Flanges are considered critical components in the field of mechanical engineering and pipeline installation in joining two sections of piping. Dimensional accuracy is one of the main attributes concerning its safety and efficiency directly. The article describes in detail the manufacturing processes of flanges, size specifications for various types of flanges, and guidelines for proper selection and usage.

What Is A Flange ?

A flange can be described as a ring-shaped device employed in the connection of items like equipment and pipelines. Though it appears to be a very ordinary device, the position it holds in the industrial production process is very important. Its design and application are directly related to the safety and stability of a mechanical system.

Then, what is a flange? In simple terms, a flange is an annular part used to connect pipes, valves, pumps, and other equipment or components. It is usually fitted with bolt holes that enable tight connections to be achieved between components by the use of fasteners such as bolts and nuts. Indeed, the presence of flanges ensures that complex mechanical systems may work not only stably but also efficiently.

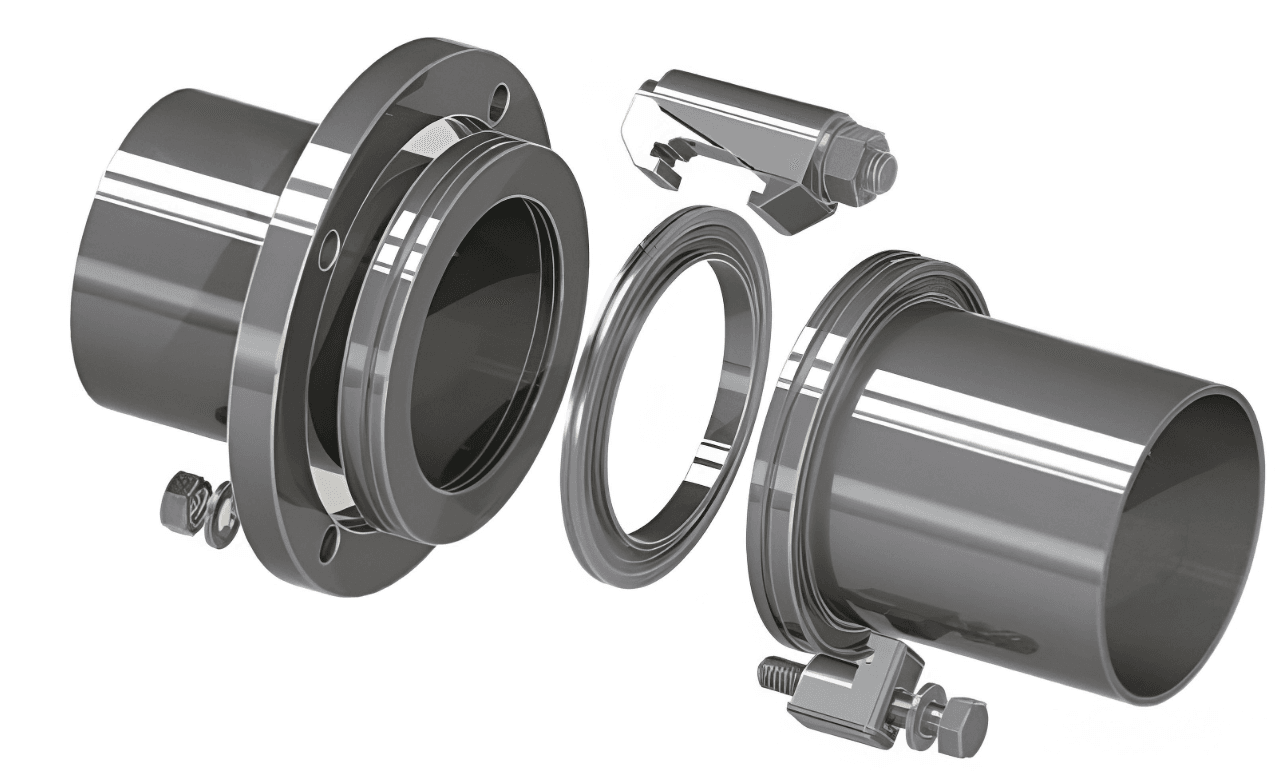

How Do Flange Connections Work?

Sealing is effected by the bolts tightening to compress the gasket. Flange connection leakages are mainly through two paths: gasket leakage and contact surface leakage. Gasket leakage is a situation where fluid passes through the capillaries in the gasket material and is mainly dependent on the material and structure of the gasket. Contact surface leakage is the main cause of sealing failure, occurring at the interface between the gasket and the flange; it is determined by the gap size. Micro-unevenness arises on the flange surface due to mechanical deformation and vibrations during machining; this needs to be filled with a semi-plastic gasket to avoid fluid leakage.

