plastics, and composites, making it a versatile choice for diverse manufacturing applications. Additionally, straight turning can be easily programmed and automated in CNC machines, enhancing both production efficiency and accuracy. Overall, straight turning is crucial in precision engineering and is widely utilized across many industries.

Face Grooving

Face grooving is a specialized machining process that creates grooves on the flat surfaces of a workpiece, primarily using a CNC lathe. This operation employs a dedicated cutting tool that moves perpendicular to the surface, enabling precise and clean groove formation. Face grooving is particularly important for applications requiring the installation of seals, O-rings, or decorative designs. The ability to control both the depth and width of the grooves ensures versatility across various materials, including metals, plastics, and composites.

This process not only improves the functionality of components but also enhances their aesthetic appeal. In industries such as automotive and aerospace, where precision is critical, face grooving plays a vital role in ensuring proper fit and performance of parts. With advancements in CNC technology, the automation of face grooving has increased production efficiency and accuracy, making it a vital technique in modern manufacturing practices.

Contour Grooving

Contour grooving is an advanced machining process that creates intricate grooves and profiles on the surfaces of a workpiece, typically using CNC lathes or milling machines. This technique is essential for applications requiring complex shapes, such as contours for seals, gaskets, or decorative designs. The cutting tool is programmed to follow a specific path, allowing for high precision and consistency. The ability to produce varying depths and widths in the grooves adds versatility, making contour grooving suitable for a range of materials, including metals, plastics, and composites.

This process is particularly valuable in industries like automotive and aerospace, where precision engineering is crucial for ensuring optimal fit and functionality. By employing contour grooving, manufacturers can enhance the performance of components while achieving aesthetic appeal. With advancements in CNC technology, the efficiency and accuracy of contour grooving have significantly improved, enabling higher production rates and reducing lead times, ultimately contributing to better overall product quality.

Internal Grooving

Internal grooving is a process specifically designed to create grooves on the inner surfaces of cylindrical workpieces, such as pipes and tubes. This technique is vital for applications that require precise features, such as grooves for seals or bearings. Using specialized cutting tools, internal grooving allows for high accuracy and clean finishes, ensuring that the resulting grooves meet the necessary tolerances. This process is particularly beneficial in industries like oil and gas, automotive, and aerospace, where exact fittings and functionality are essential.

External Grooving

External grooving focuses on creating grooves on the outer surface of cylindrical workpieces, typically performed using a CNC lathe. This method is crucial for applications such as fitting O-rings, creating snap-ring grooves, or adding decorative features. The cutting tool moves parallel to the axis of the workpiece, enabling precise control over groove dimensions. External grooving tools come in various shapes and sizes, allowing manufacturers to achieve specific profiles and depths tailored to their requirements.

The advantages of external grooving extend beyond functionality; they also enhance the aesthetic appeal of components. In industries like automotive and aerospace, where precision and appearance matter, external grooving ensures that parts fit together seamlessly and function optimally. With advancements in CNC technology, external grooving has become increasingly automated, improving both production efficiency and accuracy. This process contributes to the overall performance of components while also meeting stringent industry standards.

Considerations When Choosing A Grooving TooL

Selecting the right grooving tool is crucial for ensuring optimal performance and accuracy in your machining processes. Here are the key factors to consider:

Material Compatibility:Choose a tool that is compatible with the material you are machining, whether it’s metal, plastic, or composite. Different materials may require specific tool coatings or geometries to achieve the best results.

Groove Specifications:Consider the necessary dimensions of the groove, including its width, depth, and profile. The selected tool must be capable of meeting these specifications to ensure proper functionality.

Cutting Edge Geometry:The design of the cutting edge plays a significant role in performance. Look for tools with geometries that promote efficient cutting, effective chip removal, and a good surface finish.

Tool Material:Common materials for grooving tools include high-speed steel (HSS), carbide, and ceramic. Carbide tools are often preferred due to their hardness and wear resistance, particularly in high-production environments.

Application Type:Different grooving applications—such as internal, external, or face grooving—may require specialized tools. Ensure that you select a tool that aligns with your specific application needs.

Machine Compatibility:Confirm that the grooving tool is compatible with your CNC machine or lathe, including considerations for the tool holder and setup requirements.

Cost and Longevity:Evaluate the cost of the tool in relation to its expected lifespan and performance. Investing in higher-quality tools may lead to better efficiency and reduced replacement costs over time.

By thoroughly assessing these factors, you can choose the most suitable grooving tool for your machining requirements, ultimately enhancing the quality and efficiency of your production processes.

Conclusion

CNC grooving is a precision machining technique that employs specialized tools to create various types of grooves on workpieces. By choosing the right tools and methods, manufacturers can improve both efficiency and accuracy, effectively meeting the diverse requirements of different materials and applications.

If you have any additional questions or concerns regarding grooving tools and their applications, please don’t hesitate to contact Ultirapid for expert CNC turning services.

Final Thoughts

CNC grooving is essential in precision manufacturing, providing customized solutions for various industries. As the founder of a company with 15 years of CNC machining service experience, I understand the importance of adapting to different materials and design requirements. Our state-of-the-art equipment features high-quality carbide tools, capable of handling straight, circular, and specialty grooves with precision and consistency. We focus on every detail, ensuring perfection from design to final product. By choosing Ultirapid , you not only receive top-notch grooving services but also benefit from our expert team’s support and insights. We look forward to collaborating with you to achieve outstanding results!

FAQS

What Is The Purpose Of Grooving?

Grooving is used to create narrow channels or grooves in a workpiece for several key purposes. It provides tool clearance for multi-pass operations and reduces overall weight without compromising strength. Additionally, grooving enhances aesthetic appeal with decorative designs, improves the fit of parts in assemblies, such as O-rings, and relieves stress concentrations to enhance durability.

What Type Of Material Is Best For Making Grooving Tools?

The best materials for making grooving tools include:

Cobalt Alloys: Provide additional heat resistance and strength for demanding applications.

High-Speed Steel (HSS): Tough and maintains sharpness at high temperatures, suitable for general use.

Carbide: Offers high wear resistance and durability, ideal for hard materials and longer tool life.

Coated Tools: Coatings like TiN or TiAlN enhance hardness and reduce friction, improving performance.

What Is The Difference Between A Slot And A Groove?

A slot is typically a long, narrow cut or opening in a material, often used for inserting or guiding components, while a groove is a narrow channel or indentation cut into a surface, primarily designed for functional purposes such as securing or guiding.