Sealing involves two aspects: initial sealing conditions and operational sealing conditions. Initial sealing depends upon bolt force to compress the gasket/flange surface flat independent of the medium pressure, while in operational sealing, resilience of the gasket is dependent upon maintaining the working sealing pressure above the leakage-driving force due to the pressure differences. If the gasket is not resilient enough, the sealing pressure becomes lower than the working sealing pressure and the gaps at the interface result in seal failure.

Types Of Flanges And Their Main Functions

Flanges come in various types, categorized by their purposes, structures, and connection methods. Below are some common flange types and their primary functions:

Flat Face Flange:Flat face flanges have a flat sealing surface, featuring a simple structure and ease of machining. They are suitable for applications with low pressure and non-toxic media. Sealing is mainly achieved through gaskets between the flanges, making them widely used in low-pressure pipeline connections.

Weld Neck Flange: It is also known as a high-neck flange. The weld neck flange has a high neck that enhances its rigidity and resistance to loads. It is applicable in pipeline connections working under high temperature, high pressure, or low temperature. It is widely used for industrial pipeline systems due to its excellent sealing performance and strong rigidity.

Threaded Flange:The threaded flange is connected with internal and external threads for easy installation and disassembly. It is suited for low-pressure pipeline connections that are subject to frequent disassembly. While the connection is of good quality, the strength of the threads and their sealing capability limit its application, making it unsuitable for high-pressure or high-temperature applications.

Loose Flange:A loose flange includes several parts: a flange sleeve, a flange cover, a sealing gasket, and connecting bolts. It is meant for pipeline systems with sharp changes in the medium temperature or pressure. It enables the adjustment of gasket compression with ease to ensure a good seal. The loose flange has the advantage of adaptability for very complicated working conditions.

There are other forms besides these common types of flanges to suit the various requirements in different applications, such as blind flanges.

Main functions of the flange:

Connection Function: The flange should be used for the connection of pipelines, valves, pumps, and other devices. It accomplishes tight connections between parts by means of bolts or other fastening means to ensure the integrity of mechanical systems.

Sealing Function: Combined with gaskets, the flanges seal effectively at the points of connection and prevent leakage of the media to allow for safe operation of mechanical systems.

Ease Of disassembly For Maintenance: Flange connections, compared with other methods of connection such as welding, make pipeline systems easier to disassemble and perform maintenance, which reduces maintenance time and cost.

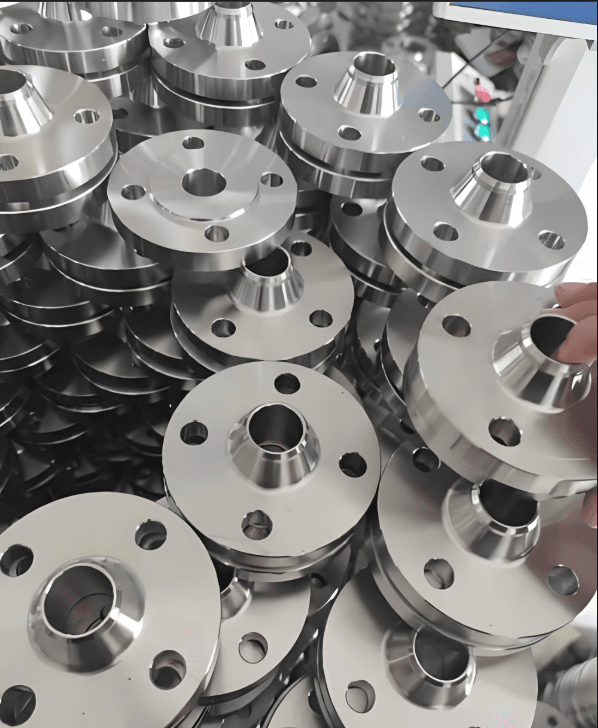

Machining Process Of Flange Parts

The manufacturing process of flanges encompasses various stages, such as material selection, forging or casting, heat treatment, flange machining, and surface treatment.

Material Selection

The operating environment and requirements of the flange determine the choice of appropriate materials such as carbon steel, stainless steel, or alloy steel. Material selection has a direct effect on the mechanical performance and corrosion resistance capacity of the flange.

Forging Or Casting

The method of manufacturing of flange blanks by forging or casting depends on the shape and size of the flange. Forged flanges have higher mechanical performance and better structural density, while cast flanges can be used for more complicated shapes and sizes. Each has advantages, and the choice depends on specific requirements.

Heat Treatment

The flange blank shall undergo heat treatment to remove internal stresses, improve structural performance, and increase mechanical strength. Heat treatment in annealing, normalizing, quenching, and tempering is decided according to the flange material and application.

Flange Machining

It is vital to precisely machine the flange using lathes, milling machines, drilling machines, and other equipment on dimensional accuracy and surface quality. Attention should be focused on tool selection, cutting parameter setting, and processing sequence during machining.

Surface Treatment

Anti-rust coatings, painting, or other surface treatments are applied to the flange for improving corrosion resistance and looking nice. The quality of the surface treatment directly influences the service life and appearance of a flange.

Inspection And Packaging

The finished flanges will go through rigid inspection in terms of dimensional accuracy, surface quality, and mechanical performance. After qualification, the flanges would be packaged and stored appropriately for shipment. Inspection is an important step to assure product quality and therefore cannot be omitted.

Flange Dimensions And Precautions To Ensure Correct Dimensions

Flanges, as a type of connector, are widely used internationally, necessitating unified standards.

European Flange System:

Germany DIN (including the Soviet Union)

- Nominal Pressure: 0.1, 0.25, 0.6, 1.0, 1.6, 2.5, 4.0, 6.4, 10.0, 16.0, 25.0, 32.0, 40.0 MPa;

- Nominal Diameter: 15~600mm;

- Flange Structural Types: Flat-welded plate type,Flat-welded ring loose-sleeve type,Rolled edge loose-sleeve type,Butt-welded rolled edge loose-sleeve type,Butt-welded ring loose-sleeve type,Butt-welded type,Necked-threaded connection type,Integral type,Flange cover;,Flange Sealing Faces:

- Flat:Concave,Convex,Tongue-and-groove,Rubber ring connection,Lens face,Diaphragm welded face

- The Soviet Union’s OCT pipe flange standard, released in 1980, is similar to the German DIN standard.

American Flange System:

The American ANSI B16.5 Standard for Steel Pipe Flanges and Flanged Fittings

- Nominal Pressure: 150psi (2.0MPa), 300psi (5.0MPa), 400psi (6.8MPa), 600psi (10.0MPa), 900psi (15.0MPa), 1500psi (25.0MPa), 2500psi (42.0MPa);

- Nominal Diameter: 6~4000mm;

- Flange Structural Types:Butt weld,Socket weld,Threaded connection,Loose-sleeve,Butt weld,Flange cover;

- Flange Sealing Faces:Concave,Convex,Tongue-and-groove,Metal ring connection.

JIS (Japanese Standard) Pipe Flanges:

JIS pipe flanges are primarily used in petrochemical facilities, typically for utility systems, and have relatively minor influence internationally. They do not form an independent system globally.

Attached To The GB (National Standard) System In China:

- Nominal Pressure: 0.25MPa~42.0MPa

Series 1: PN1.0, PN1.6, PN2.0, PN5.0, PN10.0, PN15.0, PN25.0, PN42 (Main series)

Series 2: PN0.25, PN0.6, PN2.5, PN4.0

Among these, PN0.25, PN0.6, PN1.0, PN1.6, PN2.5, and PN4.0 correspond to the flange dimensions of the European Flange System, which is represented by German standards. The remaining series follow the American Flange System.

The highest nominal pressure level under the European flange system is 4MPa.

- Nominal Diameter:Ranges from 10mm to 4000mm.

- Flange Types:Integral Flange,Unit Flange,Threaded Flange,Welded Flange,Butt-Weld Flange,Neck Butt-Weld Flange,Neck Socket-Weld Flange,Plate Type Butt-Weld Flange,Loose Flange,Butt-Weld Ring-Less Flange with Neck,Butt-Weld Ring-Less Plate Type Flange,Plate Type Loose Flange,Flanged Blind (Plug) Flange,Flange Sealing Surfaces:

- Flat Surface:Concave Surface,Convex Surface,Tongue and Groove Surface,Ring Connection Surface

How to choose the right flange machining methods?

Selecting the right flange machining method requires comprehensive consideration of multiple factors to ensure a balance of machining quality, efficiency, and cost.

Turning

Turning is the most general method of machining outer diameter, inner bore, and end face of round flanges by utilizing CNC lathes in an attempt to gain high precision and concentricity. It suits best for flanges with close tolerances (e.g., ±0.01mm), for example, weld neck high-pressure flanges. Turning may be used for carbon steel and stainless steel, but hard material requires high-performance tooling and low cutting speed. Manual lathes are suitable for small lots, while CNC lathes are recommended for large lots to improve efficiency. When selecting turning, give firm clamping to avoid vibration from affecting accuracy and inspect tool wear frequently to maintain surface quality.

Milling

Milling is utilized for machining complex flange geometries such as grooves, keyways, or non-circular holes on flange surfaces, particularly typical for weld neck or special flanges. CNC milling machines or multi-axis machining centers can easily support complex geometries, with a surface roughness of up to Ra 3.2μm, suitable for non-sealing surfaces. Manual milling is appropriate for small lot sizes, but CNC milling with fixtures is ideal for large lot sizes to achieve maximum efficiency. When milling, utilize appropriate milling cutters by shape and material, and reduce cutting paths to lower machining time and tool wear.

Drilling

Drilling is a specialized process for machining bolt holes in flanges that is used on all forms of flanges to provide hole position accuracy specifications. CNC drilling machines or machining centers permit precise control over hole diameter and position, suitable for applications requiring high precision. Rigid drill bits and coolant are required for deep or large-diameter holes, and carbide bit low-speed drilling is suitable for hard materials. When selecting drilling, use fixtures to secure the flange to prevent misalignment and inspect for drill bit wear at all times to prevent hole size deviation, thus ensuring easy bolt installation.

Grinding

Grinding is utilized for high-precision surface machining, e.g., for flange sealing surfaces, with low roughness and high flatness, which can be used for flanges in high-pressure or high-temperature applications. Grinding achieves close tolerances and is best for hard materials or heat-treated flanges. Grinding is less efficient and is typically used in the finishing process. When choosing grinding, manage the grinding speed to avoid surface burns and use high-precision grinders to meet sealing face quality, fulfilling stringent industry demands.

Post-Forging Machining

Post-forging machining targets forged flanges, with rough and finish machining to remove surface excess and achieve design dimensions. Forged flanges possess high strength and less defect, with rough machining removing large allowances and finish machining ensuring accuracy. High-hardness materials require robust tools and appropriate cutting parameters. Automated production lines enhance efficiency for high production runs. In selecting this method, control machining deformation and inspect surface defects to ensure quality.

Post-Casting Machining

Post-casting machining processes cast flanges to improve their rough surfaces and irregular material properties, requiring rough machining to remove defective layers and finish machining to improve dimensional accuracy and surface quality. Cast flanges are cost-effective, for low-pressure applications, but may be porous, and non-destructive testing is required to adjust machining depth. When choosing this method, condition cutting parameters for material properties without excessive cutting that compromises strength, at the cost of cost and quality.

All these machining operations address particular needs and circumstances: turning and drilling for primary machining, milling and special machining for complicated surfaces, grinding for high-precision surfaces, and post-forging/casting machining to maximize the properties of material. Decision-making will involve factors of flange type, material, precision, batch size, and cost and compliance with industry standards

Conclusion

In recent years, with the advancement of technology, the design and manufacturing of flanges have also been continuously upgraded. Modern flanges are not only more precise in terms of standard sizes, but new breakthroughs have also been achieved in materials and processing techniques. Take a look, for instance: by using advanced welding technologies together with heat treatment processes, one can now make stronger and more resistant-to-corrosion flanges enable them to work stably under various harsh environments.

In addition, the flange market is in constant demand, especially for industries involving infrastructure construction, petrochemicals, and pharmaceuticals. With the development of the global economy, the importance of flanges, as a core component of piping systems, has become increasingly prominent. Their standardized dimensions not only assist engineers in making reasonable designs but also promote safe production across various industries.

Final Thoughts

A flange is an essential component used to connect pipes, valves, and other equipment in piping systems, ensuring secure, leak-free connections. It comes in various types, such as welded, threaded, and slip-on, designed for specific pressure, temperature, and material requirements. The connection method depends on factors like maintenance needs and pressure conditions.

With 15 years of CNC machining service experience, Ultirapid excels in producing high-precision flanges. For example, in a recent project involving stainless steel flanges for a high-pressure system, we delivered tight tolerances and high surface quality. Ultirapid’s advanced CNC capabilities ensure reliable and durable components, making us a trusted partner for industries like aerospace and petrochemicals, where precision and quality are paramount.

Faqs

What Materials Are Ideal For Making Flanges?

The ideal material for making flanges depends on the application. Carbon steel is used for general applications, stainless steel for corrosion resistance, and alloy steel for high pressure and temperature. Cast iron suits lower-pressure systems, while duplex stainless steel is preferred for harsh environments. Titanium offers strength in aerospace, and copper alloys are ideal for marine applications.

What Are The Specifications Of Flanges?

Flange specifications include factors like Nominal Pipe Size (NPS), pressure ratings (e.g., Class 150, 300), and flange type (e.g., weld neck, slip-on). The material (carbon steel, stainless steel) is selected based on the environment, and flange faces (flat, raised, RTJ) determine sealing. Other specifications include bolt hole pattern, thickness, and relevant industry standards for safety and performance.

When Is It Best To Use A Flange Fitting?

Flange fittings are ideal for high-pressure, high-temperature, or corrosive environments, providing a strong, leak-proof connection. They are best used when frequent disassembly is needed for maintenance or inspection, offering easy detachment without compromising system integrity. Industries like oil and gas, chemical processing, and water treatment commonly use flanges for their durability and reliability.